LEETONIA – When Dave Caruso was hired at Haltec Corp. in 1987, the company had all of 10 employees and $1 million in sales.

Caruso – today Haltec’s executive vice president and a part of its ownership group – says the company now employs more than 250, with sales of $100 million from customers in more than 50 countries.

“A lot of that growth has been in the last 10 years,” Caruso says. “Probably half.”

Haltec, based in Leetonia, has earned a name for itself in the global off-road industry as a manufacturer and supplier of heavy duty tire valves and inflation systems that are used by equipment manufacturers such as Caterpillar and Komatsu.

The company has carved out a presence in the mining, construction, aviation, commercial fleet, and light truck markets.

Haltec is also the sole supplier of gauges used by the National Football League to calibrate proper inflation levels for footballs at game time.

Haltec has operations in Leetonia and Salem, Ohio, as well as plants in Brooksville, Fla., and Limerick, Ireland.

The mining industry is the company’s bread and butter, Caruso says.

Haltec’s inflation valves – some of them complex – are affixed to the giant tires on vehicles used to extract minerals and materials from mines located all over the world.

It’s success in the global market, as well as the company’s efforts to recruit and grow its local employee base in northeastern Ohio, has earned Haltec recognition as the U.S. Small Business Administration’s 2024 Great Lakes Regional Exporter of the Year. Employees of the company and representatives from Youngstown State University and the Ohio Small Business Development Center’s Export Assistance Network were on hand May 8 to celebrate the award.

“It’s fascinating to think that this small business in Ohio is producing these products that are getting exported to over 50 different countries across the world,” says Clark Bihag, the SBA’s deputy district director in Cleveland. “That is a remarkable feat.”

The SBDC’s Export Assistance Network at YSU nominated Haltec for the award, says Mousa Kassis, director.

One component of the Export Assistance Network is to facilitate internship programs for those seeking a career in international business or trade, he says.

“They’ve participated for six years hosting our students and offered jobs to five of our students,” he says.

Kassis says Haltec’s dedication to its employees, positive customer responses, plus adopting a proactive approach to exporting as part of its overall growth strategy, are among the reasons the company was nominated for the award.

“Haltec is a team player that’s forged a great relationship with YSU,” Kassis says.

Michael Adelman, national account manager at Haltec, says the company will employ its eighth intern from the program this summer.

“They’ve been extremely beneficial helping us understand import and export procedures, they’ve helped with our duty drawback program, and have just been a big benefit,” Adelman says. “Additionally, they help us do market research in areas of the world that we don’t quite have the resources or the ability to really understand the industry.”

On the domestic front, Haltec manufactures valves and inflation systems for clients across the country.

The company, for example, is the dedicated vendor of inflation systems for all Love’s truck plazas in the United States.

Perhaps the company’s most high-profile client is the NFL, Adelman says. “The technology we use to inflate tires is the same technology we’re using to inflate footballs,” he says.

The company was approached by the NFL in the wake of “Inflategate” – the moniker given the controversy over former New England Patriot quarterback Tom Brady’s suspension after it was discovered that footballs he used were deflated at levels below NFL regulations.

“The NFL came to us, asked us for a solution,” Adelman says.

“Now, we’re managing a football from when it’s manufactured at the Wilson facility in Ada, Ohio, all the way until it’s used on game day in an NFL stadium,” he says.

Adelman says the company plans to make upgrades to its software and technological capacity as it expands. “We’re just staying ahead of the industry and what we manufacture,” he says.

Haltec manufactures thousands of components at its Leetonia plant every year that are used to manufacture these heavy-duty valves, says plant manager Jeff Walker.

The company constructed the Leetonia plant in 2019. Haltec’s previous Salem location is today used for distribution. The new plant is specifically designed to house 22 computer-numerically controlled, or CNC, machining centers and two manual processes, Walker says.

“Our product line is super modular,” he says, noting the company manufactures approximately 600 different products for small and large uses.

Once components are machined, they are heat-treated in an oven powered by ammonia nitrogen and are then prepared for final assembly.

“We do have a great leadership team here,” Adelman says. “It’s really a family environment here where everyone is working together, everyone trying to improve how Haltec grows the company.”

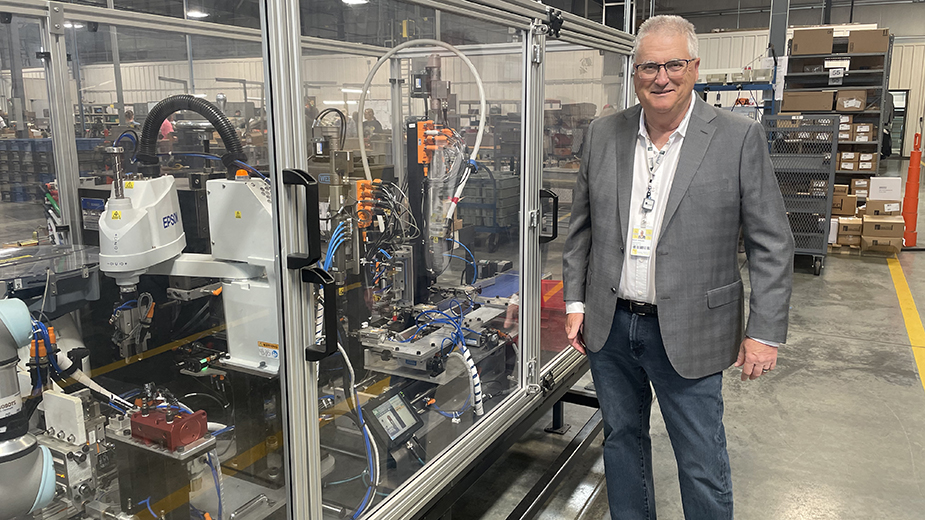

Pictured at top: Dave Caruso, Haltec executive vice president, stands next to automated valve finishing equipment at the Haltec plant in Leetonia.