Continuation of America Makes, Defense Partnership Recommended

CANFIELD, Ohio – The Joint Defense Manufacturing Council recommended the strategic partnership between the U.S. Department of Defense and America Makes should continue.

The announcement came Tuesday morning at the America Makes Members Meeting and Exchange, or MMX, at Waypoint 4180. America Makes presented information to representatives from the Joint Defense Manufacturing Council during an April evaluation.

America Makes Executive Director John Wilczynski and Robyn Vialva, government program manager at the U.S. Air Force Research Laboratory, revealed the recommendation during the State of America Makes address, which kicked off the gathering that runs through Wednesday.

Vialva said the JDMC listed several recommendations.

“Moving forward, they recommended a five-year strategy to strengthen U.S. competitiveness in additive manufacturing,” she said.

They want a focus on new challenges to address the industrial base, she said. The council also recommended expanding the satellite centers to increase reach with the regional models that America Makes uses.

“Also the comment was to look for ways to accelerate supplier qualification efforts,” Vialva said. “Also, expand upon international standards involvement” was among the recommendations.

Additionally, the council recommended devising standards for data management and intellectual property, “and that’s something that America Makes has been involved with in an ongoing effort, so they’re only moving and refining the capabilities that they have made available for the membership,” she said.

Regarding education and workforce development, JDMC recommended expanding on industry relevant credentials and scaling high value programs, Vialva said.

“So that overarching question, ‘Is there a continuing need for the institute?’ Yes, there is,” she said. “This is significant because it ensures investment from the DOD moving forward and into the future.”

Wilczynski told the crowd there’s still a tremendous amount of work to do.

“Even though we’ve done a lot and the community has really pulled together and made a tremendous impact, there’s some number X of that that needs to be done moving forward,” he said.

“There’s tremendous needs when we look at materials …,” Wilczynski said.

The recommendations from JDMC parallel what America Makes and the people in the industry believe needs to be done too, he said.

About 360 people attended the event, representing nearly 220 companies and organizations.

Terry Wohlers, head of advisory services and market intelligence at Wohlers Associates, powered by ASTM International, delivered a presentation on The Future of Additive Manufacturing.

“No one really knows, including me, exactly what the future holds and how it will unfold over the foreseeable future,” he said. “But there’s some ways we can pick up tips on where it might go.”

Applications will drive the growth of the industry, Wohlers said.

Qualification of materials is time consuming and expensive.

“But it’s the key to unlocking commercial applications in my view,” Wohler said. “Not for all materials and all applications, but some of the aerospace and medical devices and so forth.”

The government has been supporting some of those programs, including one material that’s being qualified through an America Makes program, he said.

There’s also an increase in additive manufacturing growth in China, Wohlers pointed out. That was illustrated by 42 Chinese companies exhibiting at this year’s Rapid + TCT. That’s North America’s largest additive manufacturing and industrial 3D printing event.

“And some of these products and companies are very serious,” he said. “On par, and in some cases, better than what you’re going to see in the West.”

Wohlers also said industry trends indicate continued growth.

“We think it’s going to approach $100 million in about 10 years from now,” he said.

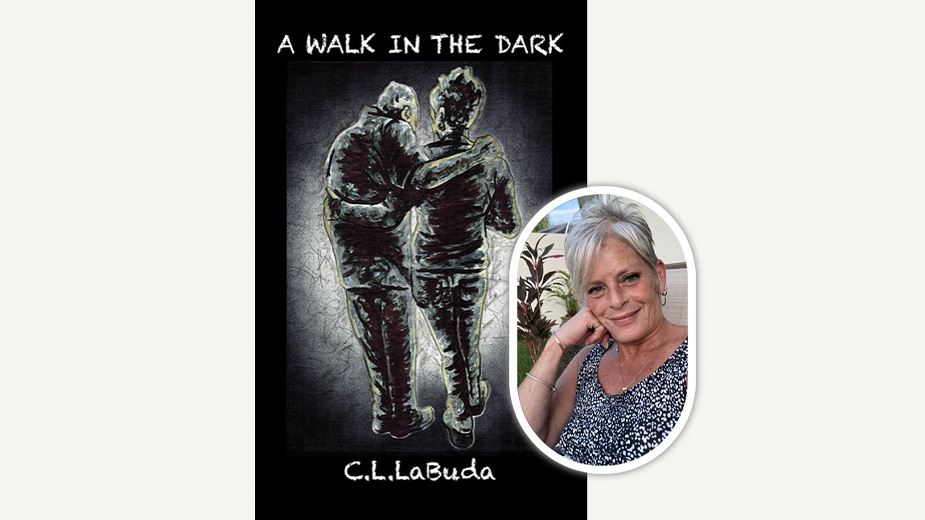

Pictured at top: John Wilczynski, executive director of America Makes, and Robyn Vialva, government program manager at the U.S. Air Force Research Laboratory.

Copyright 2024 The Business Journal, Youngstown, Ohio.