Girard Manufacturers Prove Their Resilience

GIRARD, Ohio – The section of Girard that hugs the Mahoning River – once a stretch of bustling industry where thousands were employed – remains the home of a productive manufacturing base that has shrunk but nevertheless remains essential in the city’s economy.

Major manufacturers such as The Youngstown Sheet & Tube Co. and Indalex Aluminum Corp. are long gone, but others have stuck it out through some of the region’s toughest times and have successfully adapted to the demands of the changing industrial marketplace.

Most important, these companies haven’t abandoned Girard.

“It’s my hometown,” says Robert Malito, president of Girard Machine Co. “It’s where my family settled and, all in all, it’s where the major principals of the company still live.”

Malito is the second generation of his family to run Girard Machine, established in 1946 by his father and another partner out of a garage behind their house on Shannon Road.

“They were both welders who worked during the day, and they converted our garage into a small manufacturing weld shop,” Malito recalls. After work, the two manufactured lawn rollers – cylinders with handles consumers used to flatten their yards after they were mowed. “They sold them to Sears,” he says, “and that business grew.”

By the mid 1950s, the business had outgrown the garage on Shannon Road as it started to take on larger metal fabrication projects, Malito says. It was then that Girard Machine Co. moved to 700 Dot St. The business has expanded several times and today encompasses nearly 75,000 square feet of manufacturing space.

During the 1960s, the company struck up a business relationship with an engineering firm that specialized in designing electric arc furnaces and other machinery for the steel industry, and Girard Machine started to fabricate larger components.

“We kept adding on to those bays, and we put in a heavy manufacturing bay up to a 150-ton capacity,” Malito says. He and his two brothers bought the business in 1983, not long after the industrial retrenchment in the Mahoning Valley.

“The steel economy was slow at the time,” Malito recalls. “So, we’ve diversified quite a bit and one of the big areas we got into was the power-generation industry.”

Aside from manufacturing components for that industry, the company today fabricates heavy steel equipment such as electric arc furnaces, charging buckets and presses for the aluminum industry.

He says the company maintains a relatively small workforce, about 50, but notes that it is one of the largest employers in the city. “We’ve kept it small and family-like,” Malito remarks.

While business levels were lower during 2016, the number of inquiries is on the increase and the second half of this year looks promising, Malito says.

Other manufacturers in the city also report an increase in business.

Vallourec Star, one of the region’s largest industrial employers, is experiencing slightly better business levels since energy companies have resumed oil and gas exploration across the country. The company, based in France, manufactures pipe used in oil and gas exploration. Vallourec reduced its workforce beginning 2015 after oil and gas prices collapsed.

Vallourec spokeswoman Jean Gaetano says rig counts across the country have risen, but prices remain challenging. “Rig count is up, although pricing is still lagging,” she says. “We are running multiple shifts and continue to hire for a variety of positions and shifts.”

Girard splits income taxes generated from the $1 billion pipe mill Vallourec opened in 2013 with Youngstown because it was constructed on land that Youngstown annexed from Girard as part of the development agreement.

But employee cutbacks at Vallourec have affected the city’s bottom line.

In 2013, Girard collected more than $1 million in taxes as a result of the Valourec project. About $460,000 of that was income that resulted from construction and payroll taxes from Vallourec. Last year, the city received $159,000 in income taxes from the plant.

Moreover, the city’s mayor laments that Girard has lost other landmark operations such as Syro Steel, which last year shut down part of its production with a loss of 45 jobs. In 2007, aluminum producer Indalex shut its doors, costing more than 300 jobs.

“The industrial sector isn’t holding up all that well right now,” Mayor James Melfi says. “But we’re hanging on,” he says, praising the success of companies such as Girard Machine and Brainard Rivet Co.

“We’re ahead of our goals for this year,” says Paul Kovach, Brainard’s sales manager. Brainard, a subsidiary of Fastener Industries, is an employee-owned company and moved to 222 Harry St. in Girard from Warren in 1951. The company manufactures fasteners used mostly in the automotive industry.

Brainard is constantly searching for new opportunities and customers in what is a very competitive market, Kovach says. Over the past two years, Brainard has invested in refurbishing older machines and new equipment, such as a five-die, five-blow header machine that has helped bring in additional business. “We’ve added some equipment in our tool room,” he says.

Between 70% and 80% of the company’s business is with the automotive industry, Kovach says. Brainard also manufactures fasteners for the railroad, furniture, agriculture, and metalworking markets throughout the world.

Girard is a perfect fit for the company, Kovach says, and its location provides ample opportunity for expansion should the need arise. “We’ve done it on several occasions,” he says. “It’s one of the key benefits of this location.”

Elsewhere along the industrial corridor, manufacturers have found success in other business sectors, such as the hospitality and entertainment industries.

“The market is very good right now,” says Megan Vickers, vice president of Soft Touch Furniture. The company designs and manufactures furniture primarily for the restaurant and hospitality industry, shipping to clients as far away as Saudi Arabia.

“People who are opening new restaurants are looking for something unique,” Vickers says. “They’re not looking for cookie-cutter furniture.”

Kurt Ingalls, Soft Touch’s director of operations, relates that the company has enjoyed an increase in business because it has the ability to quickly adapt to trends and tastes. “The clients we work with are expecting more on the design side,” he says. “We’re unique in what we do.”

Vickers says the company’s South State Street location is ideal because it’s not far from the Interstate 80 interchange, so access is easy. “We have customers from New York and Chicago, so it’s convenient for people to get to us.”

Plus, the location provides ample room for expansion, Vickers says. “We just added a new addition in 2015,” she says. “We’re always looking at expanding and adding more.”

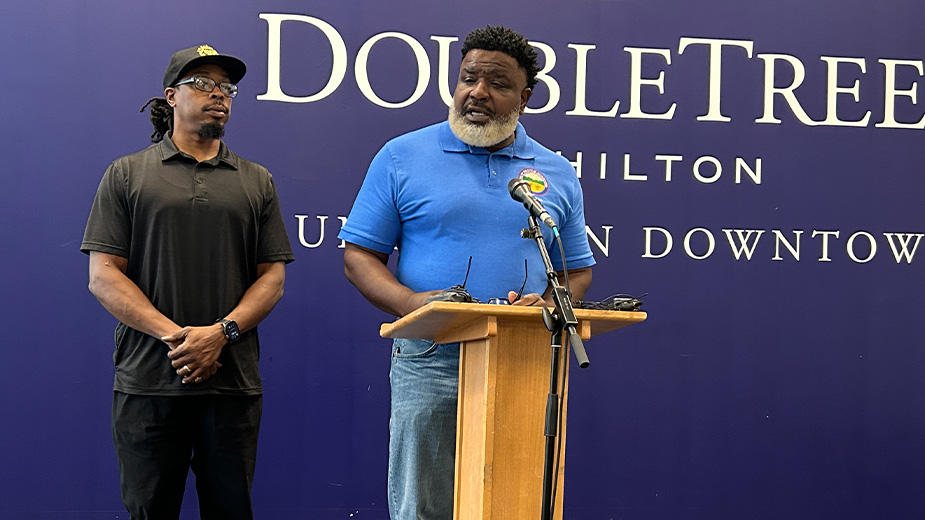

Pictured: Girard Machine Co. President Robert Malito.

Copyright 2024 The Business Journal, Youngstown, Ohio.