YOUNGSTOWN, Ohio – The restart of a Youngstown steel mill in the mid-1980s would lead eventually to a globally recognized economic development project taking place in the Mahoning Valley decades later.

“Mini-Mill to Be Born Again” declared the headline of the Youngstown Business Journal’s March 1985 edition. North Star Steel, a subsidiary of Cargill Inc., was planning to buy the vacant Hunt Steel (Youngstown Sheet & Tube’s former Brier Hill Works), if U.S. Bankruptcy Court approved the Minneapolis-based company’s $22.5 million offer. The cities of Youngstown and Girard were being asked to enter into enterprise zone agreements with the company.

Bruce Smith, project supervisor for the Ohio Department of Development, described the acquisition as “a good business decision” for the company. Mini-mills use scrap steel in their process and North Star owned several scrap yards in Ohio and Michigan. So, shipping scrap material to a local plant for processing would be more feasible than shipping it to its facilities in Texas and Minnesota, Smith said.

The area’s skilled workforce also was viewed as an asset. “We think steelworkers can be easily retrained onto the modern technology North Star represents,” he said.

Two years later, our March 1987 edition reported that millions of dollars had been poured into the plant, replacing high-tech equipment that Hunt had installed and returning it to its German manufacturer, and installing a state-of-the-art pipe mill designed and manufactured in Italy. Once fully operational, the mill was projected to employ “some 300 workers.”

“We will be pouring pipe in December,” predicted a confident Gary Giovannetti, vice president and general manager of North Star Ohio. The company already was employing more than 90 workers on a two-shift, five-day-a-week basis. The scrap metal furnaces were trying out solid squares and rectangles to be shipped to North Star’s Calvert City, Ky., operation, turning out 12,000 tons per month.

North Star Steel Ohio ended up producing its first seamless, oil-well tubular casing in Youngstown in early February 1988.

The fate of the North Star Mill – indeed, of the Valley itself – took a twist in 2002 that few could have anticipated. In July of that year, Cargill sold the operation to Vallourec & Mannesmann Tubes, a French-German venture, and Sumitomo Corp., a Japanese company, for $380 million.

“The transition went smoothly, and they were very straightforward with us,” steelworker Jack Berry said in December 2002’s lead story, “Foreign Firms See Opportunity in Valley’s Steel Industry.” North Star would also be rebranded as V&M Star to reflect the new ownership.

About 18 months before V&M would make a pivotal local investment in February 2010, Walt Good, then vice president of economic development at the Youngstown/Warren Regional Chamber, and other local officials were called into a meeting with Roger Lundgren, V&M’s president.

The topic was a project code named “Tomahawk,” an opportunity that the company was considering “in terms of a major investment,” Good says.

“It was clouded and shrouded in secrecy, but he wanted to introduce the concept of what they were considering,” he recalls.

“At the end of the presentation, to be honest, I was blown away by what they were proposing, because we hadn’t seen a proposal of that type of investment in the steel/metal industries in many, many years,” Good remarks.

Work to bring the project to Youngstown continued for months, as The Business Journal reported in online stories. The city of Youngstown acquired land for the project in 2009, for which the city eventually was reimbursed more than $6.4 million, even as company officials continued to weigh where it might site the proposed new operation. The mill was designed to capitalize on advances in oil and gas drilling technology that increased demand for the products the company made.

Local prospects for the project received a significant boost when Gov. Ted Strickland, in early 2009, directed $20 million in federal transportation stimulus funds from the American Recovery and Reinvestment Act of 2009 as well as state funds to assist with site improvements and a rail line relocation that was key to the making the project work at the site.

Good, now a managing director with Team NEO, remains convinced today that those funds were crucial to making the project happen here.

“There were significant site grading issues that needed to be addressed, and there still were substructures from the previous mills that needed to be addressed, as well as a massive amount of rail infrastructure that had to be brought to the site,” he says.

Progress did not always advance smoothly.

Lindgren had made clear that for the project to move forward, he preferred that the entire project be located within Youngstown’s city limits, which led to months of often heated discussions with officials in neighboring Girard, where some of the land needed for the project was located.

At one point, V&M had even set an August 2009 deadline for the cities to reach an agreement after Girard Mayor Jim Melfi had indicated he was unwilling to permit the land in question to be annexed to Youngstown.

“I am still not for moving boundaries but there’s a deal here and the deal is very important to both cities and the Mahoning Valley,” Melfi said following a meeting with Lindgren, U.S. Rep. Tim Ryan and Youngstown Mayor Jay Williams.

“There were definitely times that we collectively wondered whether we were going to be able to successfully help the company make the project happen in the Valley,” Good says.

Other concerns arose about the cost of the site itself, and a switch to property in the Youngstown-Campbell corridor was proposed.

In October 2009, Williams met in Paris with key executives of V&M Star’s holding company to make the case for Youngstown.

By the following month, city councils in both Youngstown and Girard had signed off on the border adjustment.

V&M made it official during a Feb. 15, 2010, news conference at Youngstown State University’s DeBartolo Stadium Club. The company would build a $650 million rolling mill employing 350 to complement its existing pipe and tube operation, where 500 workers already were employed. A decision on a $320 million melt shop was yet to be made.

“I am pretty excited about this,” Lindgren told the assembled government and community leaders. “My knees are shaking.”

A few months later, in May 2010, President Barack Obama – who had championed the Recovery Act and signed it into law – spoke at V&M Star.

“Right here, in the heart of the old steel corridor, where some never thought we’d see an investment like this again, they’re placing their bet on American manufacturing and this community,” Obama said following a brief tour of the plant.

Ground was broken in late June 2020 for the new seamless pipe mill.

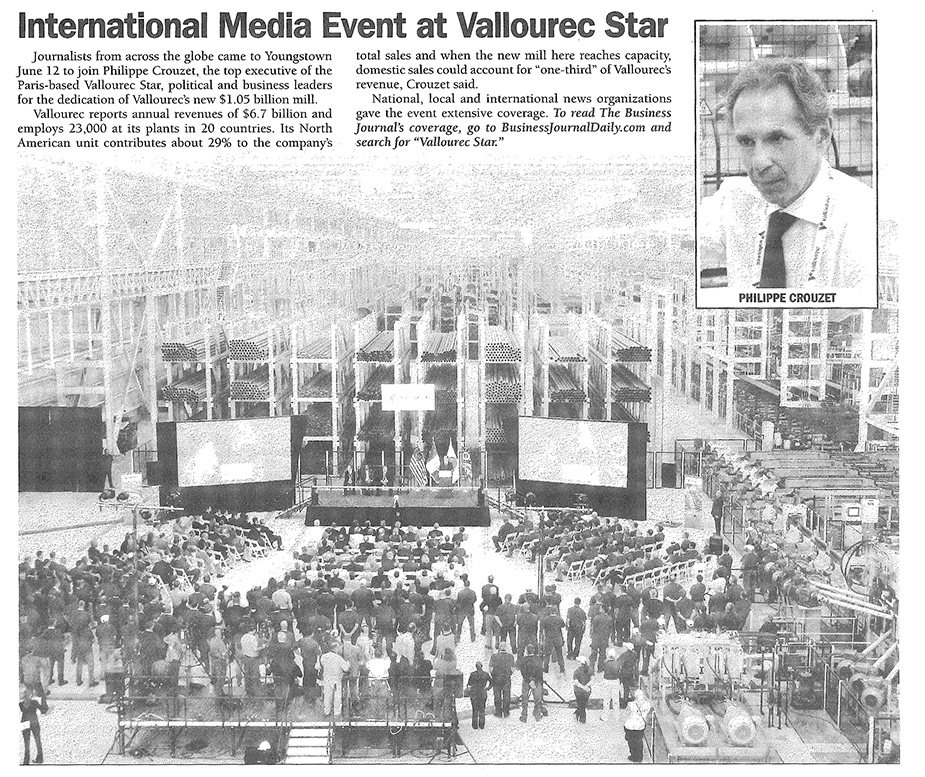

Philippe Crouzet, chairman of Vallourec’s management board, said the “collective success” of the company “will be greatly influenced by what happens here.”

He also cited the “unprecedented collaboration” among government and business leaders as being critical in Vallourec’s decision to choose the Mahoning Valley site for the mill.

A dedication ceremony was held in June 2013 for what was now the $1.05 billion seamless pipe mill, which had produced its first pipe the previous November. Earlier in 2013, V&M Star adopted the Vallourec name as part of a companywide branding and identity strategy.

But Vallourec wasn’t finished.

In November 2011, at the Youngstown/Warren Regional Chamber’s Youngstown Ohio Utica and Natural Gas Conference, it was announced that VAM USA LLC, a manufacturer of premium pipe connections it was a partner in, intended to develop a new threading mill.

In March 2014, Youngstown officials confirmed that VAM would move ahead with the $81.6 million pipe threading mill in the former Genmark steel building and on additional property it purchased from the city, and the plant went into production the following May. Vallourec’s pipe manufacturing and threading operations remain active today in Youngstown. Employment is approximately 1,000 workers, including temps and subcontractors, a Vallourec spokeswoman says.

Pictured at top: Vallourec’s local operations today employ approximately 1,000 workers, including temps and subcontractors.