Helping Achieve a Perfect Pint of Brew

“The perfect pour should take seven seconds,” says Michael Ervin.

He should know.

Ervin is the founder and owner of Bubble Tech USA, which cleans, repairs and troubleshoots draft beer lines and tap systems.

The Columbiana resident, who calls himself a draft beer technician, put in years learning the business before starting his own company last year.

“I’m not a beer aficionado but I am a perfectionist,” he says. “I want a beer to taste the way it’s supposed to, whether it’s a local beer or one made from a major brewer. The brewer puts a lot of energy and heart and time to get those notes of flavors in their beer and it’s a disservice to ruin it.”

As in brewing, there is a science to maintaining a draft beer system, Ervin says, but it all comes down to temperature and pressure.

Beer that is too cold causes the drinker to feel bloated. If it’s too warm, too much foam comes out. Too much CO2, which propels the beer, affects the flavor.

But when the temperature is just right, the tap lines are clear and the CO2 is set properly, the flavor will be true and the foam – which is waste – will be kept to a minimum.

The goal, Ervin says, is to get the most profit from every keg while keeping the flavor intact.

“We do the little things to help make that perfect pour,” he says.

A native of New Middletown and a Springfield High School graduate, Ervin was most recently the manager of beer and soda systems for Ratermann Manufacturing of California. He spent two or three weeks a month on the road, traveling to trade shows and sales events for the compressed gas company.

Then came the pandemic, and for the first time in years, Ervin found himself at home in Columbiana all the time with his wife and their child. It was then that he started noticing what restaurants and bars were doing wrong.

“We would be out to eat with friends and they’d always want to know about beer, so we’d talk about stuff like how much foam is supposed to be on a pint of beer,” Ervin says. “I would see bartenders tilt the pint glass and dump the foam, and dump the foam, and dump the foam. … The pour could get up to 15, 16 seconds.”

Knowing that they were pouring profits down the drain, he started asking bartenders and managers about their cooler temperature and other things related to the keg system.

He wanted to know about their CO2 levels and what could be disturbing the flow through the lines.

“I’d say, ‘Can I look a your system?’ and I’d start fixing it because it was something to do,” Ervin says.

Before long, he decided to quit his job with Ratermann, stay home with his family and put his expertise to work by starting his own company.

He now has close to 60 accounts, including dozens that he purchased from another local line cleaner who was leaving the business.

Just about every brewpub in the Mahoning Valley uses Ervin’s company, including Noble Creature Cask House in Youngstown, Biker Brewhouse and Paladin Brewing in Austintown, Birdfish Brewing and Sundog Ciderhouse and Winery in Columbiana, Modern Methods in Warren, Numbers Brewery in Lisbon and Lake Milton Brewing.

He has already had to hire one employee, who helps him on service calls.

“The brewers know what they’re doing,” Ervin says. “They hire me because they’re too busy to clean the lines themselves and they also trust me.”

State law requires that tap lines be cleaned every two weeks but Ervin says agents are unable to strictly enforce that rule.

His cleaning ritual involves blowing out the lines with a machine and then running solutions and water through them to remove impurities. The transparent and flexible tap lines are usually dozens of feet long, connecting the kegs in the walk-in cooler to the taps in the barroom.

Ira Gerhart, owner and brewer at Noble Creature Cask House, says Ervin does “a great job.”

As a brewer, his focus is on flavor and he doesn’t want it ruined. He brings in Bubble Tech USA every two weeks to service his draft system.

“A lot of places, even some nicer places, don’t have that cleaning regimen in place,” Gerhart says. “You’re paying a premium for the beer and it could be a poor representation of what the brewer intended. The customer, the bartender and the brewer aren’t happy.”

Sometimes the two week-interval for cleaning isn’t enough.

“If we had a really wild beer on, we’ll clean [the lines] several times,” Gerhart says. “Certain flavors will stick [in the lines], like ginger or coffee. With the time it takes to make an ale, which is two or three weeks, or a lager, which can take about three months, the last thing you want to do is run it through dirty tap lines and ruin the flavor in that last step before the customer gets a beer.”

Gerhart says he has sampled his own beer at other establishments that sell it and could tell that the taste was being altered by dirty lines.

Ervin’s path to starting his own draft beer service went through several states.

After a very short stint at Youngstown State University after high school, he moved to Texas to pursue a career as a firefighter.

The first twist came when he instead took a job with Praxair, the industrial gasses supplier. Ervin’s experience with sales and safety regulations helped him to move up to manager of the Texas plant.

He transitioned into the soda and beer gas systems side of Praxair. One of his biggest projects with the company was designing and installing the beverage systems for AT&T Stadium, home of the Dallas Cowboys.

After several years, Ervin and his wife moved to Columbus to work in Praxair’s office there. Later, he took a job with Ratermann, managing that company’s beverage equipment lines.

While with Ratermann, he was involved with the installation of the Raleigh Beer Garden, a restaurant in that North Carolina city that holds the Guinness world record for most beers on tap, with 397.

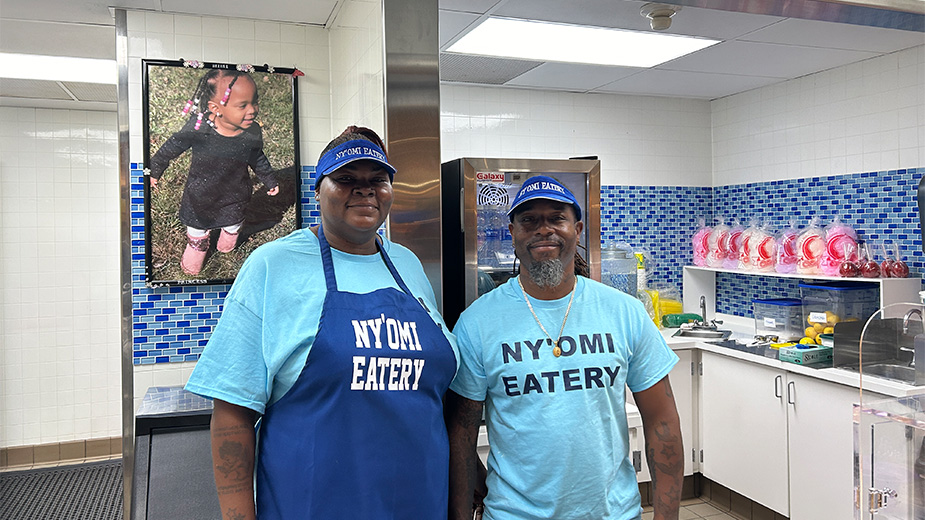

Pictured: Michael Ervin, founder of Bubble Tech USA, stands with a line-cleaning machine behind the bar at Noble Creature Cask House. Ervin visits the Youngstown brewpub every two weeks to clean its system of taps.

Copyright 2024 The Business Journal, Youngstown, Ohio.