From Tire Factory to ‘Bounce’ Hub

By Dan O’Brien

AKRON, Ohio — A half century ago, the empty 22,000-square-foot space where Douglas Weintraub now walks would have been filled with industrial machinery as hundreds of workers swarmed the factory floor of what was once the B.F. Goodrich Co. in downtown Akron.

“You’re standing in a 150-year-old tire manufacturing plant,” Weintraub, the CEO of the Bounce Innovation Hub, says as his voice echoes across the recently gutted first floor of the nine-story building.

During the early 1980s, Goodrich abandoned its manufacturing operations here and a decision was made to use the entire building to help reinvigorate the local economy by nurturing small, innovative companies through which young entrepreneurs could make a difference.

In the more than 30 years since the city of Akron helped develop the Akron Global Business Accelerator – one of the oldest business incubators of its kind in the country – the effort has continued to diversify and attract new companies with innovative and exciting ideas, Weintraub says.

Today, there are 52 portfolio businesses that range from startups to seasoned scale-up companies ready to expand and increase their workforce. And, late last year, the organization was renamed the Bounce Innovation Hub – a nod to the technological innovation underway in Akron.

Douglas Weintraub, CEO of Bounce Innovation Hub, looks over plans for a $2.5 million renovation of the incubator.

Part of this transformation begins on the first floor, Weintraub says. Work is in progress to renovate this space into a multi-use innovation center, where the public can congregate to brainstorm new ideas, experiment with product innovation or host an event.

“The goal is to create an environment that is a combination of many buildings that you find all over northeastern Ohio, but under one roof in Akron, Ohio,” Weintraub says.

Plans for the first floor include the development of a cafeteria and restaurant at the front of the building at 526 S. Main St. Among the other additions are a maker space, a craft lab, an electronics lab and tech lab slated for the rear of the new space – replete with CNC machines, lathes and 3D printers. The remainder of the floor will be reserved for office space, conference rooms and an area that would be used for presentations, workshops, lectures or other events. There’s even a plan to host the University of Akron’s e-sports teams, one of the latest rages in college pastimes.

Weintraub says there are plenty of opportunities in northeastern Ohio to access maker spaces, e-sports terminals and tech labs, but none are consolidated to a single floor.

“Our focus is to transform the space into an innovation hub,” he says. “It’s a place where people can congregate in the restaurant, in the co-working spaces and the events space.”

Weintraub equates the first floor development as an introduction to the resources that the Bounce Innovation Hub has to offer. “This project has created a lot of buzz, and people have come in and found that there are eight other floors of space and opportunity,” he says. “We’re doing work with startups and scale-ups.”

Weintraub says he recently met with companies that range in size from two and three people to ones that employ 25, where the average salaries are $50,000 or more. “When you start to look at those kind of companies and add those numbers up, it’s worth multimillions of dollars in payroll, which then translates into hundreds of thousands of dollars back to the city.”

As such, Bounce has successfully attracted a host of different entrepreneurs and businesses that encompass disciplines as diverse as fine arts and biomedicine. That makes for an intriguing environment for both prospective tenants and investors, Weintraub says.

Larger companies in the area, he continues, are interested in identifying some of the technologies or products under development by the Bounce Hub’s portfolio firms and ascertain whether they would make a sound investment opportunity. And it appears that plenty of opportunities exist as many of these young companies strive to change, or at least add to, the region’s entrepreneurial landscape.

As one walks from the elevator on to the eighth floor of Bounce, you’re met with an unusual, bright purple glow that emanates from a room directly down the hall.

It’s enough to arouse the curiosity as to what could be going on in there. Is it an intricate experiment with lasers? Or are they visual artists working with dazzling photovoltaic displays?

In this case, the purple glow is the result of light-emitting diode, or LED, lights six tiers high that are helping to nurture thousands of greens and vegetables for harvest indoors.

“We specialize in controlled-environment agriculture,” says Vincent Peterson, president and CEO of Vigeo Gardens. “The idea is to control what’s going on inside the plant structure so you could grow whether you’re in a climate where there’s water deprivation or cold.”

Peterson says the idea to build Vigeo Gardens occurred to him while studying biomedical engineering at the University of Akron. He and another friend from college had heard about the nutritional value of microgreens, that is, vegetables and herbs that are harvested at the first sign of leaf growth. The greens are smaller than baby greens, but larger than sprouts.

Initially, Vigeo targeted the health community such as hospitals as a potential customer base, but was rejected. “So, we made the pivot from a highly regulated market to the restaurant, grocery and family farm industry,” he says.

Vigeo Gardens is capable of growing 27,000 full vegetable plants that it can turn over 14 or 15 times a year, Peterson says. Thousands of microgreens are harvested every week at the company.

The plants are grown through an elaborate hydroponic system that is stacked six tiers high, each tier filled with trays awash in LED light. Water mixed with nutrients is circulated through channels underneath each tray, and is recycled to optimize resources. Once the greens are harvested, they are packaged and shipped out.

Vigeo’s 12,000 square feet at Bounce provides the equivalent of about a quarter acre of grow space, he says.

The company was accepted into Bounce in 2015 and Peterson says that services such as business counseling, reasonable rental rates and other resources in the building helped the company become competitive in the marketplace. “We really didn’t know much about the operational side,” he says. “Bounce has allowed us to ramp up and take more time in developing a plan of execution. It enables businesses to buy more time.”

More than 200 employees work out of the Bounce Innovation Hub today, says Jessica Sublett, Bounce chief operating officer. Of the 52 company tenants in the building, about 35 are in the incubator stage, while the rest would be considered more mature scale-up companies.

And more of these firms are expected soon, Sublett says.

“We recently signed a deal, she says, with Companion Labs,” a local software scale-up company that optimizes social media marketing. “They’ll move into the ninth floor, and are expected to bring in another 20 employees.”

In addition to housing tenant companies, Bounce is also home to support organizations such as the Ohio Small Business Development Center, a procurement technical assistance center in affiliation with Ohio University and a women’s business network.

Other companies in the building have developed ideas and research that reflect changes in law and society.

Triple Beam Technologies, for example, is working on a device that would essentially be able to test an individual on site for potential marijuana use, says Justin Stitzlein, business development associate.

Stitzlein’s mother, Kathy Stitzlein, developed the idea as the basis for her Ph.D. dissertation at the University of Akron. “With the legalization of marijuana – medically in Ohio and recreationally in other states – there’s pressure to have a quantitative test for THC,” Stitzlein says. “The market would be any law enforcement organization in these legal states.”

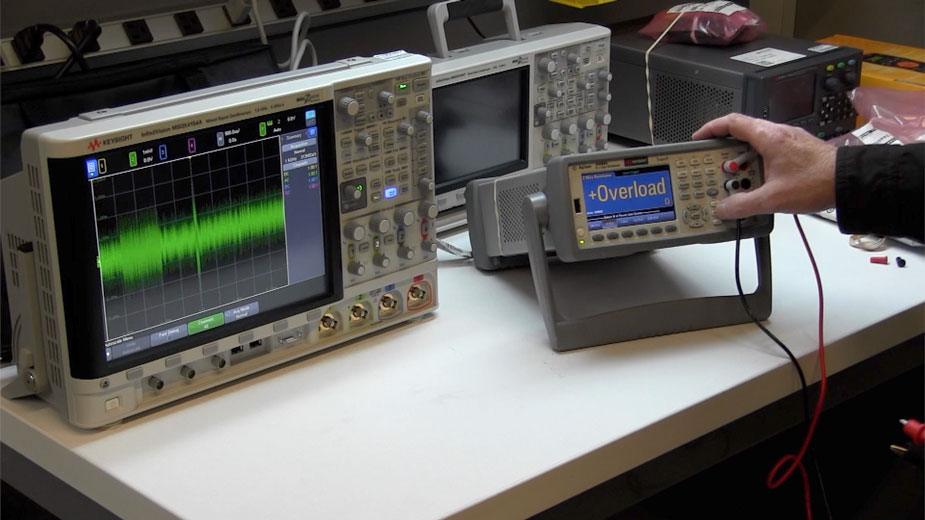

Justin Stitzlein says his firm, Triple Beam Technologies, is developing a device to test individuals for marijuana use.

What is critical is the level of creativity and technical innovation that emerges from many of these small companies as they prepare to bring their ideas to the commercial market.

“We manufacture a fibrous material, a dry adhesive that’s not sticky and does not cause damage,” says Rebecca Kuznarsky, lead product developer at Akron Ascent Innovations. The company has taken technology pioneered at the University of Akron and is in the process of transitioning this technology for commercial use.

The adhesive is undergoing different phases of testing at the moment, but the first objective is to apply this material to the back of printing paper, Kuznarsky says.

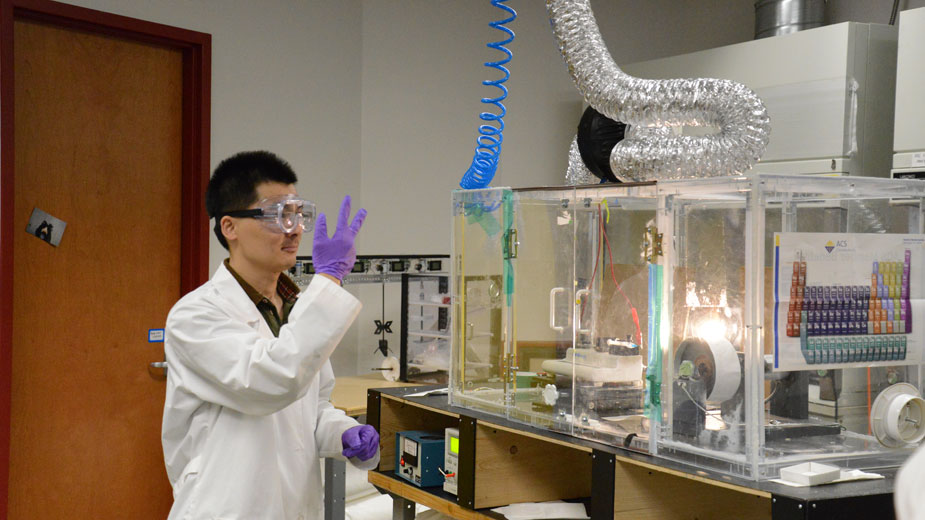

Fei Wang demonstrates how Akron Ascent Innovations makes its dry adhesive product.

As a demonstration, she peels off the backing of a sheet of paper, exposing the company’s adhesive. The dry adhesive bonds with the wall, and does not lose its adhesion when it is removed or relocated.

Barry Rosenbaum, president and CEO of Akron Ascent, says his company is very happy with the support it’s received through Bounce. “The services we’ve received have been fantastic – there are six or seven startups from the University of Akron and we recommend it.”

Rosenbaum has worked with the university’s tech transfer office in order to bridge the gap between developing the concept in an academic environment and a practical business. “My role is to try to commercialize research,” he says.

He says the market interest in this technology is strong, noting there is an array of applications for adhesive technology that isn’t sticky, doesn’t damage surfaces and is repositionable.

“We formed the company and I became the president of the company,” he says. “What fun.”

Copyright 2018 The Business Journal, Youngstown, Ohio.

Copyright 2024 The Business Journal, Youngstown, Ohio.