Iron City Wood’s New Equipment Automates Pallet Recycling Process

YOUNGSTOWN, Ohio – Iron City Wood Products Inc. has a new addition that will allow the pallet recycling company to sort and cut 20,000 boards per shift, all to specified sizes.

Tina Yanssens, who co-owns the third-generation family business with her husband, DJ, said their new Badger saw, a $600,000 investment, is the first of several in a series that can be put together to help optimize operations and increase efficiency and safety for workers.

The business celebrated the new equipment with a ribbon-cutting ceremony Thursday.

“This is in honor of my dad, Dave Muslovski, and his vision. And I’m proud to carry on his legacy, and I’m glad the third generation is here to keep on working,” Tina Yanssens said.

Her mother, Denise Muslovski, who co-founded the company with her father and serves as the president, was on hand for the launch of the business’s newest initiative toward a more automated future.

Iron City Wood Products moved to its current location, 900 Albert St., about a decade ago, expanding its capabilities of recycling and building pallets, which helps the industry remain waste free.

Although there was not a lot of employee error in the past, D.J. Yanssen said the new machine helps make sure employees waste less wood and all the sizes needed to make custom pallets are created. And while the vast majority of pallets made across the country are one size, he said 75% to 80% of the pallets made at Iron City Wood Products are custom sizes.

When employees manually determine that a wooden pallet can’t be placed into inventory or repaired, it can now be taken apart by the machine and processed.

Using a laser scanner, the machine is capable of determining the size of a board and optimizing how to best cut it into a new size based on the needs of the pallet that builders program in each morning. Several sizes can be requested each day.

Once the boards are cut, the machine then conveys them to where it sorts them into bins by size. Those bins are then moved by a forklift operator and stored until needed to create new pallets.

D.J. Yanssens said stacking and banding the wood allows it to be sold as is to other pallet makers or used by the company when an order calls for it. Iron City Wood also heat treats some of its pallets when necessary, and a lot of the pallets are shipped overseas.

Tina Yanssens said the plant is operating with one shift and employs 50 people. The new equipment, recently purchased from Alliance Automation in Van Wert, Ohio, gives Iron City Wood the capability of processing two and a half times what it used to do with six saws. And it can decrease wood waste by 10%, she said.

Employees will have to do less lifting and fewer repetitive motions, which should lead to better safety.

Whatever is left over also is used, D.J. Yanssens said, by processing it into mulch that can be stained black, brown or red or left natural and sold to local landscapers in bulk. Even the nails found in some boards are collected by a machine during the mulching process and scrapped at a metal recycler nearby.

The company aims for zero waste.

The Yanssens and employees are still learning all the capabilities of the new equipment. Tina Yanssens said they anticipate there will be continuous training for the next couple of months. Two representatives from Alliance Automation were on hand during the ribbon-cutting to help employees learn and fine-tune the machine.

Once it is operating at full capacity, she believes the company will hire more saw operators and pallet builders, allowing them to be more productive.

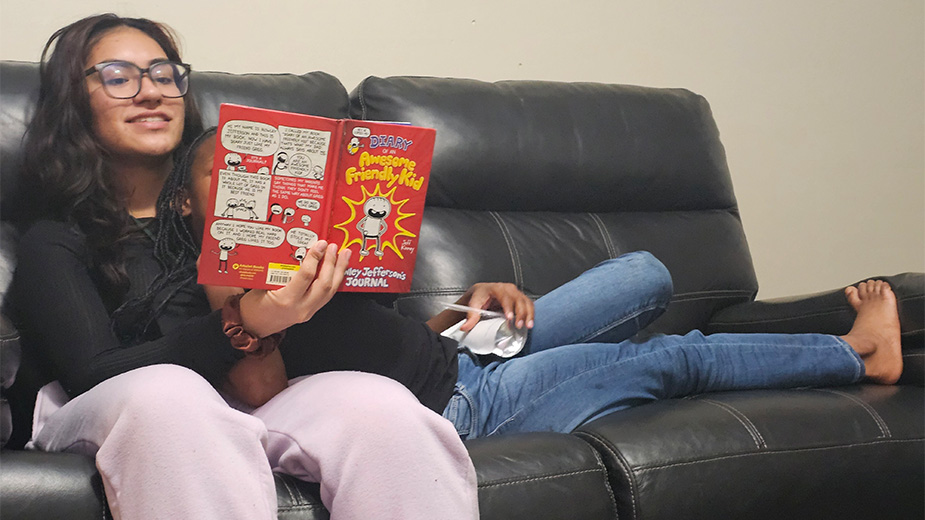

Pictured at top: From left are Brandon Yanssens, the owners’ son and part-time employee; Kayla Muslovski, the owners’ niece; DJ Yanssens, co-owner; Tina Yanssens, co-owner; Denise Muslovski, co-founder and president; Danielle Cope, the owners’ daughter; Tucker Cope III, the owners’ son-in-law and safety and production coordinator; and Andrew Yanssens, the owners’ son and project manager.

Copyright 2024 The Business Journal, Youngstown, Ohio.