Layered Approach to Build 3-D Manufacturing Cluster

YOUNGSTOWN, Ohio – Northeastern Ohio is “ideally suited” to emerge as a national leader in additive manufacturing technology and positioned to develop a long-term business and economic culture around it, says a comprehensive study released this morning.

“We started working on it in December of last year,” says Barb Ewing, chief operating officer at the Youngstown Business Incubator. “It took about six or seven months, but it helps us identify the kind of programs we need from all angles.”

The study – “The Asset Map of Additive Manufacturing Opportunities in Northeast Ohio” — was compiled by four organizations: the incubator, America Makes, Team NEO and Magnet. The analysis presents what development officials say is a “roadmap” on how to develop an additive manufacturing cluster in the region that encompasses manufacturing, supply networks, education and training, research and workforce development.

“When you do cluster work, it’s often theoretical,” Ewing says. “This is not. This is a practical working document. It’s very pragmatic.”

The full 64-page study was made public for the first time today, although a synopsis of the findings was introduced at rol-lout sessions here and in Akron and Cleveland.

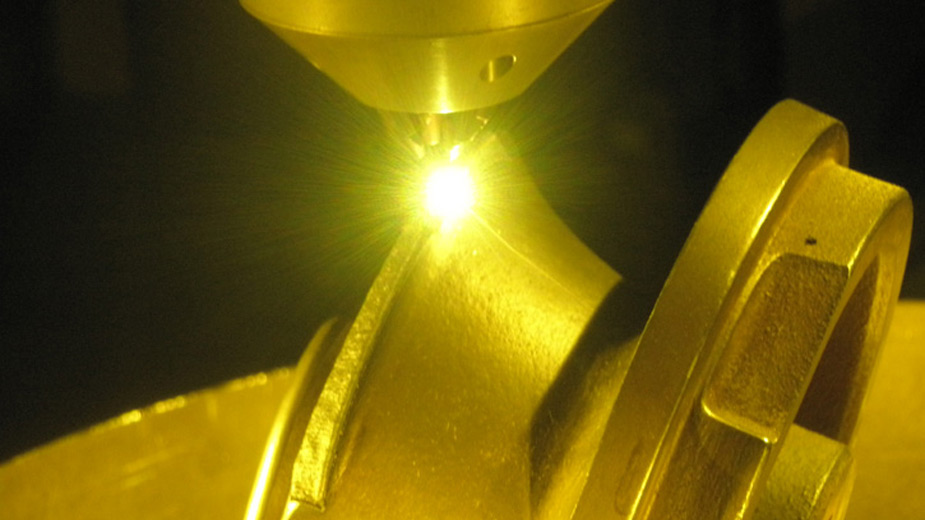

Additive manufacturing, or 3-D printing, is a process that uses a software-driven automated process to dispense materials — liquid metals or polymers, for example – and build a part or component from the bottom up. The process eliminates waste and could save manufacturers money in tooling or through producing parts in lower volumes.

The study presents definitive goals and recommends steps on how to achieve these objectives, Ewing says. The five key goals of the study:

- The formation of a regional national innovation cluster that relies heavily on focused engagement with America Makes and that establishes northeastern Ohio as the center of additive manufacturing in the Midwest.

- Drive expanded applications of additive manufacturing for tooling, fixtures and enhanced manufacturing productivity by investing in technical support, capital equipment, workforce development and industry-based educational programs.

- Use formal education and workforce training initiatives to boost the adoption of additive manufacturing and place a strong emphasis on the development and retention of design engineering talent.

- Build out supply chain strength in key markets such as automotive, aerospace, and biomedical industries.

- Establish a framework that will foster entrepreneurship and commercialization of additive manufacturing supply chain technologies, as well as the northeastern Ohio “maker” community.

Each goal comes with recommended actions that mostly follow a four-year time frame. The study, for example, advocates building technology transfer programs that would extend beyond America Makes’ intellectual property to include other research institutions.

Among the longer-term recommendations – five to seven years hence – is the creation of mechanisms that encourage the sharing of foundational intellectual property that would advance technology without compromising private commercial opportunities. Other actions include engaging with Michigan-based additive manufacturing hubs that have recently attracted some European companies, and identifying additive manufacturing assets in western Pennsylvania that include suppliers, original equipment manufacturers and colleges and universities. Establishing these partnerships could lead to multi-state proposals targeted for federal grant support.

The study recommends, over the next two years, that efforts continue to build off the hybrid manufacturing expertise underway at YBI’s Precision Printed Parts Network to integrate additive manufacturing into traditional production operations, while stepping up informational seminars on the technology.

Future programs would include new academic curricula and efforts to link industries such as aerospace and automotive to additive manufacturing. The automotive industry, for example, could be linked to a core additive manufacturing strategy.

Moreover, northeastern Ohio possesses enough talent and expertise that should be leveraged to accomplish the long-term goal of cluster development here.

The study identifies 165 companies in 18 counties in northeastern Ohio that have some association with or are using additive manufacturing. These companies are materials manufacturers, parts producers, research and development organizations, processors, engineering and design firms and suppliers.

Northeastern Ohio is home to 2,000 companies in the metals manufacturing, plastics and rubber processing sectors, the prime target markets for additive manufacturing technology, the study says.

Last year, revenues from additive manufacturing’s primary global market increased 25.9% to $5.2 billion, the study reports. In North America, revenues could be as much as $1.9 billion.

The total market in the United States for plastics, polymers and metals manufacturing stands at roughly $730 billion, while the available market in northeastern Ohio could be about $17 billion. By 2020, the market potential for tooling alone could be $1 billion in the region, the study finds.

Ewing says the goal of the study is to raise greater awareness of how additive manufacturing can fit into the regional economy and manufacturers in northeastern Ohio with greater opportunities.

“That’s certainly one of our goals,” she said. “The other is to develop a supply chain and build an economy around it – manufacturing, software development, education – you name it.”

Copyright 2024 The Business Journal, Youngstown, Ohio.