Axion Power Enters New Era as R&D Company

NEW CASTLE, Pa. — Much of the sprawling, nearly 70,000-square-foot production area of Axion Power Inc.’s plant is dark. The hulks of machinery that once produced 600,000 lead acid batteries a year sit mothballed.

Toward the rear of the plant in New Castle, Pa., is a smaller enclosed area – 7,000 square feet or so – flooded with light. There, a line of small robotic arms stand at attention but inactive for the moment. When operational, this automated process manufactures a small carbon electrode pack that Axion executives say sets the course for the future of their company.

“In 2016, we made our last lead battery here,” says Richard Bogan, CEO and president. “We’re in the process of moving the entire production operation to China.”

In many ways, Axion Power reflects the harsh realities staring down American manufacturing today. Old methods of production can no longer compete with the highly automated systems used overseas that, at a far lower cost, turn out products such as the lead acid batteries used in vehicles or as power backups.

At the same time, Axion hasn’t thrown in the towel, Bogan says, as the company makes the transition from a major manufacturing operation to a research and development-based business.

“We’ve morphed into an R&D technology company,” Bogan affirms, acknowledging that the shift from large-scale manufacturing to a company devoted to developing and improving technology came with costs. Last year, about 70 were employed at the New Castle factory. Today there are fewer than 10. “We’re actually a startup,” the CEO declares.

Since last year, Axion has worked to rebuild its business from scratch – no longer relying on the sale of lead acid batteries. Instead, Axion is focused on developing and licensing its technology and collecting royalties from these new products.

The core of the business – the “secret sauce” as Bogan calls it – is proprietary technology that replaces the negative lead plate in the battery with a carbon electrode pack.

“We make a component to the lead acid battery that changes its characteristic in a significant, more favorable way,” he explains.

The improvement allows the battery to operate more effectively on a partial charge, adds plant manager Joe Cole. Some automotive manufacturers, for example, have introduced vehicles equipped with technology that enables the battery to shut down the engine automatically at stoplights, allowing for improved fuel economy.

When the engine stops, it places an additional strain on a standard lead acid battery and the vehicles end up operating on a partial charge.

Over time, this causes the negative plate to sulfate and reduce the battery’s power, eventually disabling the automatic start-stop technology on a traditional battery.

Replacing the negatively charged plate with a carbon electrode pack removes the failure mechanism in the battery and extends its life tenfold, Cole says. “This technology works very well on a 50% charge,” he says. “Stop-start vehicles are very good for this.”

Cole has worked at the plant since 1989, when it was under the ownership of New Castle Battery Inc. At one time, the company produced 600,000 lead acid batteries a year and employed about 150.

When it suffered financial difficulties in 2006, New Castle Battery placed the plant and assets up for auction. Axion – formed in Toronto that year – stepped in and acquired the plant and equipment. It maintained production while starting to develop this technology.

Axion’s carbon electrode pack is manufactured in New Castle and already the company is in the process of developing a fourth and fifth generation of this technology that should appeal to the commercial market.

The highly competitive nature in the battery manufacturing business made it impossible to continue producing lead acid batteries at the New Castle plant, Cole notes.

Even some of the more modern plants newly built in the United States found it difficult to go head-to-head with their highly automated counterparts in Asia, he adds.

“We used to build Turbo Start, 16-volt racing batteries,” adds Doug Speece, Axion’s sales and marketing specialist. “We built our own systems around that technology and now we’re moving away from that, and looking for somebody else to build the products.”

That’s led to the company to seek new investors and partners in Axion, Bogan says.

A breakthrough occurred late last year when Axion announced it had signed a letter of intent to license its technology to Fengfen Co. Ltd., based in Baoding, China.

Under the proposed agreement, Fengfen would have the exclusive rights to sell Axion’s battery technology in China, Macau, Hong Kong and Taiwan, and non-exclusive rights to sell in North America.

“They are the largest lead acid battery manufacturer in the People’s Republic of China,” Bogan says. “Now we’re looking for a long-term licensing agreement with them.”

The letter of intent calls for $5 million in cash to be paid to Axion over two years, Bogan says.

“Once we sign the agreement, the company will receive $900,000 per quarter for the first year and the $250,000 per quarter during the second year,” he says.

The agreement would also include 2% in royalties based on sales in China and North America, with a guaranteed minimum of $1 million annually.

“They’ll be the first to take this application commercial,” Bogan says. The company also is interested in using Axion’s technology to produce batteries for Class 8 trucks in the United States.

The carbon packs would be manufactured in New Castle and sent to China, where they would be installed in the batteries as they’re manufactured.

Once manufactured, the batteries would be sold to users in Fengfen’s markets. In the case of a Class 8 truck customer, those batteries would be shipped back to the United States, Bogan says.

The next step is to secure similar exclusive deals with companies in Europe and Latin America.

“The Chinese have looked at what we’ve gone through and they see the opportunities,” Bogan says. “We’re going to enhance that R&D work. That’s the initiative.”

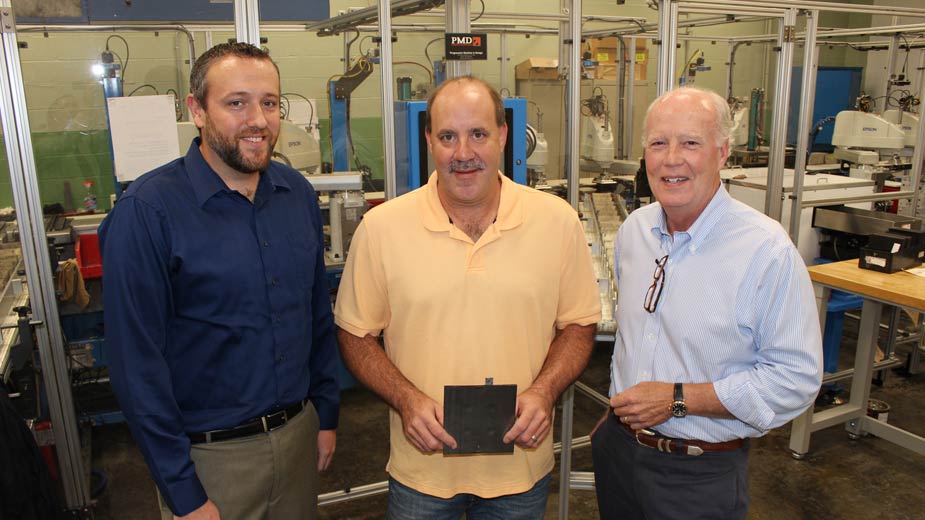

Pictured at top: Axion Power’s Doug Speece, Joe Cole and CEO Richard Bogan say the company has been revamped and is “actually a startup.”

Copyright 2024 The Business Journal, Youngstown, Ohio.