Lordstown Is ‘Ground Zero’ for GM’s All-Electric Future

LORDSTOWN, Ohio – A day after General Motors announced its $20 billion commitment to an all-electric vehicle lineup, the company declared Lordstown “ground zero” for its transition.

It’s in the village that the automaker will spent $2.3 billion to build a plant dedicated to manufacturing battery cells for all its brands – Chevrolet, Cadillac, GMC and Buick.

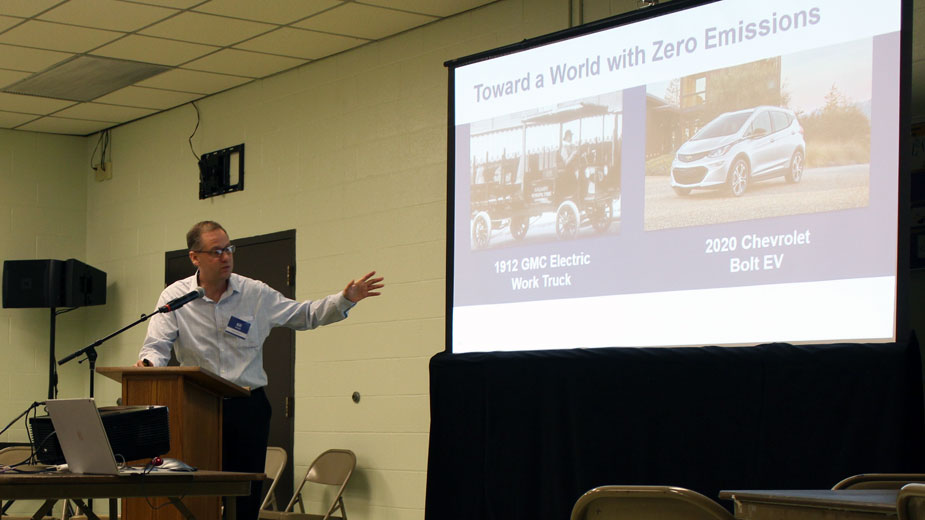

“This is going to be a very aggressive project for us. This will be ground zero for an all-electric future for General Motors,” said John Blanchard, GM’s director of local government affairs, at an information session Thursday.

“This is a fast-tracked project for us, probably the quickest any of us have been involved in. There’s a sense of urgency,” he said.

After announcing a joint venture with LG Chem in December, ground is expected to be broken on the plant later in spring, pending the approval of permits from the Ohio Environmental Protection Agency, U.S. Army Corps of Engineers and other agencies. Construction should be completed by 2022, with production starting a year later. All told, that’s just under three years to get a plant up and running.

By then, General Motors will have 13 electric vehicles on the road powered by the Ultium battery cell, including the reintroduced Hummer line and Cadillac Lyriq. The models were announced Wednesday at an event at GM’s Warren Technical Center, just outside Detroit. To get there, the company will invest $20 billion in electric-powered vehicles by 2025.

“One thing that’s for sure is this proposed facility is very important to GM,” said spokesman Dan Flores at Thursday’s meeting. “If anyone questioned GM’s commitment to an all-electric future, we hope we addressed that. We are absolutely committed and this proposed battery plant here is where it all starts.”

On hand for the Michigan meeting was Lordstown Mayor Arno Hill. After seeing what GM has planned, along with its commitment to sustainable practices – 100% of GM battery cells made since 2013 have been recycled after their useful life has ended and has a company-wide recycled material rate of 80% – he says he’s all in on the battery plant in his village.

“My next vehicle probably won’t be gas. Going up to Detroit and going to Lordstown [Motors on Thursday], this is exciting,” he said. “They made an excellent presentation and we’re going to be a key part of that. I appreciate General Motors still looking our way.”

GM plans to hire around 1,100 workers to staff the plant. During the hiring process, which will include a “handful” this year but will begin in earnest closer to completion, the company is looking for the most qualified workers possible. Former General Motors who took buyouts during cuts at the Lordstown Assembly will be eligible to work there, said manufacturing planning director Bill Stiles. In February, executives from LG Chem said the company would focus on hiring local workers.

“This community has tremendous experience in manufacturing and that’s why we had the confidence the Mahoning Valley could be part of the reinvention of this company,” Flores said.

The manufacturing process for battery cells, Stiles said, is vastly different than car assembly. The process involves mixing raw materials into a “goop” that’s rolled onto copper and aluminum foils before being pressed, baked, cut and folded together before packaging and charging.

“It’s a clean room that’s environmentally controlled and humidity controlled. It’s completely different than the typical manufacturing environment,” he said. “There’s automation that cuts the sheets and then folds it almost like origami. … Things are done to a much higher specification than traditional [car] assembly.”

Among the jobs in the plant will be material movement, process monitoring and technical jobs monitoring equipment, he added.

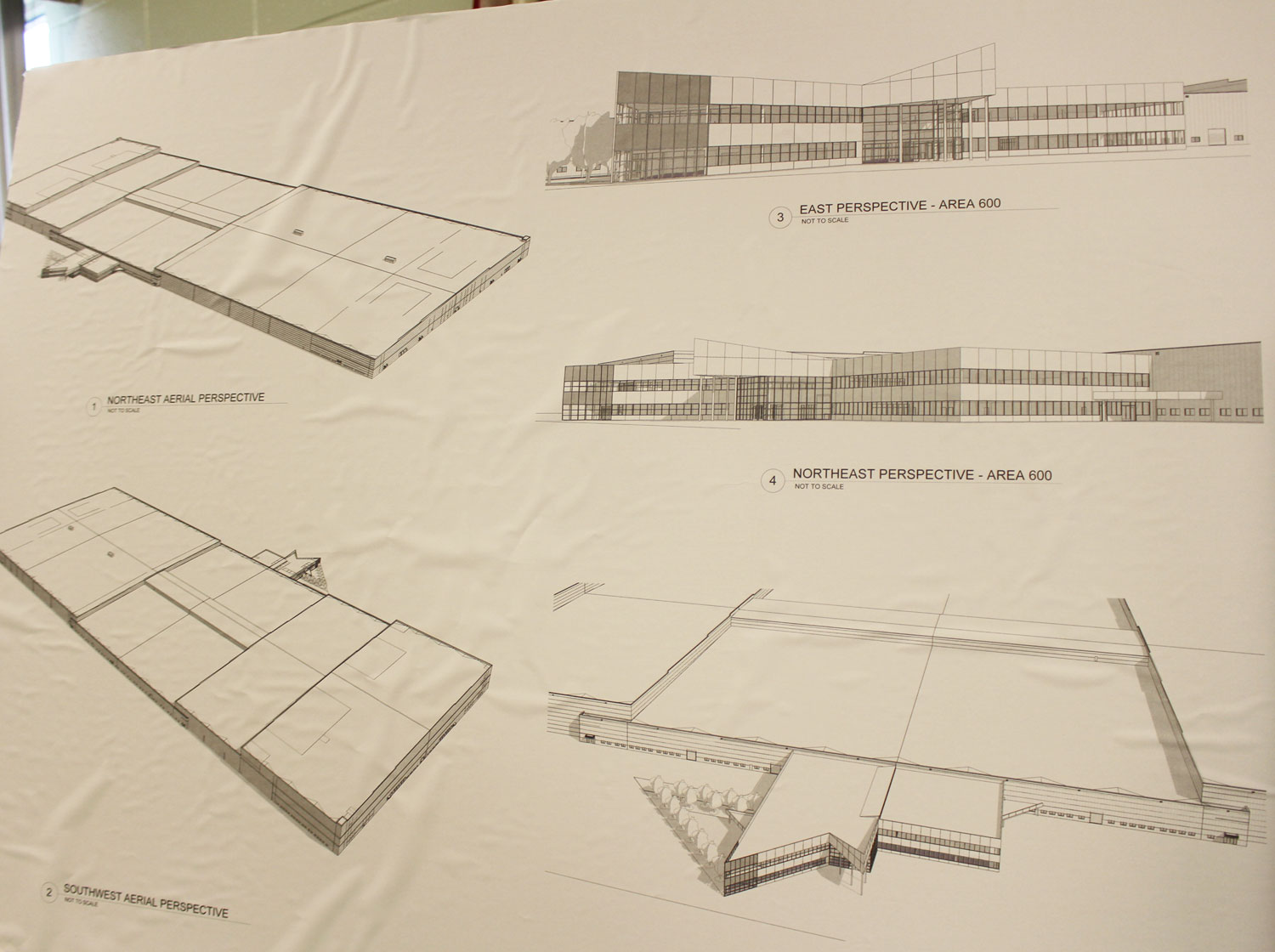

The 1,100 workers will be under one roof, in a 1.7 million-square-foot workspace – equivalent to roughly 31 football fields. Since battery technologies are constantly advancing, the plant is being designed around the equipment that will be used and will be adaptable to innovations that arise as the tech develops, Stiles said.

Branden Brickles, the construction project manager for GM, said he’s working with a 60-man design team. Finalizing labor for the project is still in the distance, but said he’s meeting with local union leaders Friday.

At the information session, the General Motors employees took questions from area residents, with many focusing on environmental concerns and traffic. A traffic study is underway, Brickles said, with the site plans currently calling for one entrance each for employees and truck traffic, the latter of which will move directly onto state Route 46. Those plans may change after the study, he said.

As for the environmental concerns, the company will create more than 170 acres of wetlands near Mosquito Creek Reservoir to offset the 66 acres of wetland at the site the plant will be built. Work there will begin at the same time work begins at the battery cell plant, said environmental manager Jim Hartnett, adding that GM is working with the Stream & Wetlands Foundation to develop the mitigation site, which is currently farmland.

GM will monitor the site for 10 years before returning control to the Ohio Department of Natural Resources, who will then take over maintenance of the site.

“Sites need three critical things: hydrology, soils and plants. The soil that’s there is historically hydric, [meaning] it was there before they started farming but now it’s drained, which means we’ll restore the hydrology,” said Aaron Van Ostren, director of operations for the foundation. “Finally, with those two factors come plants. They’re hydrophytes, they like to have wet feet, and with those first two restored, they’ll be happy and thrive.”

The mitigation site will also feature a wide range of wetland environments, from forest to scrub to meadow, he said.

“It brings a greater diversity of habitats and wildlife than what’s there currently or what was [previously] at the site,” he said.

Pictured at top: General Motors’ manufacturing planning director Bill Stiles was among the company representatives at an information session Thursday.

Copyright 2024 The Business Journal, Youngstown, Ohio.