Auto Techs Go From Greasy Hands to Hands-on Computers

YOUNGSTOWN, Ohio – When Alex Charnesky started as a service technician at Sweeney Chevrolet in Boardman four years ago, the job wasn’t precisely what he was expecting, he says.

“It’s definitely not what people think it is,” Charnesky says. “I know myself, I imagined a lot more changing pistons, changing engines. That kind of thing. But it’s a lot more of a cleaner job anymore.”

Charnesky’s day-to-day includes more work on computers than he was expecting. Having grown up working on his father’s classic cars, including a 1968 Camaro and 1965 Chevelle, he had a good grasp on the basics of auto work.

But since graduating from the auto tech program at Mahoning County Career and Technical Center and beginning his career at Sweeney, he says auto techs need to be more familiar with technology now than perhaps 20 or 30 years ago.

“You have to understand what this module does, and how that module talks to this module, and why they talk to each other and how they make the vehicle run,” he says.

The revelation was a surprise to Ja’Mya Agee as well. Agee, 10, and her sister, Ja’Nese Agee-Wingo, 9, heard from Charnesky and other auto techs during the Brain Gain Navigators event featuring Sweeney and MCCTC. The virtual tour on Feb. 17 provided students a snapshot of an auto tech career.

Presenters were Nick Deniakis, shop foreman at Sweeney Chevrolet, and John Zehentbauer, MCCTC superintendent.

Middle and high school students who logged on asked them questions about the profession, including what training and education is needed, what daily work entails, what jobs are available and how much they pay.

Becoming an auto tech crossed Agee’s mind once or twice, she says. The idea of learning how to work on cars “is cool,” she says, because “it’s like doing a puzzle.” But using a computer to diagnose and even fix some of the problems on cars was something she didn’t expect.

“It caught me off guard,” Agee says. “I never thought you would use a computer for working on a car.”

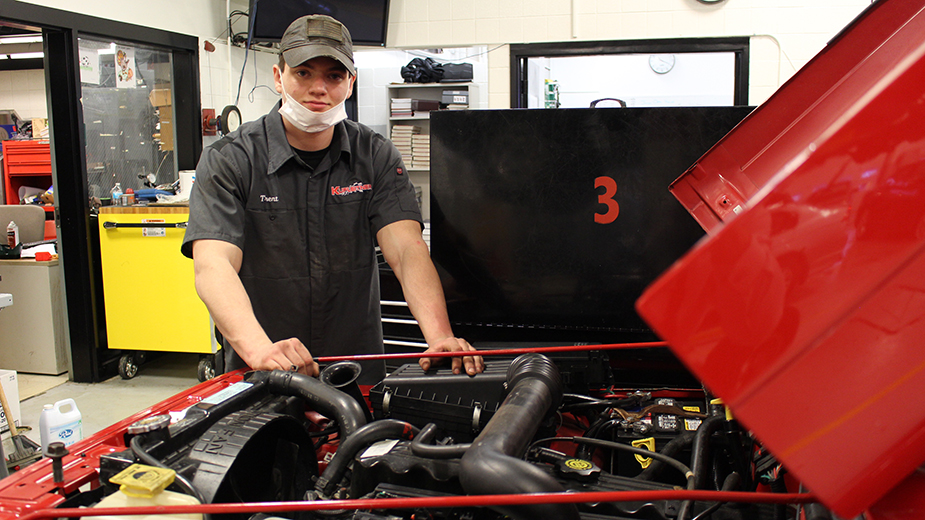

That doesn’t mean, however, that auto techs don’t get a little greasy from time to time, notes Nick Deniakis, shop foreman at Sweeney Chevrolet. It’s still a hands-on job, which is ideal for students who prefer working with their hands and learning how to take things apart and put them back together, he says.

Still, working with computers and making software updates to vehicles make up a big part of an auto tech’s 40- to 50-hour work week.

That opens the door for students interested in computers, software and even video games to consider the career, he says.

“There’s a lot of times where you could spend a whole day just doing software reprogramming on several different modules and several different vehicles,” Deniakis says.

The reality of the work continues to inform the education and training students receive at MCCTC, says Superintendent John Zehentbauer. While the school primarily focuses on the basics of auto tech work, Zehentbauer says the school is always working to implement the latest technology into its curriculum.

“Especially auto tech and our automotive programs, we look at anywhere from 10% to 20% of our programs to be emerging technology,” he says. “We’ve been keeping a close eye on what’s happening at Lordstown with the electric vehicles.”

Understanding electronics, including motor controls and battery systems, are going to be “a huge part” of working in the emerging electric vehicle industry, he says. Partnerships with Eastern Gateway Community College and Stark State College, as well as area dealerships, are helping to guide MCCTC “in the right direction on up and coming technologies,” Zehentbauer says.

EVs will drive increased demand for auto techs in the area, Deniakis adds, particularly as companies like General Motors introduce more EVs in their lineup. However, techs will still need to know how to work on typical gas-fueled vehicles.

In addition to technical computer skills, MCCTC trains 11th and 12th-grade students in its auto tech program in diagnostics, repairs, brakes, steering, suspension, preventive maintenance and engine work, says Principal Matt Campbell. They learn shop safety and how to properly use tools and hydraulic lifts. The school also has an adult program.

Students learn academics as well, with math, science and English teachers physically getting into the auto tech lab with instructor Marc Silvestri to learn how to apply lessons to what the students learn in the lab.

“All of our academic work, it goes off of our motors and what we do in labs,” says Jonathon Figley, a senior at Struthers High School who is enrolled in the MCCTC auto tech program. “So it all ties together and works out perfectly.”

Auto tech students need to have a good understanding of math and science, “more so math now that we’re moving toward electric vehicles,” says Sweeney’s Charnesky.

Traditionally, science plays the most important role, he notes, because techs need to be able to work with ratios, measure how much air is flowing into the engine and gauge sensor readings.

MCCTC’s Zehentbauer advised middle school students attending the virtual tour presentation to get started now. Career centers like MCCTC and the adjoining Valley STEM+ME2 Academy offer annual summer camps for students interested in exploring career paths.

“There’s a variety of sources that give kids camps and experiences with mechanical things and working on vehicles,” he says. “From there, look toward a STEM school. It’s a very good place to kind of create your own path.”

Area dealerships are “heavily involved” in hiring MCCTC graduates, says Zehentbauer, who guarantees students will have “not only one, but several job offers” from local dealerships.

“We basically take students from A to Z,” he says. “Some students haven’t even used a screwdriver before.”

Once employed, techs are always learning, adds Sweeney’s Deniakis. New employees start as a quick lube technician. The ones who show the aptitude and initiative to move forward are enrolled in the GM Automotive Service Educational Program, or ASEP, at Stark State College.

The two-year ASEP program is offered to Sweeney employees for free, and trains technicians to earn eight certifications, as well as on the job training with a master tech. After the two years, graduates get their own workstation and can work their way up to being a master tech, Deniakis says.

Master tech fields include anything from engine repair to engine performance, automatic transmission and more, he says. Some techs can achieve master tech status in a few years, while others take several years.

Drake Pondillo, a tech at Sweeney, just achieved master tech status at the age of 24. “That is a great achievement at such a young age, because he worked really, really hard to achieve that goal,” Deniakis says.

Pondillo is an MCCTC graduate who’s been at Sweeney for five years. In high school, he says he never thought he would pursue a career as a master tech, and he credits MCCTC for giving him the opportunity to follow that path.

“Everything was like a stepping stone to becoming a master technician,” he says. “If you like working with your hands, it’s a good opportunity.”

Salaries for auto techs are based on their skill set, Deniakis notes. Entry level techs start anywhere from $10 to $14 hourly, while the more seasoned technicians can earn $20- to $25 hourly.

“So you take that and then incorporate the flat rate system, which is based off of each job, what it pays, you can make a very good living,” he says.

And the work is enjoyable, Deniakis says. With 17 years of professional experience, the career still provides opportunities to learn new things and overcome new challenges, he says.

“And then you come up with a solution and get that car rolling again, for the customer. It’s just a great feeling to know that you did that. And that’s something that excites me,” Deniakis says. “Knowing that you got that customer going and got that family back on the road, maybe for a vacation trip or somebody in transit that broke down. It’s just a great feeling to be able to help them.”

Copyright 2024 The Business Journal, Youngstown, Ohio.