Center Street Technologies Positions Valley for Future

YOUNGSTOWN, Ohio – Matt Heffinger of Salem thought he’d have to relocate to a major metro region perhaps hundreds of miles away from the Mahoning Valley to put his engineering degree to work.

As it turned out, he didn’t have to look far at all.

Instead Heffinger, a recent graduate of Youngstown State University’s additive manufacturing program, seized an opportunity at Center Street Technologies, home to one of the largest and most sophisticated 3D printers in the world.

“Being able to be involved in something like this is exactly what I was looking for,” he said.

Heffinger was graduated in May 2020 and worked as an intern at Center Street for about a year before he was hired on full-time just after earning his degree. “The first time I walked in here and saw this machine, I thought to myself I have to be a part of this.”

Center Street and the National Center for Defense Manufacturing and Machining, based in Latrobe, Pa., yesterday received $9.4 million in federal funding to support work in additive manufacturing for the U.S. Department of Defense.

“Being able to maintain my roots and stay around here for a career is really rewarding to me,” Heffinger said. Another YSU graduate, Alex Fitzgerald of Warren, was also recently hired at Center Street Technologies.

Attracting and training young people to this form of manufacturing is a core component to what the company and other partners are trying build for the future of the Mahoning Valley, said Center Street President Michael Garvey. “It’s our intention to use the talent here in Youngstown,” he said. “We’re convinced that we can re-skill different people into this technology and create the jobs we’ve all been talking about.”

U.S. Rep. Tim Ryan, D-13, joined Garvey, America Makes Executive Director John Wilczynski and others during a check presentation event Wednesday at Center Street’s plant on Ohio Works Drive.

Garvey said the federal funding would be first used to develop technologies and products for the U.S. Department of Defense. Center Street’s printer is 25 feet deep, eight feet high and 12 feet wide – big enough to park a full-size SUV with plenty of room to spare. The build table is designed to handle 60,000 pounds.

“The equipment and technology makes this one of the most sophisticated hybrid additive manufacturing machines in the world,” Garvey said.

Additive manufacturing is a process that uses digital designs and machinery to print 3D components and finished products made of a variety of materials. In this case, Center Street uses a polymer and carbon mix that is distributed through a large nozzle that navigates the digital pattern on a build table, constructing the product layer by layer from the bottom up.

The project would begin with Department of Defense contracts, such as developing maritime and aerospace products, Garvey said. However in time, the lessons learned from the government work will likely transition to commercial applications in the private sector.

He gestured to a control cabinet that was printed at Center Street that was specifically designed to optimize space in a C-130 transport cargo plane. “We printed that control cabinet in less than a day,” Garvey said. Were a more conventional method of manufacturing used, the project would have taken about six weeks, he said.

“There’s time savings, costs savings and a readiness factor involved here,” he said. “There’s a lot of opportunity here.”

Garvey said projects such as this have been in the works since 2012, when the Obama administration announced the first of its advanced manufacturing hubs, America Makes, in Youngstown.

America Makes is overseen by NCDMM, based in Latrobe, Pa.

“We really look at this from a three-pronged approach: technology, education and ecosystem development,” said America Makes’ Wilczynski. “We’ve been talking about large-scale additive manufacturing for eight years. This is exactly the kind of story we need to tell so investment keeps coming into the technology.”

About four years ago, Garvey met Charles George, the president of Strangpresse, a local company housed in the Youngstown Building Incubator’s Tech Block Building No. 5. Strangpresse has developed advanced extrusion technology that is used at Oak Ridge Laboratories, and the two created Center Street in order to combine capabilities and build the new 3D printer.

Garvey then approached the Cleveland-based Manufacturing Advocacy & Growth Network, or Magnet, for assistance with the design and construction of the printer.

“Mike came to us with this brilliant idea,” said Ethan Karp, CEO of Magnet. “Bringing his partners together with our engineers over the course of a year and a half, we actually built this thing.”

Magnet essentially designed and engineered the project, Karp said, and subcontracted the physical construction of the printer. “It’s just such a triumph for the region.”

Congressman Ryan said his role was to help facilitate funding through the 2020 federal appropriations bill for the project. Ryan is vice chairman of the Defense Subcommittee of the U.S. House Appropriations Committee.

“The Department of Defense can use this technology to make products in hours instead of weeks,” he said. “It reduces the burden on the taxpayer. That’s all being done here.”

Parts for tanks, trucks, and aircraft could all be producing using this type of technology at Center Street, he said. “They can build pretty much anything.”

Ryan observed that this is an industry that will continued to grow and will help redefine the very nature of manufacturing in the Mahoning Valley, positioning it for the future.

He noted projects such as Ultium Cells LLC — General Motors and LG Chem’s $2.3 billion electric battery plant under construction in Lordstown — the production of the all-electric Endurance pickup at Lordstown Motors Corp., and new partnerships between YSU and the University of Texas El Paso in fields such as hypersonics bode well for the economic diversity of the region.

“Additive manufacturing, hypersonics, business software, battery storage, electric vehicles – that’s now a portfolio of economic development that we have going on,” Ryan said. “Success breeds success, talent breeds talent, and investment breeds investment. This is just the beginning.”

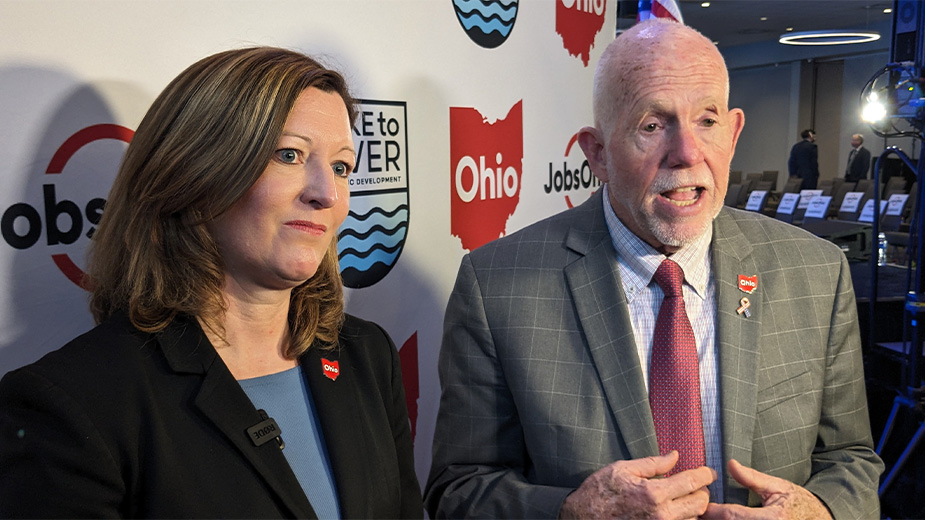

Pictured at top: U.S. Rep. Tim Ryan with Center Street engineers and YSU grads Alex Fitzgerald and Matt Heffinger.

Copyright 2024 The Business Journal, Youngstown, Ohio.