Ohio Manufacturers to Make up to 1M Face Shields

Updated April 9, 4:10 p.m.: Information and quotes from Ohio Manufacturing Alliance

YOUNGSTOWN, Ohio — In his daily briefing, Gov. Mike DeWine announced that 19 manufacturers associated with the Ohio Manufacturing Alliance will produce and deliver 750,000 to 1 million face shields over the next five weeks.

The alliance worked with three hospital groups, which provided the specifications for the prototype developed by the Manufacturing Advocacy & Growth Network, or MAGNET, DeWine said. The alliance “went from prototype to development in two weeks,” he said.

“Pulling together a complex supply chain often takes nine months to a year or longer, but through the commitment of these Ohio manufacturers, we have done it in about a week,” Ethan Karp, president and CEO of MAGNET, said in a press release.

Supply chain partners were identified from the RepurposingProject.com website, which was introduced on April 1. Partners including die cutters, injection molders, elastic-band cutters, plastic suppliers and assemblers. JobsOhio helped secure the raw materials.

“These are companies that normally make products ranging from toys to engine parts,” DeWine said. “These are true partnerships. Ohioans coming together, working together to find a solution.”

Eric Burkland, president of the Ohio Manufacturers’ Association, credited the state’s “deep industrial base” and “embedded know-how” for creating the ability for manufacturers to retool their operations to meet the personal protective equipment needs of the state.

“The innovation and responsiveness of our manufacturers – and their supply chains – are bearing fruit immediately and will be critical to the recovery of the state.” Burkland said in the release.

The final assembly will be made at Little Tikes, Hudson, which produces plastic toys.

“Little Tikes is proud to play a key role in this joint effort to drive the development of more than 750,000 face shields, one of the most urgently needed PPE items for hospitals across the country,” said Isaac Larian, CEO and founder of MGA Entertainment, which owns Little Tikes. “Ensuring these supplies are distributed to the brave men and women who are fighting for us, is essential to stopping the spread of COVID-19.”

The full list of companies involved in the face shield project can be found here.

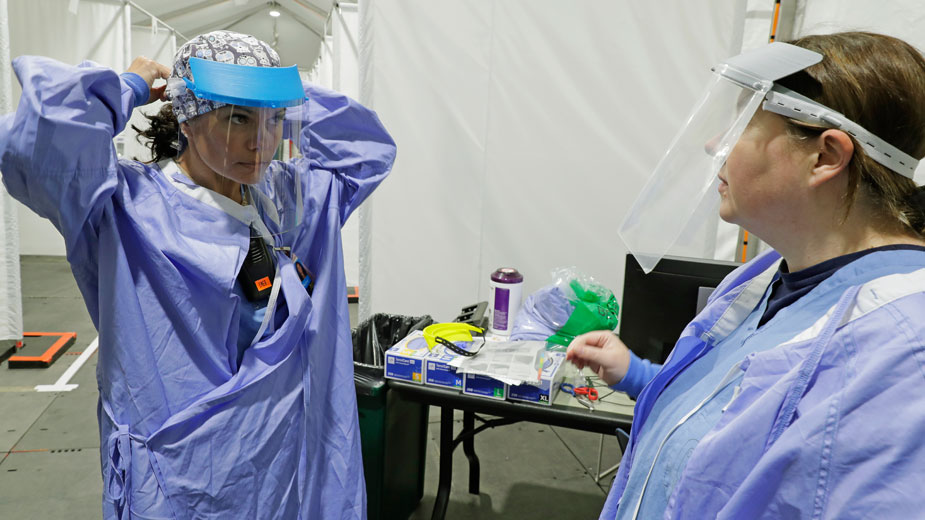

Face shields are an element of PPE used by health care providers, first responders and nursing home employees during the coronavirus pandemic.

The face shields can be sterilized at the hospitals and reused, DeWine said. When assembled, they will be sent to the Ohio Department of Health and distributed across the state.

“The purpose is not for us to hold them. The purpose is for us to get them out. And we intend to do that,” DeWine said.

Pictured: In this AP photo, emergency services nurses at Harborview Medical Center in Seattle, demonstrate how they wear medical face shields that were 3D printed and assembled by members of a network of volunteers using a design approved and hosted by the U.S. National Institutes of Health. (AP Photo/Ted S. Warren)

Copyright 2024 The Business Journal, Youngstown, Ohio.