YSU Shows Off Launch Lab to NIST Official

YOUNGSTOWN, Ohio — Using 3D printers in Youngstown State University’s new Launch Lab, engineering students are designing and creating prototypes to make hard-to-find airplane parts for the Air Force Research Lab.

“Some of the parts the Air Force needs are legacy parts, they’re no longer made, so they approached us for help,” explained Ashley Martof, a graduate research assistant in the lab. Once a prototype part is created, the students are using 3D printing technology to create tooling so the part can be manufactured in quantity.

That project and others like it helped to showcase YSU’s expanding role in teaching and researching 3D printing and advanced manufacturing when Philip Singerman, associate director for innovation and industry services for the National Institute of Standards and Technology, visited the region July 24.

Singerman’s visit, closed to the press, came in the wake of an announcement by U.S. Rep. Tim Ryan that NIST had approved a federal grant of nearly $500,000 to fund a hybrid manufacturing consortium that partners YSU with North Carolina University. The Consortium for Advanced Hybrid Manufacturing-Integrating Technologies will develop a plan for integrating additive and subtractive metal manufacturing technology, a combined method known as “hybrid manufacturing.”

The NIST official met with faculty in the College of Science Technology Engineering and Mathematics, visited labs and met with grad students, then toured the Youngstown Business Incubator and America Makes, the National Additive Manufacturing Innovation Institute, in Youngstown.

“Dr. Singerman offered us advice on how to grow and sustain the consortium, and ways that we might go from a planning award, which is what we have now, to a project award,” said Guha Manogharan, assistant professor of mechanical and industrial engineering.

He said Singerman also talked with faculty about an NIST internship program that may be available to YSU students. “This relationship could open doors for internships at the NIST lab, one of largest laboratories in the country,” he said.

Singerman questioned Manogharan and Brett Conner, associate professor of industrial and mechanical Engineering, about how YSU compares to peer universities in the fields of 3D printing and advanced manufacturing. “It looks like YSU has put itself in a very competitive position when compared to other institutions in Ohio,” Singerman said. “Working closely with the Youngstown Business Incubator and America Makes, I can see that YSU is helping to establish a regional innovation cluster in advanced manufacturing.”

The recently awarded NIST grant is the latest in a series of developments related to advanced manufacturing at YSU. In January 2014, the university moved to the forefront of the 3D printing industrial revolution when it cut the ribbon on a new Center for Innovation in Additive Manufacturing in Moser Hall.

Six months later, YSU and the Youngstown Business Incubator were awarded an additive manufacturing grant of nearly $500,000 by the Ohio Third Frontier Commission. In the spring, the Ohio Board of Regents funded a new sintering furnace in Moser Hall that students and faculty to complete the final processing of 3D parts for aerospace, automotive, industrial, energy and medical applications, and another $365,000 grant from the U.S. Department of Defense was awarded in June to purchase another 3D printer.

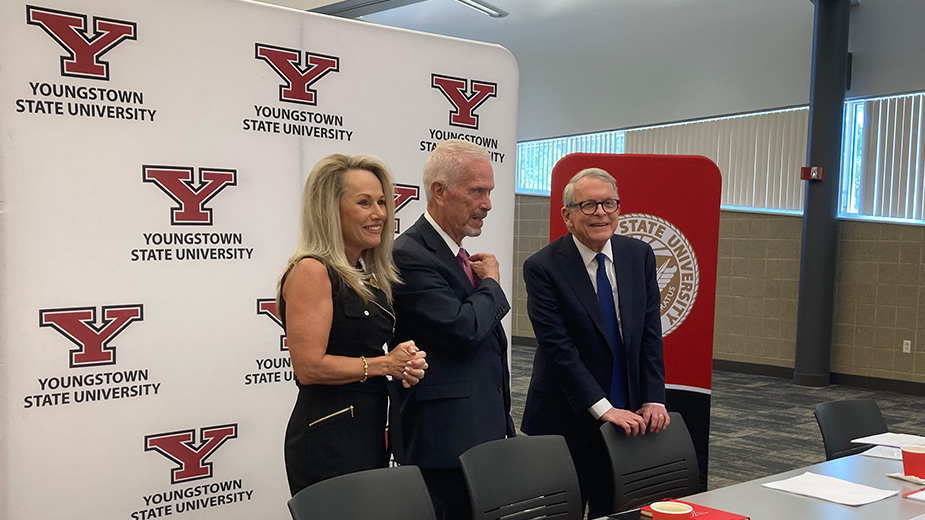

Pictured: Student research Assistant Alec Marsili demonstrates a 3D scanner in YSU’s Launch Lab for, from left, Philip Singerman of the National Institute of Standards and Technology, YSU Engineering professors Brett Conner and Guha Manogharan, YSU President Jim Tressel and Mike Garvey, president of M7 Technologies in Youngstown.

SOURCE: YSU News Center

Copyright 2024 The Business Journal, Youngstown, Ohio.