Business Flows Along Ohio River, Like it Has Since 1800

WELLSVILLE, Ohio — During the 1800s, the Ohio River served as an important mode of transportation not only for residents who lived along its banks but for shipping goods, and that trend has not only continued but escalated over the past 200 years.

Residents and tradesmen realized early on it was not only faster but less expensive to send goods by river than by horse and wagon through the Appalachian Mountains.

The tributaries and canals that contribute to the river along its path create a total of 2,800 miles of navigable waterways, which today are all part of the U.S. Inlands Intracoastal Waterway Systems that serves 35 states from the Atlantic seaboard to the Gulf Coast.

As with their early counterparts, businesses still find this system of waterways a convenient, less expensive and quicker way to transport goods. Approximately 630 million tons of cargo valued at $73 billion are moved along it annually, according to a 2013 statewide freight study prepared for the Ohio Department of Transportation.

At the Wellsville Intermodal Facility, Pier 48 Stevedoring LLC President Larry Heck has also found the river to be an accommodating mode of transportation, as well as a way of life for the past 43 years.

Heck spent 40 years with North Star Coal Co. and Parsons Coal Co., both riverside operations in East Liverpool, before starting Pier 48 in 2012, following in the shoes of his father, Dave Heck, who also spent a large part of his life working on the river.

Heck started right out of high school as a mechanic and made his way to general manager of Parsons and assistant vice president of North Star before branching off into his own business at the intermodal facility.

Sitting in his Wellsville office trailer as trucks continuously roared by, Heck says, “We started this from the ground up; this office, the equipment. It goes hand in hand with the [Columbiana County] Port Authority.”

Pier 48 was launched with one overhead bridge crane, unloading an average of two barges per month. Today, after consistent purchases of equipment and upgrades to the operation, it boasts a unique conveyor system that allows trucks to be loaded directly from the barges.

Part of this system is the result of a $4.2 million expansion completed in 2016 with the port authority.

“Today, we can do up to 30 barges a month and have sometimes peaked out at even more,” Heck says.

Having two cranes and the conveyor system at his disposal is instrumental in the increase in production, enabling products to be moved back and forth quicker.

“We can do steel on one crane and bulk materials on another,” he gives as an example.

Soybeans are one of Pier 48’s main products, coming in from New Orleans after being shipped to the United States from Turkey and India.

He says the shipments – averaging about 12 barges weighing 18 tons each – take about 21 days to reach his facility in Wellsville from New Orleans, after which they travel to a Salem company where they are processed into oil and organic chicken feed.

Six to eight barges, each loaded with about 1,600 tons of steel, are unloaded at Pier 48 per month, shipped by truck to locations in Pennsylvania and Youngstown for the most part.

The fracking industry has also increased traffic on the river, according to Heck, who says the industry averages between 22 to 30 barges at a time, filled with barite, a mineral used in the drilling process.

Heck says with the $6 billion Shell cracker plant under construction up river in Monaca, Pa., and another being eyed for Belmont County downriver, he expects to see more of a need for barite.

“That will increase, which will keep [this business] going,” Heck predicts.

Among the company’s nine employees is manager Ron Thrasher, who started with Pier 48 eight years ago as a crane operator and now deals with customers on a daily basis.

While flooding in Louisiana has caused some delays in shipping, which has had to be addressed with customers, Thrasher says they have been understanding. “They know we have nothing to do with the barges getting here,” he says.

Having worked more than 20 years on the Ohio River himself, Thrasher says, “I just like being on the river and the barges, and I like dealing with customers. I like my job, and I like working for Larry. I always tell him I’m not going anywhere.”

Heck says the county port authority has been “instrumental” in working with Pier 48 and other companies in promoting economic development, and the 46-page Ohio River Terminals Analysis report released in May 2013 by the Ohio Department of Transportation would seem to concur.

The report refers to the Columbiana County Port Authority as “very active” in regard to waterborne transportation, according to a freight study conducted at the time.

It was also noted that the CCPA system “feeds the industrial base of northeast Ohio,” and, of combined with the 10-county Port of Pittsburgh system, could constitute the seventh-largest port in the country.

Pointing out that Columbiana County is located in the heart of the Cleveland-Pittsburgh industrial corridor, the report states it is “well-suited to serving the region’s cluster of industries of automotive, aerospace, polymers, chemicals and metals.”

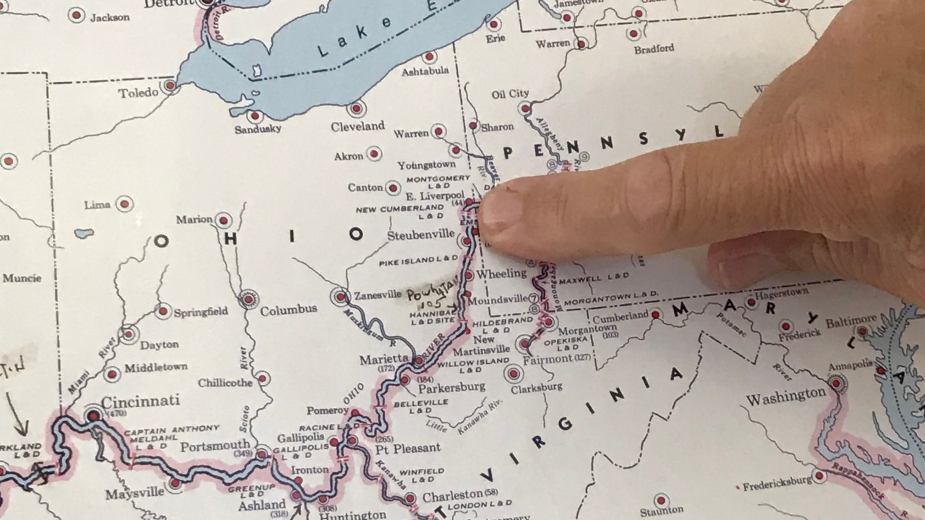

Pictured above: Larry Heck points to where the Wellsville Intermodal Facility is positioned along the Ohio River.

Copyright 2024 The Business Journal, Youngstown, Ohio.