Creating a Foundation for Hybrid 3D Printing | Tricks of the Tradesman

YOUNGSTOWN, Ohio — In fall 2020, JuggerBot 3D submitted a proposal to the U.S. Army to develop new technology, materials and overall technique for additive manufacturing.

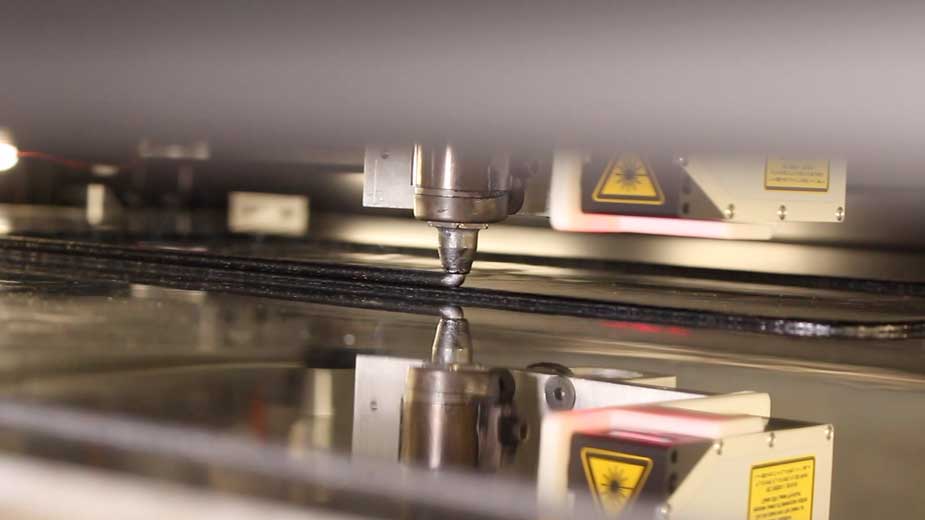

The technology, direct-ink write, allows additive manufacturers to process two-part thermoset materials, says Zac DiVencenzo, president. JuggerBot 3D was awarded phase one, a six-month project that was about $165,000.

“The objective through the United States Army was to develop a new technique that would allow people to process thermally activated materials, which in a sense, is a thermoset material,” DiVencenzo says.

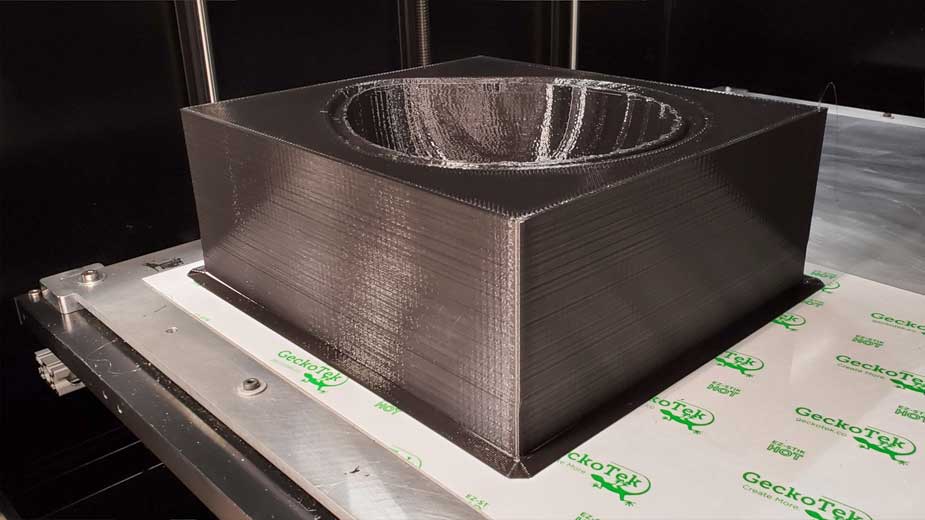

JuggerBot created a baseline for the materials and process, and even developed functionally-grade thermoset parts. The goal was to demonstrate the company’s ability to 3D print those parts in a variety of ways: thermosets with thermoplastics, thermosets with metals or other manufactured components, “and even thermosets on top of thermosets,” he says.

JuggerBot worked closely with Penn State Behrend on developing some of the materials. The campus has years of experience in processing polymeric materials, “plastics in particular,” says Greg Dillon, chair of the college’s Polymer Engineering and Science program.

In 2020, the Polymer Engineering and Science program emerged with an emphasis on materials science of polymer systems.

“So now we have a faculty that goes across all of that spectrum,” Dillon says. “All the way from the fundamentals of polymer science, the chemistry, molecular structure, all the way up to product design and processing and evaluation.”

Hear from DiVencenzo and Dillon about creating a foundation for hybrid 3D printing in the video above.

Ready to get started with 3D printing? Click HERE for the Tricks of the Tradesman!

Copyright 2024 The Business Journal, Youngstown, Ohio.