Executives: Plant to Produce Over 1,000 Monarch Tractors This Year

LORDSTOWN, Ohio – The first five of what is likely more than 1,000 all-electric MK-V Tractors slated for production this year rolled out of Foxconn Ohio’s plant here Tuesday, energizing potential for the sprawling former General Motors factory.

“It’s going good so far,” said Mark Schwager, president and co-founder of Monarch Tractor, the company that has designed a driver optional EV tractor that Foxconn is building for the California-based manufacturer. “These first units are a testament to the speed in which we’ve got this going.”

Schwager said Monarch has made several improvements since the tractor was first displayed at the plant last August. Most importantly, production costs have come down substantially, while engineering changes have enhanced the vehicle’s durability.

“This tractor is now completely certified for the lifetime that we expect,” he said, which could be 20 years. He confirmed that Lordstown would produce at least 1,000 of these tractors this year.

“We’re looking to get into the thousands, so more than 1,000 this year,” he said.

About 100 guests and dignitaries attended a ceremony at the plant Tuesday afternoon to welcome the first MK-Vs made locally.

Before the Lordstown rollout, the tractors were manufactured at Monarch’s plant in Livermore, California, said Carlo Mondavi, Monarch’s co-founder and scion of the Napa Valley winemaking family.

Some 60 MK-Vs were produced in California in partnership with Foxconn, he said. Those are now in the hands of customers and should be working in the field this year.

“The exciting thing about what we’re doing right now is that these tractors are the very first off the line, but we’re about to have scale,” Mondavi said. “Speed and scale is important, and we’re moving as quickly as we can to get tractors out to all of our customers around the world, starting here in America.”

Mondavi emphasized that the MK-V presents opportunities for farmers everywhere to realize long-term profitability, since the vehicle is driver-optional and is powered by batteries that can be swapped out as the other recharges.

“Right now, 45% of farmers are not profitable,” Mondavi said. “By being electric, by being driver-optional, by having the technology that we have, we make farmers greater profits, greater earnings each year.”

Second, the MK-V helps remove the reliance on fossil fuels and move to methods such as renewable farming, Mondavi said. It also helps to reduce or even eliminate the use of chemicals – especially herbicides used to eradicate weeds and high grass.

All of this helps to reduce the world’s carbon footprint, which collectively could help arrest the devastating effects of climate change, Mondavi said. He said in recent years, climate change has brought on extreme weather conditions in California, stoking wildfires and drought that have at times wiped out his family’s entire grape harvest.

“Every tractor that comes off the line at Foxconn is going to allow for us to have a massive impact,” Mondavi said.

Kia Behnia, who owns Kiatra Vineyards in the Napa Valley, purchased two of the five tractors produced at Foxconn.

“Our vision is to create smart vineyards,” he said, noting that he’s used important data-driven technology to manage his operation. Automation is critical to this, and the MK-V is a perfect fit for his vineyard. “We need technologies that are simple to use,” he said. “We’re putting a collection of these technologies into our farm and showcasing that to other farms so that they can get the same benefits and put it to use.”

Behnia said adopting Monarch’s MK-Vs was a “no-brainer,” as the tractor is self-guided and can mow and till more frequently at a lower cost than having a crew perform those tasks manually. With the MK-V, a farmer can essentially “train” the vehicle to operate automatically and follow the precise path an operator would during a workday.

Moreover, the MK-V produces zero emissions and eliminates diesel fumes that could damage crops, he noted.

Behnia displayed a video depicting an earlier version of the MK-V moving along row after row of grape vines at his vineyard during a spraying operation – the first in the Napa Valley to use an automated tractor.

“It’s quite amazing,” he said. “This will be the first year we will be diesel-free in the vineyard.”

Rick Rajaie, vice president of Foxconn’s EV operations in the United States, told reporters after the event that its his company’s intent to maximize the efficiency of the former GM plant, a 6.2 million-square-foot factory that once produced more than 300,000 vehicles per year.

“Rest assured, the Foxconn Ohio team has diligently worked with a number of partners to bring additional products and prosperity to the region,” he said.

As for when any announcement would be forthcoming on a new product and partner at the plant, Rajaie responded “very soon.”

Taiwanese tech giant Foxconn purchased the plant for $230 million in May 2022 from Lordstown Motors Corp., which acquired it from GM after the Detroit automaker shut the plant down in March 2020.

Foxconn currently builds the all-electric Endurance pickup for Lordstown Motors per a contract manufacturing agreement the parties signed as part of the plant acquisition in May.

Monarch and Foxconn also signed a contract manufacturing agreement last August, and production of the MK-V began in California during the fourth quarter of 2022, Rajaie said.

Production of the tractor at Lordstown started approximately two weeks ago, five days ahead of schedule.

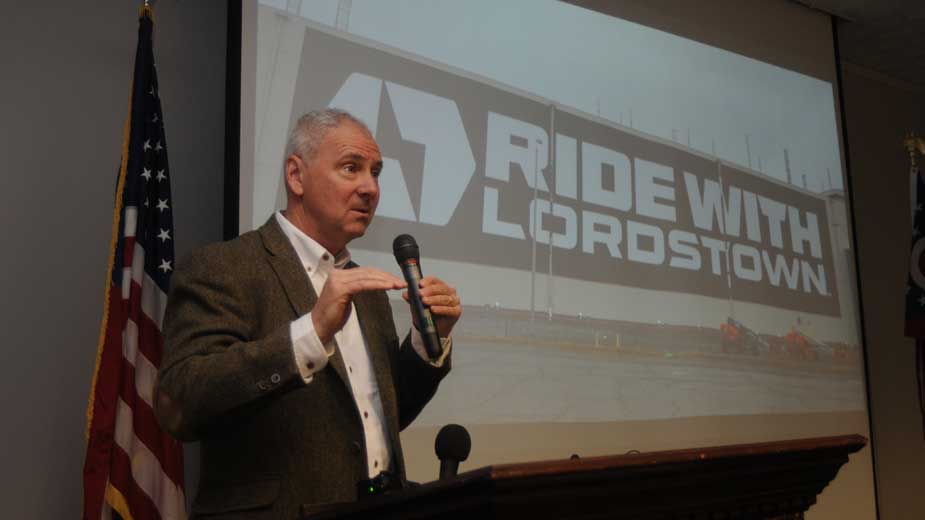

Pictured at top: Carlo Mondavi, co-founder of Monarch Tractor.

Copyright 2024 The Business Journal, Youngstown, Ohio.