$445K Awarded for Study of 3D-printed Material Fatigue

YOUNGSTOWN, Ohio – The National Science Foundation awarded $445,515 to a team led by a Youngstown State University professor to explore the fatigue behavior of 3D-printed materials.

The funding, known as a major research instrumentation grant, will support the acquisition of instrumentation designed to test both the dynamic stiffness – or how much a material deforms when force is applied – and the lifetime of a material subjected to external forces.

The machinery will be housed at YSU. Alexander Pesch, assistant professor in YSU’s Rayen School of Engineering, is the project’s principal investigator.

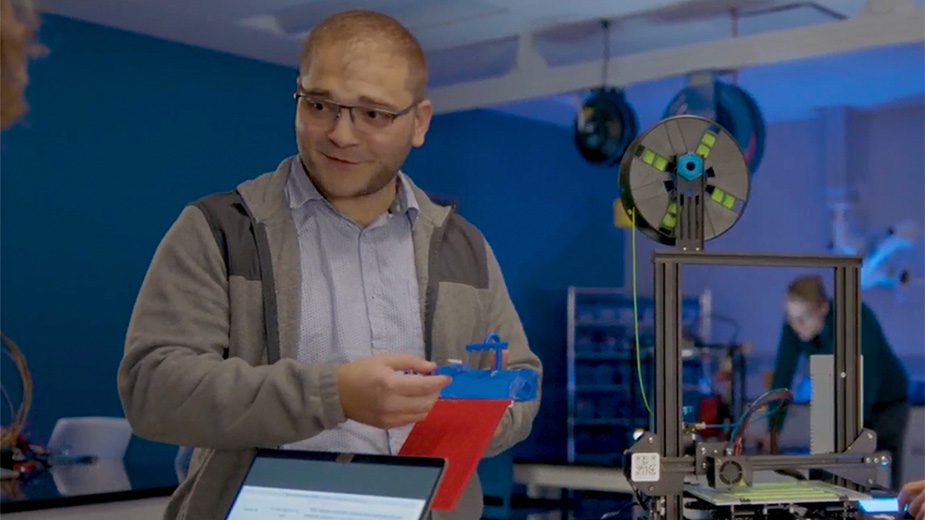

The team includes Matthew Caputo, associate teaching professor of engineering at Penn State Shenango.

Caputo’s involvement in the grant proposal is focused on the research capabilities of additive manufacturing, better known as 3D printing, of nickel-titanium shape memory alloys. SMAs are a unique class of materials that have the ability to “remember” their original shape after deforming.

“Think of a metal coat hanger permanently deforming when it’s pulled and twisted,” Caputo said. “If the coat hanger was made with nickel-titanium SMA, the coat hanger would return to its original state after being deformed.”

According to Caputo, the material has difficulty in manufacturing processes, especially in complicated shapes. However, there is significant interest in using 3D-printing technology as a method to produce SMAs.

“There has been some success [using additive manufacturing technology], but material fatigue, one of the most important aspects for applications, has yet to be fully explored,” Caputo said.

Fatigue, in the instance of manufacturing technology, is how well a material responds mechanically to a cyclic load. A portion of the grant was used to purchase an Acumen 12 electrodynamic test system, which is used to perform dynamic and static tests on different materials.

“Nickel-titanium happens to respond favorably to fatigue cycles,” Caputo said. “The focus of my work will be on creating 3D-printed nickel-titanium parts using additive manufacturing technology and testing their fatigue responses.

Students will have access to the state-of-the-art equipment as well. Local manufacturing industry representatives will be invited to participate in new research and development initiatives, enabling students to be involved in hands-on learning opportunities with real-world benefits, according to Caputo.

CREDIT: Penn State Shenango.

Pictured at top: Matthew Caputo, associate teaching professor of engineering at Penn State Shenango, is researching the fatigue behavior of nickel-titanium shape memory alloys. (Penn State | Creative Commons)

Published by The Business Journal, Youngstown, Ohio.