Robotics Institute Reaches Out to Eastern Ohio

WARREN, Ohio – The most recent — and the last — advanced manufacturing hub established under former President Barack Obama’s Manufacturing USA initiative is poised to help create a regional robotics “cluster” across western Pennsylvania and eastern Ohio, officials say.

“This region is ripe because it is basically focused on manufacturing,” said Jackie Erickson, director of marketing and communications at the Advanced Robotics for Manufacturing Institute, or ARM, in Pittsburgh. “The intention around this is building a more productive, more efficient manufacturing base.”

The ARM institute was created as part of the advanced manufacturing program the Obama Administration launched in 2011 to create innovation hubs across the country. These hubs were designed to advance research, education and use of sophisticated manufacturing technology. The first is Youngstown-based America Makes, which focuses on the attributes of additive manufacturing.

Erickson spoke at the Valley Alliance for Science & Technology’s luncheon Friday at the Tech Belt Energy Innovation Center, or TBEIC, downtown.

In January, during the waning days of the Obama Administration, the U.S. Department of Defense awarded $80 million over five years to kick-start the ARM Institute program, along with the commitment of more than 200 partners in the private, academic, and nonprofit sectors whose initial in-kind contributions total $173 million.

“We’re early in the process,” Erickson said, noting the organization is just ramping up and is, for now, working out of the National Robotics Engineering Center at Carnegie Mellon University. “We’re building our team right now.”

Last year, Carnegie Mellon representatives fanned out across the country to identify robotics “clusters” – or areas where there are partnerships that involve government, academic institutions and private industry.

“They talked with small and mid-size manufacturers who all said the same thing: they have to look at innovative ways to thrive or else they’re going to evaporate,” she said. “They won’t be able to compete in a marketplace if they’re not innovative.”

One ARM goal is to help coordinate these clusters – identified as Regional Robotics Innovative Collaboratives such as Silicon Valley or the Boston region, for example – into a comprehensive collaboration that could work with the organization on developing new products.

In the Boston region are three entities that would constitute the region as a RRIC: The Massachusetts Institute of Technology, which is used in research and development; The University of Connecticut, which sponsors a workforce development program; and MassRobotica, a nonprofit organization that advances private development in the robotics industry.

In the Pittsburgh region, Carnegie Mellon, Westmoreland Community College, and the University of West Virginia are on board. “These are still being structured,” Erickson said of the RRICs, and added that an objective is to incorporate this region’s Tech Belt companies and organizations in eastern Ohio into the effort.

“That makes a lot of sense,” she said.

And, she noted, that there are opportunities to work with other innovation hubs such as America Makes and institutions such as Youngstown State University on future ventures in robotics.

Mike Hripko, associate vice president for research at YSU, said the university has partnered with Carnegie Mellon on several occasions. “We’ve done a lot of collaboration with Carnegie Mellon and they’re a pleasure to work with,” he said. “They’re one of our favorite academic partners.”

What is interesting about the ARM Institute is that the business model allows for startups and small businesses to become involved with the organization at a reasonable contribution.

Even though some of the larger players in global manufacturing might take the lead in many of these projects, Erickson said, there is opportunity for small and medium-size companies to become part of these projects.

Yet it’s clear that industrial automation has led to a decline in the demand for workers – especially among large global manufacturers.

As industry becomes more automated, Erickson said, the workforce would need to adapt to and learn new skill sets. However, she emphasized, this opens up a wide range of opportunities as well.

That’s why one of the major thrusts of the organization is to develop a strong workforce development program, Erickson said. “If a new robotics arm comes out, what are the skill sets needed to maintain it, for building it, or integrating it into a manufacturing site?” she asked rhetorically. “So, we have a whole department dedicated to workforce development. It’s not just thinking about the technology, it’s thinking about the people behind the technology.”

These programs could begin as early as grade school, continue through high school and then to two-year colleges or four-year institutions, she noted.

Erickson said the organization is looking to work with industries that focus on aerospace, automotive, textiles, composites and logistics to start.

As of now, no projects are funded through ARM, Erickson said. However, a venture should soon be announced that is connected with the automotive industry.

Dave Nestic, chief executive of TBEIC, said that it’s important for groups such as the Valley Alliance for Science & Technology network with groups such as ARM so its members remain up to speed at any potential opportunities.

“It was put together to foster an environment of innovation among the technology and manufacturing companies in the area,” Nestic said. “Our focus is on engineering, innovation and research and development collaborations.”

Organizations such as TBEIC and the Youngstown Business Incubator welcome new innovation hubs such as ARM because they only strengthen the region’s advanced manufacturing profile.

“We need to figure out how to work with ARM to raise opportunities in the industry,” said Barb Ewing, CEO of the YBI. “There are differences in the technologies and the workforce, but it’s a tremendous resource. It’s an opportunity and it’s something that our businesses need to be aware of so they can succeed and become more competitive.”

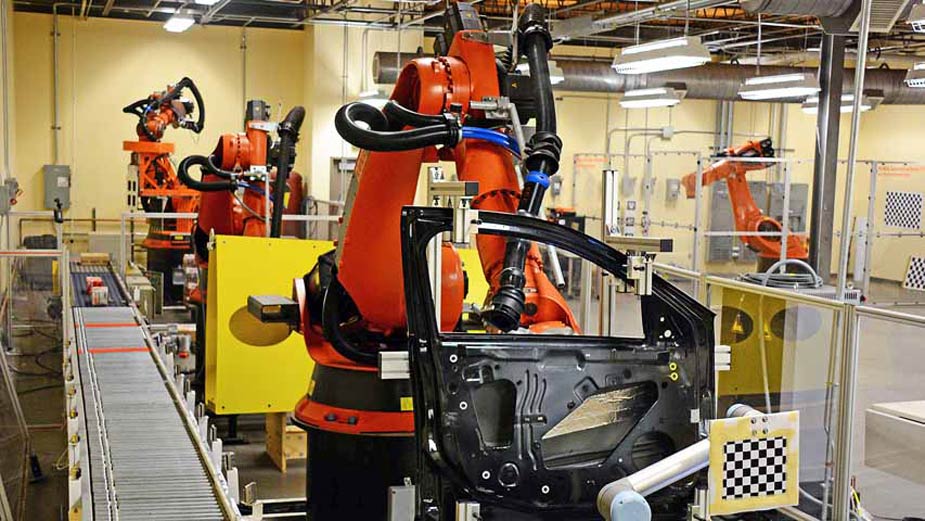

Pictured at top: ARM’s workspace at Carnegie Mellon University in Pittsburgh.

Copyright 2024 The Business Journal, Youngstown, Ohio.