BDI Acquires New 3D Printer from JuggerBot

YOUNGSTOWN, Ohio – An industrial 3D printer made by JuggerBot 3D will allow a global manufacturer and distributor of industrial products to expand its capabilities.

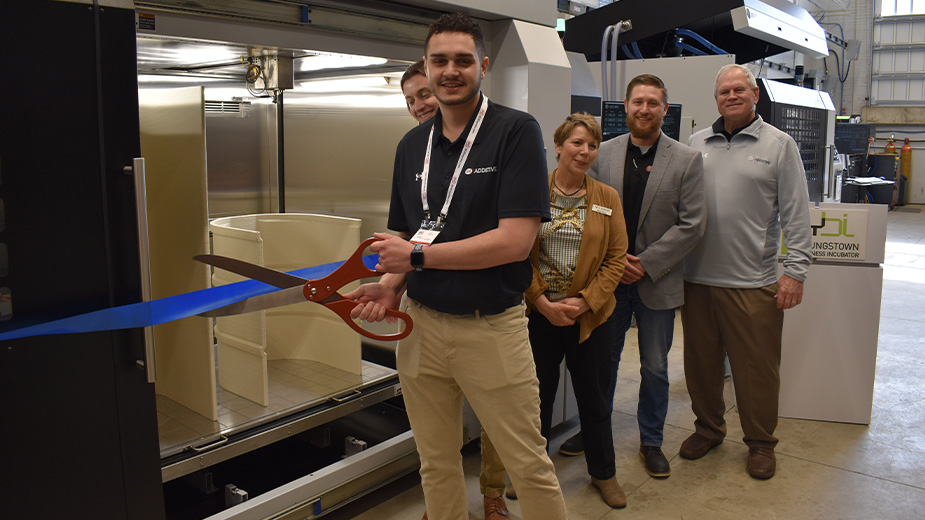

Representatives of the Youngstown Business Incubator, JuggerBot 3D and Cleveland-based BDI USA participated in a ribbon-cutting Thursday morning for the Tradesman Series P3-44 industrial 3D printer that BDI purchased from JuggerBot.

The machine is the latest industrial 3D printer that BDI has purchased from JuggerBot, which launched about nine years ago and is based in YBI’s Tech Block Building #5.

“We’ve been working on this for quite some time,” Zac DiVencenzo, president and co-founder of JuggerBot 3D, said. “It’s a new, modern tool for the modern tradesperson.”

The printer uses “one of the newest technologies out in the market today to process thermoplastics at very high volumes and rates to really take the production of additive manufacturing to a new level,” DiVencenzo said. With a build volume of 3 feet by 4 feet by 4 feet, it can be used for rapid prototyping, but is intended for production.

The printer uses fused granular fabrication – or pellet-fed – technology, rather than fused filament fabrication. It is the second-pellet-fed unit BDI has purchased from JuggerBot.

“We’re one of only a handful in North America that produces the technology,” DiVencenzo said. “We’ve been doing this now for three years, so we’re a little bit ahead of the curve. … We’re continuously putting Youngstown on the map.”

“We’ve got the opportunity to completely change how distribution works,” said BDI USA’s president, John Ruth. BDI has several customers that “additive really fits well for,” including large companies such as General Motors, General Mills, Kraft and Kellogg that run old equipment utilizing parts “so obsolete” that replacements aren’t easily obtainable and have to be bought in such large quantities that it isn’t practical.

“We’ve started to print replacement parts, and it works really well,” Ruth said. “It saves the customer money, reduces lead time and it drives revenue for us, but, more importantly, it makes our customers’ success easier.”

Acquisition of the printer represents “a major step forward in our mission to provide our customers with the best possible solutions,” added Austen Meredith, parts replication manager for BDI.

“I’ve seen the other side of this, where I’ve worked for companies and we’ve struggled to get parts, whether it’s long lead times or supply chain issues,” Meredith said. “It’s really awesome to be on the other side where we’re actually making those parts and helping customers with those issues.”

Thursday’s event provided “an incredible opportunity to showcase the relationship” between JuggerBot 3D, a YBI startup, and BDI, said Barb Ewing, YBI CEO, said.

“This is truly validation that we have an ecosystem here locally that can create world-class additive manufacturing products that are second to none, that nobody else in the industry can recreate,” she said. “And that this really is becoming the epicenter for additive manufacturing in northeast Ohio.”

Ruth would only say the new printer cost “a lot” when asked about the price tag.

“You could buy multiple really nice cars for what one of these machines costs, but it’s an investment in the future,” he said. “It’ll take us a few years to realize return on the investment. But we have to start, and that’s what we’re doing.”

“We’re just blessed to have this opportunity to work in a community with additive [manufacturing] such a big part of it,” DiVencenzo said.

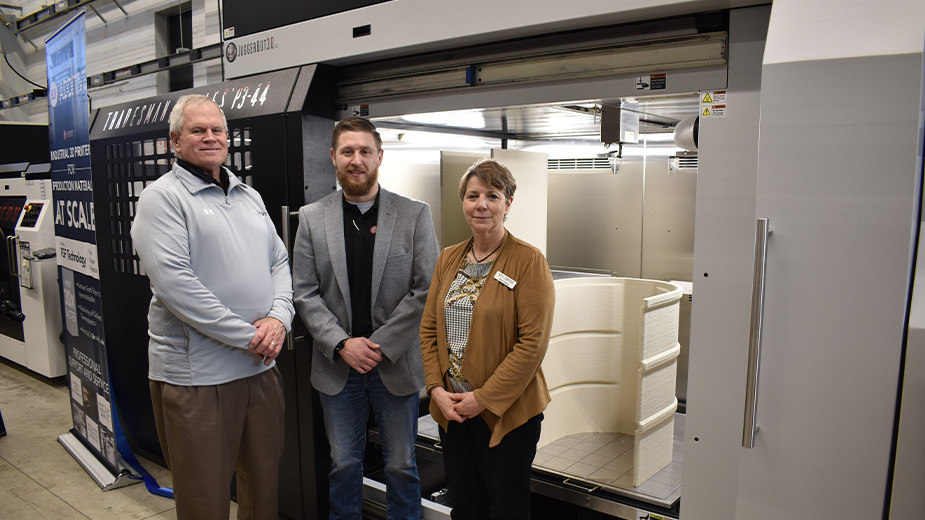

Pictured at top: From left, John Ruth, president of BDI, Zac DiVencenzo, co-founder and president of JuggerBot 3D, and Barb Ewing, CEO of the Youngstown Business Incubator.

Copyright 2024 The Business Journal, Youngstown, Ohio.