Big and Small, Manufacturing Drives Valley’s Innovations

YOUNGSTOWN, Ohio – The process of producing seamless steel piping has been pretty much perfected, Vallourec Star President Judson Wallace said, but advanced manufacturing will still have a role in the mill’s future. Not in the steel itself, but in the tools used to produce it.

“When people come to our mill, they’re surprised by how few people there are on the shop floor,” he said. “The people on the floor are engineers and technicians. If everybody’s out there, we have a problem.”

He was among the speakers at a series of panel discussions Thursday at Youngstown State University hosted by the Washington Examiner, “Examining Youngstown: Innovation Through Advanced Manufacturing.”

The future of manufacturing at Vallourec Star, Wallace continued, is in advanced machines that can improve the plant’s quality and efficiency. And to accommodate those machines, more investment in the $1.5 billion mill on U.S. Route 422 could be in the works.

“There’s nothing on the drawing board to do that, but at some point in the future we’ll have to replace it. Capital equipment to build pipe mills is very expensive, so this new mill in the future will be a significant investment,” he said. “Sometime in the next five to six years, we’ll have to do something and either upgrade our current mill or build a new one. Our current mill is at capacity. We can’t produce any more steel, so to produce more we’ll have to build new.”

Advanced manufacturing, whether it be high-tech machines or additive manufacturing, isn’t just limited to large, international companies like Valloruec. Youngstown State University operates a lab with machines covering the spectrum of 3D printing methods. Through internships and partnerships, students have plenty of opportunities to get hands-on experience before graduation. Portfolio companies at the Youngstown Business Incubator, Freshmade 3D and Juggerbot 3D, are developing new additive manufacturing materials and machines. The incubator also works with area companies – about 85 in the past 18 months – to see how they may be able to integrate additive manufacturing into its processes.

“We’ve seen projects that range from a low impact of $5,000 to $10,000 and we’ve seen improvements on the books of over $100,000,” said Stephanie Gaffney, director of additive manufacturing programs at the YBI. “Precision, low-volume tooling is where we think the easiest place for companies to adopt is.”

While there has been concern over the loss of jobs from the installation of advanced manufacturing machines, she said that oftentimes, Mahoning Valley companies that adopt the technologies aren’t displacing workers.

“Manufacturers aren’t looking to replace, they’re looking to enhance current employees with additional training to move them into other operations within the company,” she said. “They’ll go get continuing education and learn new processes so they can be part of the team.”

The willingness to adapt to new methods and workplace demands, many panelists agreed, has long been a hallmark of the Valley, stemming from the generations of steelworkers. Wallace pointed to previous shift cuts at Vallourec Star, when the plant operated a single, midnight shift.

“When you’re running a 24/7 operation and asking people to work different hours or weekends or staying after the end of their turn, they do that,” he said, noting the decision to build the mill in Youngstown was influenced in part by the area’s work ethic.

Participating in the panels were Wallace, YSU President Jim Tressel, YBI CEO Barb Ewing and America Makes Executive Director Rob Gorham speaking on the area’s partnership and advancements; Gaffney, YSU professor Brett Conner, Juggerbot chief operating officer Zac DiVincenzo and Vallourec Star’s Pat Kiraly on the details of additive manufacturing and its impact on the region; and Youngstown/Warren Regional Chamber chief operating officer Sarah Boyarko, former state senator Capri Cafaro, Eastgate Regional Council of Governments’ economic development program manager Sara Daugherty and Grow America’s Infrastructure Now CEO Brigham McCown on infrastructure and economic development.

Regionally, the arrival of America Makes in 2012 brought with it a turn to advanced manufacturing as a focus, as the YBI changed from primarily working with business-to-business software developers to companies in the 3D printing field and YSU started setting up its laboratories. The collective change has led to the creation of partnerships throughout the area, said America Makes’ Gorham, which are crucial to its total economic development.

“The ecosystem we’re creating is unique. When I travel across the country, you don’t have the sense of community. You never hear the YBI talk about themselves without having YSU or America Makes in the conversation,” he said. “We don’t consider ourselves a standalone entity trying to bring manufacturing back to the area. We’re part of this broader thing that’s happening.”

The work has spurred the area’s industrial sector as a whole, which in turn has boosted the region’s economy. Six of the seven projects the Youngstown/Warren Regional Chamber is working in within Youngstown city limits are in the industrial sector, reported Boyarko, and the chamber has $2.2 billion in pending projects, including local expansions and new arrivals. Ewing said the YBI is in talks with two companies from southern California to relocate here because of its renown in the 3D printing sector.

“People don’t understand outside of Youngstown the aspirational quality about this community and the new industry that’s growing here,” said Salena Zito, the Washington Examiner national political reporter who moderated the discussions. “It was important to talk about this and not only how it’s impacting the economy and infrastructure and the school, but also how it’s bringing national economic and academic attention.”

Zito has made several trips to Youngstown since the previous presidential campaign cycle. Among her works is “The Great Revolt: Inside the Populist Coalition Reshaping American Politics” and a series of columns for the New York Post detailing voters in Ohio and Pennsylvania, which won her an award from the Associated Press.

Much of the advancements, she and the panelists noted, start locally, rather than by decisions made in Washington, D.C.

“National leaders have the ability to provide funds, but you don’t want them to manage the outcome. You want the outcome to come from local leaders like the [Youngstown] Business Incubator and business owners and mayors,” Zito said. “It comes from the bottom up in how it’s distributed and how it makes the town and community better.”

Going forward, one of the largest challenges facing overall economic development in the Mahoning Valley is infrastructure. As an example, former Ohio state senator Capri Cafaro pointed to efforts during her tenure to better connect Lake Erie and the Ohio River via improved roads and railways between Ashtabula and Wellsville, which never came to fruition as the Great Recession halted such discussions.

Elsewhere, the region’s roadways aren’t always properly designed to handle today’s logistics needs. Among the recent projects to address the problem has been the widening of Interstate 80, a $91.5 million project announced in 2015.

“We were built for industry, so we have some great infrastructure. In some ways, we were built out of it,” said Eastgate’s Daugherty. “Trucking is supposed to grow by more 67% in the next 10 years. It comes down to freight and having access to sites through two-lane highways.”

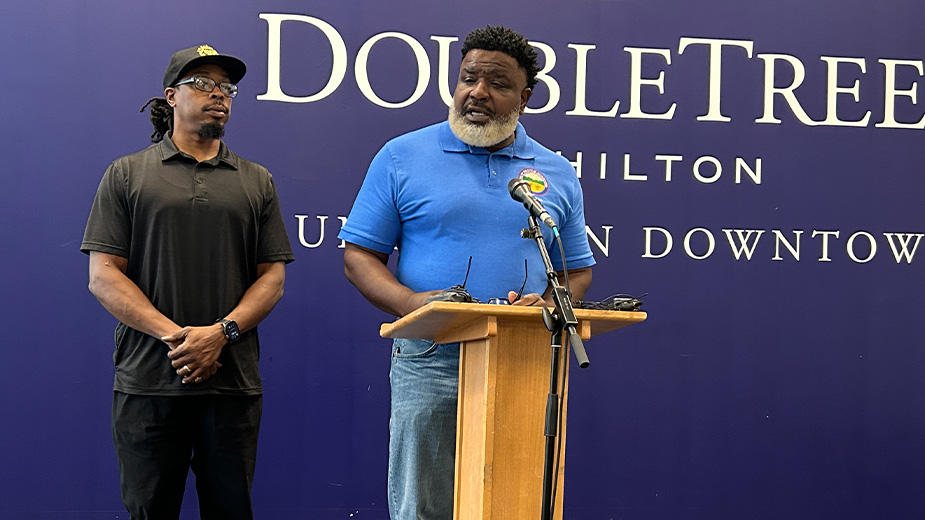

Pictured: Vallourec Star President Judson Wallace, YSU President Jim Tressel, Washington Examiner reporter Salena Zito, America Makes Executive Director Rob Gorham and Youngstown Business Incubator CEO Barb Ewing take part in a panel discussion on manufacturing at YSU Thursday.

Copyright 2024 The Business Journal, Youngstown, Ohio.