BROOKFIELD TOWNSHIP, Ohio – The Industry 4.0 lab at Brookfield High School bears more similarities to a manufacturing plant than a traditional classroom.

Students huddle around robots, pneumatic systems, and electrical and programmable controller systems.

Junior Ryland Mihalcin is taking the elective for the 10th time.

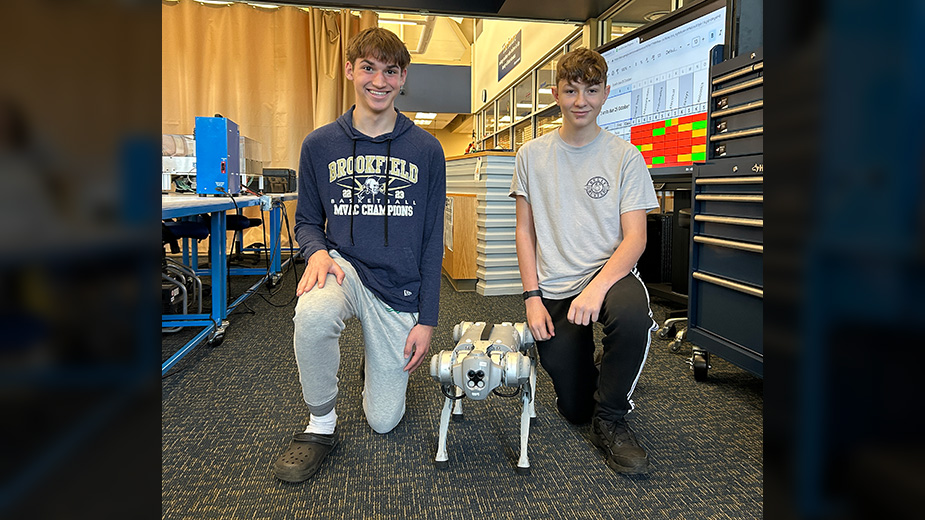

“It’s really fun,” he explains as he pauses from working with the robotic dog in the lab. “This is the one class I look forward to. I enjoy being here.”

It’s different from a traditional classroom and Ryland can problem solve at his own pace.

“If I’m getting too frustrated with one thing, I can turn around and there’s another thing I can work on and try to fix,” he says. “There’s always something to do and it stays interesting.”

And the course enables students to earn industry-recognized credentials. Ryland has racked up several.

“I have basic operations – silver and gold – robotics operations, electrical relays or something like that,” Ryland relays

Bahr Martin estimates he’s taken the class seven times.

“Now that I’m on my sophomore year, I can mess around with robotics too,” he offers. “As he was saying, it’s very self-paced.”

Initially, he wasn’t informed about what the Industry 4.0 class was but he signed up for robotics.

“But then [instructor Josy] Ms. Chu was telling me all about how it isn’t just like grease and grime. It’s an actual application and in many different parts of the industrial world,” Bahr says.

“She was telling me about how all this works. It was pretty much mind blowing.”

Bahr has been interested in robotics for some time but didn’t realize that’s part of industry.

“She showed me all the awesome things and now I have my basic operations silver and gold [credentials],” Bahr says. “I’m doing college work through the University of Akron and YSU to go toward an associate’s degree program.”

All of the specialist courses for the automation degree he’s pursuing are going to be in the industry class.

“The whole point of the 4.0 is the fourth industrial revolution,” says Chu, instructor of Industry 4.0 and robotics. “The automation of different manufacturing processes, different industrial processes…Plants are running more on their own rather than people running them.”

INDUSTRY TAKES NOTE

Business and industry are noticing the skills Brookfield students are developing.

“In fact, we had a student, they got several of those different credentials, and he got hired last year,” Chu says.

The student was a senior last year and earned several credentials. Representatives with a company visited the class and he impressed them with his skills and knowledge. They offered him a job.

“And they’re actually helping him go through school as well right now,” Chu says. “So, he works there. He’s getting his electrical engineering degree at Youngstown State.”

The semester-long class is available to students in ninth through 12th grades and it fills up.

“It’s a class on advanced manufacturing,” Chu explains.

“It’s designed to prepare students for any sort of manufacturing environment. They could go work in industrial maintenance. They learn a little bit of everything, a little bit about electrical, a little bit about pneumatic circuits, fluid power,” she explains.

The class covers basic hand tools too.

“Some kids come in here and they’ve never even seen a ratchet before,” Chu says. “They start there, being able to apply those skills in a manufacturing environment.”

NEW TERRITORY

With just under 1,000 students – about 300 in high school – the Brookfield Local School District is a pioneer in offering such electives.

“At the time, nobody was doing this,” says Superintendent Toby Gibson. “I think there might have been a couple of tech centers that were starting the program, but nobody had this. And there weren’t any K to 12 schools [in Ohio] that had an advanced manufacturing program.”

This marks the third year for the course and the district received a $1.2 million state Innovative Workforce Incentive grant to buy the equipment and outfit the lab. That same grant enabled creation of a career-based science, technology, engineering and mathematics program at the district. The program stretches into elementary and middle school grades.

“We were trying to create programs that kind of push kids into critical thinking, provide critical thinking skills, problem solving, as well as things that are hands on, instead of sitting in class and lecturing,” the superintendent continues.

LISTENING TO INDUSTRY

The program was also a response to industry needs.

“One of our main goals was to bridge education with industry to prepare our students so we can meet the demands of today’s workforce and so they can excel in their chosen career paths,” says Kristen Foster, district director of teaching and learning.

The school district has a business advisory council where business and industry professionals meet regularly with district personnel and communicate the skills they need in the workforce. A career counselor from the Educational Service Center of Eastern Ohio in Canfield also played a role in Brookfield pursuing establishment of the Industry 4.0 lab.

In applying for the initial grant, the district worked with a vendor to determine the equipment needed.

The Mahoning Valley is becoming something of a technology belt, Gibson notes, pointing to the Youngstown Business Incubator, and the Intel plant under construction near Columbus that will bring more satellite industries to the state.

“So, advanced manufacturing and industry 4.0 seemed to be the direction to go with how manufacturing is changing in this 21st century,” the superintendent explains.

Besides students earning industry-recognized credentials while in high school, they’re learning soft skills too. Companies and other school districts visit the lab and representatives talk to the students about what they’re learning.

“Their ability to talk to others, shaking hands, making eye contact, all those things,” have improved, adds Foster.

She points out that the Industry 4.0 class serves both students who want to start working right after high school graduation as well as those who want to earn a college degree.

MORE TO COME

And the district plans to offer even more industry-ready skills for its students.

In late September, the state awarded Brookfield a $1.4 million Career Technical Education Equipment grant. It’s the largest grant awarded to a Mahoning Valley school or district in the latest round of funding.

“The CTE equipment grant will allow us to create another pathway to graduation in engineering and science technologies,” Gibson says.

The district hasn’t yet narrowed down the industry recognized credentials that it plans to offer. “In general, right now we’re thinking about expanding our robotics to FANUC,” he adds, referring to robotics and automation systems.

Brayden Sangregorio, a senior, is taking the course for the second time, focusing on robotics because he enjoys it. He’s not sure, however, about a career path.

“I just think it’s pretty sweet how you can program it to do different things,” he says.

Brandon Hardman didn’t initially sign up for the class. It showed up on his schedule.

“But I kind of enjoy it now,” the senior says, adding that he likes working with mechanical equipment.

Brandon plans to attend trade school after graduation for either plumbing or carpentry.

Chu, the instructor, says before the course was added, many students had no idea what a career in manufacturing would be like.

“Most of the kids that come in here their first semester, they’re like, ‘Manufacturing doesn’t sound fun,’” she says.

They envision a dirty industry.

“It’s not that way anymore,” Chu says. “Things are automated. Things are clean. It’s not any kind of back-breaking work as long as you know a lot of those automated processes, which is what they’re learning in here.”

Now there’s a lot of interest among students in the class.

Although he enjoys the class, Ryland doesn’t plan to pursue a career in manufacturing, but he may use what he’s learning as a backup.

“I want to go into business administration but maybe at a robotics business – a little bit of both,” he says.

Pictured at top: Ryland Mihalcin and Bahr Martin kneel with a robotic dog inside their high school’s Industry 4.0 lab.