New Putter, Built Here, Comes into Play

COLUMBIANA, Ohio – Ever an avid golfer, Michael Durina couldn’t quite master one part of his short game: putting. In his basement is a not-so-small collection of putters he’s accumulated over the years.

“I’m not a bad golfer in terms of handicap, but I struggle with putting,” he says. “I have all my life and I still do.”

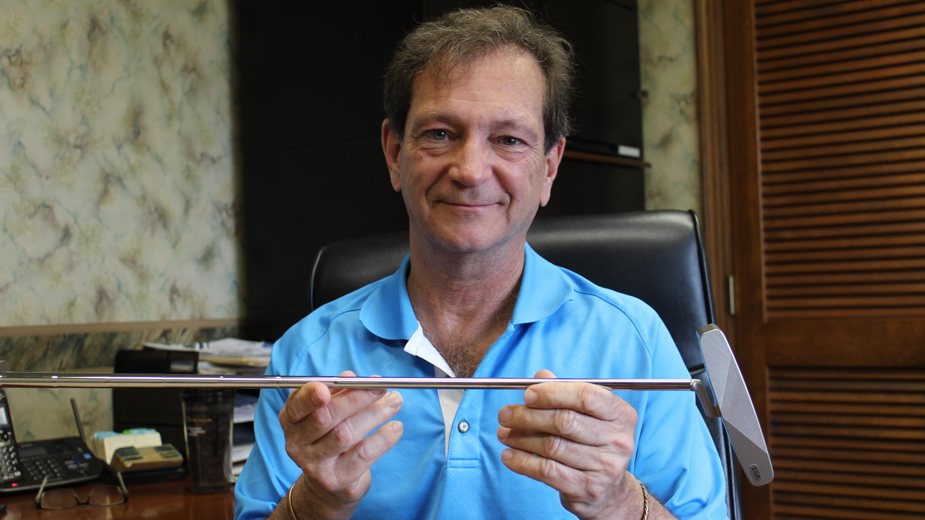

When he isn’t golfing, Durina is the president of Md Plastics in Columbiana. It was there that he saw the innovations happening in 3-D printing and its proliferation in the Mahoning Valley. So, he got to sketching and eventually printed a putter that would work for him.

His design is a big step away from traditional putters: where the shaft is connected to the blade. Most putters with household names such as Callaway and Ping connect one side of the blade with a weight on the opposite end as a counterbalance.

Durina’s design has that connection in the middle of the putter, with weights on both ends. He uses engineering terms to explain the physics involved and the multitude of variables before offering a summary.

“We made the beam stronger in the center and supported it on the ends so that in theory the balance across the face is equal,” he says. “Anywhere across this face, if you strike the ball, you get the same amount of deflection. [The sweet spot] is much more than what you get from a [traditional] cantilever design.”

The design also provides better feedback, he says, because of both the central positioning of the shaft and weight of the club, about three-quarters of a pound. Weights can be added to fit each golfer’s preference.

“I looked at some of the best putters in the world … and they all have a certain weight that’s good,” Durina says. “[Club designer Ralph Maltby] wrote a book and I looked at his data and right around 345 grams is right in that spot that’s really good. With that weight, you get the best feel and feedback.”

When it comes to Durina’s play, he says the club has helped his short game. The best round he’s ever shot – three under par over nine holes – came when he was using his own putter.

After two years of working on prototypes, Durina developed his own brand – Envisage Golf Co. – and started selling the clubs in April. Like the model he made for himself, the putter is made of 3-D-printed metal.

Beyond just the design of the club, Durina hopes that the ability to customize putters will help Envisage take off. In the future, he wants to make the club’s design an open source, to post it on 3-D printing sites and allow golfers to design their own version of the putter or attachments such as visual alignment tools. Customers can also have names or logos – such as a company or alma mater – inset on the back of the club.

“It’s a sound design. It feels good. We think it’s world-class in terms of feel and balance,” says Durina of his new-on-the-market putter. “I also think it has the possibility to be marketable. It can be custom-printed so you can get names and company logos on it. It’s not the thing you’ll get someone for a bachelor party and stick it on the shelf.”

Pictured: Md Plastics President Mike Durina.

Copyright 2024 The Business Journal, Youngstown, Ohio.