By Jeremy Lydic

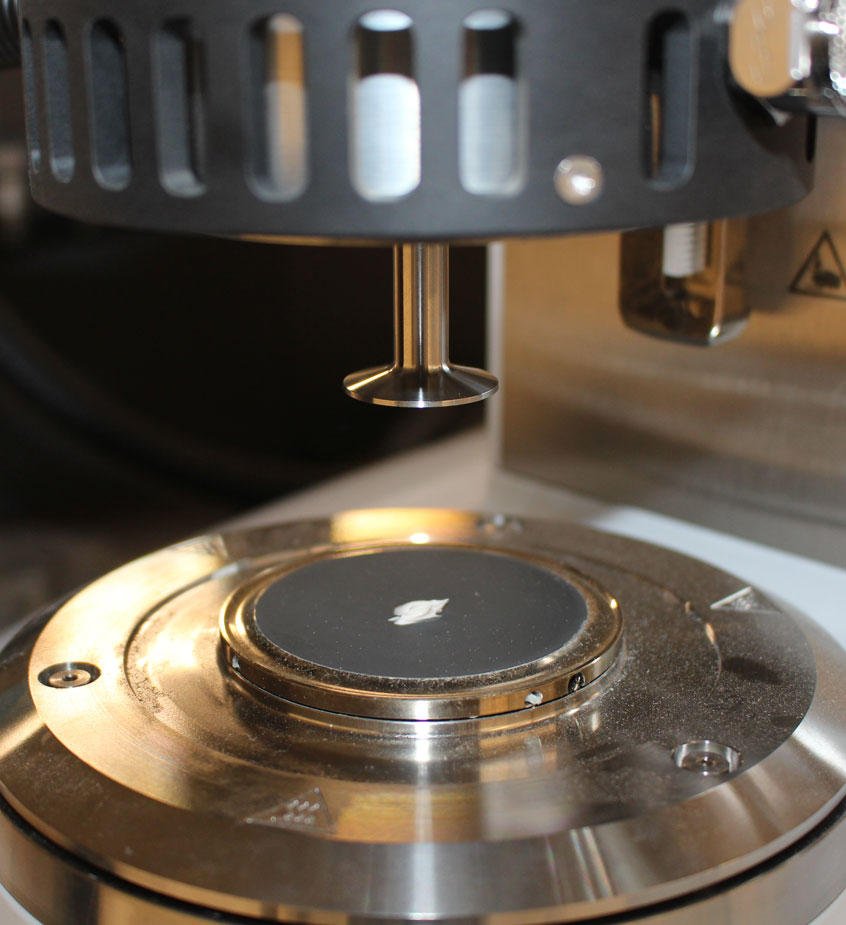

YOUNGSTOWN, Ohio — In a corner of the ground floor inside the Youngstown Business Incubator’s Tech Block Building 5 downtown, Gary Gladysz uses a rheometer to test a small sample of a white, pasty substance.

The substance is an initial formulation of his 3D printer ink. A small dab sits on a plate attached to the device, which uses a cylinder to press down and twist the ink, measuring how much torque is required to manipulate the ink. This measures its viscosity, Gladysz says.

“Since we’re not curing on the part bed, we need a real thick paste so when you put layer upon layer it doesn’t collapse,” he says. “You want as viscous as possible. But when you’re pumping it, you want that viscosity to drop.”

Unlike traditional thermoplastic 3D printing filament, which requires a heated print head and print bed to cure the part as it prints, Gladysz’s thermosetting ink is cured in an oven. This allows printing to take place anywhere in ambient conditions, he says.

However, the ink must be thick enough to hold its shape until it’s time to be put in the oven. Gladysz’s inks are designed for shear thinning, in which the viscosity of the liquid decreases under shear strain. So the ink’s viscosity reduces when pumped through the print head, then increases again once the bead is laid on the part bed, he explains.

He is also testing inks to determine how many layers can be stacked before the uncured part starts to collapse on the part bed, he says. Thus far, Gladysz has successfully printed a part that is 40 layers thick, he says.

“I could have done more, but that’s what the print called for,” he says. The part cured in the oven after two hours, he says.

Testing is the first step in taking the inks to market through his startup, X-Link 3D – formerly En Masse Additive. Gladysz had been working with the YBI and its portfolio company Juggerbot 3D to develop the inks and, eventually, take them to market.

A Brookfield native, Gladysz left the Youngstown area 20 years ago to pursue a career in chemical engineering and materials science. For the time being, he doesn’t intend to move his family from their home in Massachusetts, but says the additive manufacturing environment in Youngstown created a new entrepreneurship opportunity here.

Gladysz already has some of the characteristics outlined for the first four X-Link products, he says, including a low-cost version with an operating capability of about 150 degrees Celsius. For the initial rollout, he chose raw materials that presented the least amount of risk, but come at the highest price, he says. He’s working with Juggerbot to identify the potential end users that cover the largest share of the market.

“I’m trying to bring that price point down a little bit while still trying to optimize some of the mechanical and physical properties of the inks that the market would respond favorably to,” he says.

While he’d eventually like to sell his inks to industries like aerospace, Juggerbot’s customer base has a more varied number of requirements, “so I have more input,” he says.

Initially, he planned to target 3D printing service bureaus, which provide printing services to companies who outsource additive manufacturing work rather than doing it in house. But service bureaus require “turnkey” systems before they can offer the services to their customers, he says.

“It would take years to develop all of the data set that they need in order to say, ‘Ok. We’ll work with it,’ ” Gladysz says. “[Juggerbot] have totally changed my focus of where my first customers will be on the small scale.”

There’s still a lot of work left to do to get the inks where service bureaus need them to be, he says, so Gladysz and Juggerbot are eyeing first adopters that like to be on the cutting-edge of technology.

Some of those early adopters include universities with research capabilities, like Youngstown State University, Kent State University and the University of Akron, among others, says Zac DiVencenzo, president of Juggerbot 3D. However, Juggerbot’s customer base includes commercial entities who can invest in the cost of using the material to get out ahead of their competitors without the benefit of grants, he says.

“It’s going to be all hands on deck because the project costs money,” he says. “Having commercial partners drives it faster. You’re going to have someone who can see the technology for its value and they’re going to want to legitimately incorporate it because there’s a significant impact.”

Working with commercial partners is more than just supplying them with materials, parts and machines, DiVencenzo says. The goal is to help them adopt it as fast as they can, he says, which can also lead to getting first-hand testimonials from them.

“You need people to be excited about what they just saw and you need them to speak for you. That’s going to make or break new technology,” he says.

Those testimonials can go toward writing white papers that document the effectiveness of the inks, which will allow Gladysz to market the products to other industries and end users, he says. Gladysz expects he needs about three more weeks of testing at YBI before he has a formulation for his inks that he can take to the early adopters, he says.

Already he expects the inks to be attractive to end users. Because they can be used in ambient conditions, the process is 400% more energy efficient than a traditional 3D printing process, Gladysz says, making for a less expensive product. High-performance thermoplastic filament can cost around $200 per pound, he says.

“We’re going to be less than $100 per pound,” he says.

The inks are designed to be printer and format-agnostic, regardless of printer size, he says. The trade off, he says, is the upfront cost of the curing ovens and retrofitting any existing equipment to work with the inks.

“I want to retrofit printers that are already out there to run these materials,” he says.

Retrofitting industrial printers to use the materials would take no more than six weeks, DiVencenzo estimates, and would require additional training. The retrofit itself could cost anywhere from $10,000 to $25,000, he says.

Juggerbot is working to develop a standard system to allow its own printers to use the ink for industrial print jobs, DiVencenzo says. Though much of the industry is growing toward pellet extrusion printing, there is growing interest in two-part epoxy materials, he says.

For the last six months, Juggerbot has been working with Chromatic 3D Materials, Minnesota, to design a printer that uses thermoplastic filament as well as two-part polyurethane thermoset materials, DiVencenzo says. Last year, they sold a printer to Chromatic 3D that had print heads for both thermoplastic and thermoset materials.

When Gladysz approached them about using their system to print with his inks, “we had high confidence that we could work with the materials, but we weren’t certain,” DiVencenzo says. The material from Chromatic 3D was more like a liquid, he says.

“This technology that we have in our office was just here for us to develop,” he says. “It’s completely different to print an epoxy, so we were a little nervous. And the material is really thick; it’s almost like printing clay.”

But the process worked and they were able to print a part in 20 or 30 minutes, he says. The hardware and electrical components inside of the printers “seem to be doing everything they need to do to process the material,” but Juggerbot will need to develop a custom program to dictate precisely how the material can be used while ensuring faster printing and with more repeatability, he says.

It took Juggerbot about two days to write the initial program that printed a part on a three-foot-by-three-foot bed, he says. The company will continue developing the program to move on to bigger print, including functional parts.

“It’s a wonderful material to work with and we’re excited to take the next step with Gary,” DiVencenzo says. “We see a lot of value with Gary locating his startup here in Youngstown.”

Related story:

Jan. 10, 2020: Startup to Make 3D Printing Inks ‘En Masse’