CANFIELD, Ohio – A robotic arm moves in a pattern across a table, based on programming by adult students in the TechCred program at the Mahoning County Career and Technical Center.

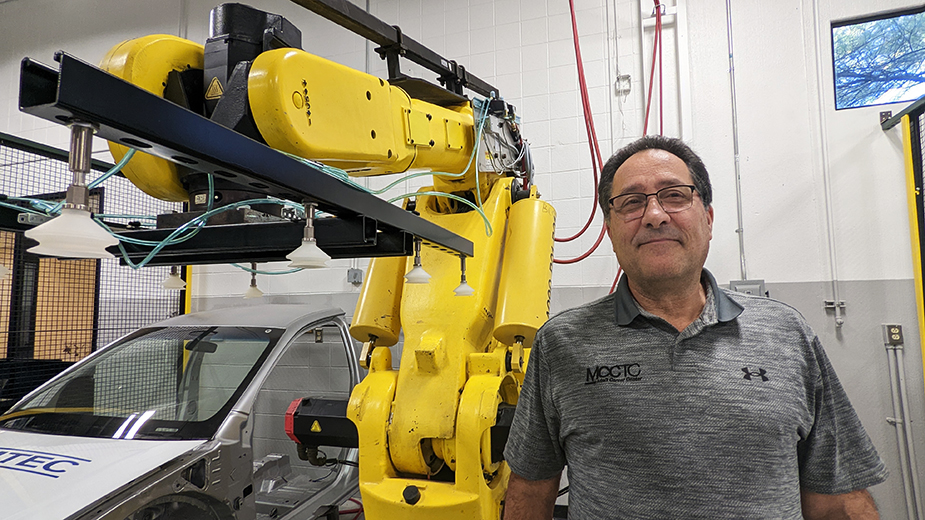

About 10 men gather around the moving machine with Tom Mihalopoulos, instructor for both the TechCred robotics and arc tool welding industrial programs at MCCTC. TechCred is a state program that trains and credentials manufacturing employees.

Mihalopoulos starts with the basics but says there is a lot of material to get through in the 36-hour robotics class – such as how to instruct the robotic arm’s movement to a precise location and when its handling tool gripper should open and close. By the end of the course, even those who came into the program with limited knowledge learn basic robotic programming.

“Hopefully, when they are out of here, their employers love them because they have a lot more knowledge,” Mihalopoulos says. “They don’t just operate the machines, they know a lot more about it.”

One of the men in the course is George Tacey, who started working as an electrician at a Youngstown mill years ago. He later worked at General Extrusions Inc. of Columbiana before the company was acquired by Pennex Aluminum in 2010.

Tacey worked a combined 16 years in maintenance specializing in programmable logic controllers. He believes in taking courses to gain new skills and stay on top of the changing manufacturing tools.

“You get left behind pretty quick if you don’t,” says Tacey.

Thomas Prosser has been at Pennex for five months. When he started, a manager told him the company wanted him to take the robotics class. He agrees with Tacey.

“Anything I can take, I’ll take it,” Prosser says, noting that the program looks good on a resume. “I’ve never messed with anything like this and it’s kind of new to me,” he says.

Prosser says he picks up on hands-on skills quickly, but knows there is a lot to learn.

“The more I learn, the more I know I don’t know,” says Mihalopoulos.

Although Mihalopoulos comes from a manufacturing background, he recently trained to teach the robotics program and loves it. He believes letting the students make mistakes here is the best way for them to learn and those who learn this trade can make a better living.

Pennex, Compco in Columbiana and Graphic Packaging Co. in Solon all sent employees to MCCTC for the robotics training class that started this fall. But they are not alone among the companies in the region with a growing reliance on the technology.

Robot sales hit a record high in North America in the second quarter with nearly 60% of those orders coming from the auto industry, says the Association for Advancing Automation.

With the return of the automotive industry to the region, as well as other manufacturers scrambling to find skilled employees, using robots for many manufacturing processes is here to stay.

“The robot can handle jobs that are boring, that are monotonous, that are dangerous, that are hot,” says James Jarvis, MCCTC employment and training coordinator. “The repetition just drives you crazy. It never gets COVID, never needs a sick day, never goes on vacation. There is no down time for a shift change. [It] doesn’t have to stop to use the bathroom. It doesn’t go have a lunch break. It works 24 hours a day, seven days a week if you need to.”

While some may be concerned that robotics is taking away jobs, Jarvis and Mihalopoulos understand that the manufacturing industry has embraced the technology and it will only continue to go in that direction.

“A lot of people think we’re taking away the labor, but it’s technology,” Mihalopoulos says. “You have to get out of the box. You have to move on. It’s not an easy thing for older people. But I’ve seen a lot of older people catch on, just like that.”

The instructors both point out increases in productivity because robotics leads to companies needing more people in other areas such as sales, marketing, shipping and receiving.

“I look at it this way: Robotics is the wave of the future,” Jarvis says. “Many companies are deeply embedded in robotics. So if you’re not involved with robotics, you’re going to wish you were in about 10 years.”

WAVE OF THE FUTURE

Automation has led to additional robotic-related jobs, as companies require employees capable of programming, maintaining and repairing the machines. While Mihalopoulos notes machines such as the robots in the lab can run for years, someone has to be ready when something goes wrong.

The employees with the specialized training obtainable through Tech-Cred and customized business and industry training programs at MCCTC will continue to be in demand.

In just six to eight weeks, the robotics-training program through MCCTC is helping employees train to hold jobs in automated manufacturing plants. Employers needing workers with these advanced skills can assist them in getting the required training through the program.

“They will be light years ahead,” says Jarvis, talking about the adults completing the program.

“I was a union sheet metal worker for 13 years,” he says. “When I go into different companies and look at how manufacturing fabrication is done, the stuff that I did is no longer done the way it was before. It’s automated or it’s done through technology or robots. I would be unemployable today with the skill set I had when I was 20 years old. They are light years ahead.”

Through his position at MCCTC, Jarvis is able to help area businesses tap into TechCred funding through the state of Ohio, up to $2,000 per employee for up to 15 employees per round for a total of up to $30,000. The next round of funding opens Nov. 1 and runs through Nov. 30. Provided they are from Ohio, employees can pay for the course up front and after they pass the tests for certification, the cost can be reimbursed.

TECH CRED OPTIONS

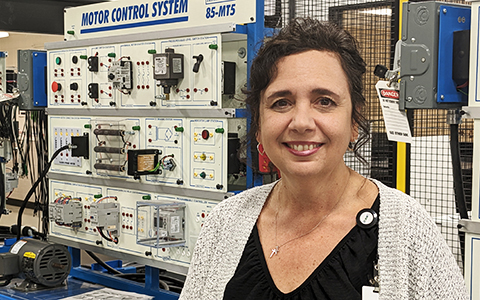

Robotics is not the only program at MCCTC where TechCred funding can be applied. Mary Mihalopoulos, supervisor of the adult career center, says the funding has been used for training for computer numeric controlled machining, medical phlebotomy certifications, State Tested Nursing Assistant for long-term health care, Society for Human Resource Management training and industrial pneumatics processes, Microsoft computer skills and American Welding Society certification. As long as it is a technology-based program, it can qualify for TechCred funding, she says.

The RAM-Tech lab, where MCCTC houses the robotics program, also has CNC mills and lathes, pneumatics machines, hydraulics and the robotics equipment, including a large robot arm, donated by Lordstown Motors Corp., which is capable of lifting a new windshield onto a car.

The school has participated in TechCred programs for nearly three years, with certificate courses starting every other month. Since the state started the program, both employers and employees have benefited.

“They’re encouraging companies, businesses and associations to use these dollars that are available so they can upscale their career, as well as their workforce, whether it be technology based or technology infused, or something that they are looking ahead to train their employees.”

MCCTC has Jarvis and another person on staff to assist those in the manufacturing and health care industries to find the courses they need for their employees. Some have come into the program through the Mahoning Valley Manufacturing Coalition.

“Truly, if we don’t have a curriculum, we try to bring people from industry and we develop a program,” says Mary Mihalopoulos, noting Ohio technical centers are nimble at creating customized training.

The program can be adjusted so an employer who only needs one or two employees trained can be matched with other companies needing the same amount of training.

MCCTC strives to keep the class sizes small, giving students more hands-on time and individual attention with instructors who actually work in the industry.

Pictured at top: Tom Mihalopoulos teaches the robotics and arc tool welding programs at the Mahoning County Career & Technical Center.