Lordstown Motors Drives Interest with Plant Tour

LORDSTOWN, Ohio – Lordstown Motors Corp. is about a month away from naming the battery supplier for its Endurance electric pickup truck, CEO Steve Burns said Thursday.

Lordstown Motors, which plans to begin manufacturing the Endurance at the former General Motors Lordstown plant later this year, has been in talks the major battery manufacturers and is about to pick a supplier, which the company will announce in “30 days or so,” Burns said.

The electric vehicle startup opened the plant to more than 80 local officials and representatives of local and national media outlets Thursday morning. The tour provided many of them with their first opportunity to get inside the plant since Lordstown Motors took it over. WATCH VIDEO

The company’s goal is to produce 20,000 electric pickup trucks in 2021 and bring production up to 60,000 units the following year.

Describing Lordstown Motors as “a small company trying to break into the Goliath of the auto world,” Burns said the introduction of the Endurance would be the equivalent to Ford coming out with an F-150 pickup that achieved 75 miles per gallon.

“The Ohio state motto is ‘With God, All Things are Possible.’ We think we’re going to do the impossible,” Burns said. “We think we’re going to not just make a few vehicles here. We’re trying to change the whole region over to electric.

“It’s a tall order. It starts with the first vehicle,” he continued. “We’re hyper-focused on having a great first vehicle.”

Lordstown Motors will use about 30% of the 6.2 million-square-foot complex, the company’s director of general assembly, Dan Tasiemski, said during a brief tour of the plant floor. In addition to building the vehicle itself, workers will assemble the battery packs and hub motors on site, both of which will require clean room environments.

Burns emphasized that, unlike the situation when the complex was operated by GM, decisions about the plant would be made at the plant.

Cost savings from operating the Endurance are such that if a fleet keeps an Endurance for eight years, it would be the equivalent of buying a Ford F-150 for $14,000, Burns said. Because it doesn’t have a V8 engine up front, the vehicle has a great crush zone and its low center of gravity minimizes turnovers. “The only thing it can’t do is drive to California,” he remarked.

The market Lordstown Motors is targeting – work pickup trucks for fleets – isn’t being targeted by other EV manufacturers, he said. “You rarely get a clean lane in automotive,” Burns said.

The plant has about 50 workers on staff, primarily in engineering, and will add 400 workers by the end of the year for production of the Endurance, but employment will be north of that figure since Lordstown Motors is going to build the battery packs and hub motors on site, Burns reported.

He emphasized an initial preference for hiring as many of the former GM Lordstown workers who are still in the area.

“The people that know this factory the best — from how to turn it on — are folks that have been her before,” Burns said. About half of the plant’s executive team, including the human resource director, came from the plant.

Hiring of hourly workers probably will begin in July, said Rich Schmidt, chief production officer. “It’s a very intensive hiring plan,” he remarked.

Company officials had its first meeting recently with representatives of the United Auto Workers, which Burns described as “a great first meeting.” He expressed his openness to union representation at the plant.

“If workers decide to unionize, that’s fine with us,” he said. Although issues such as health care are “difficult,” he said wages would be “competitive with what anyone is making in an auto plant in the United States.”

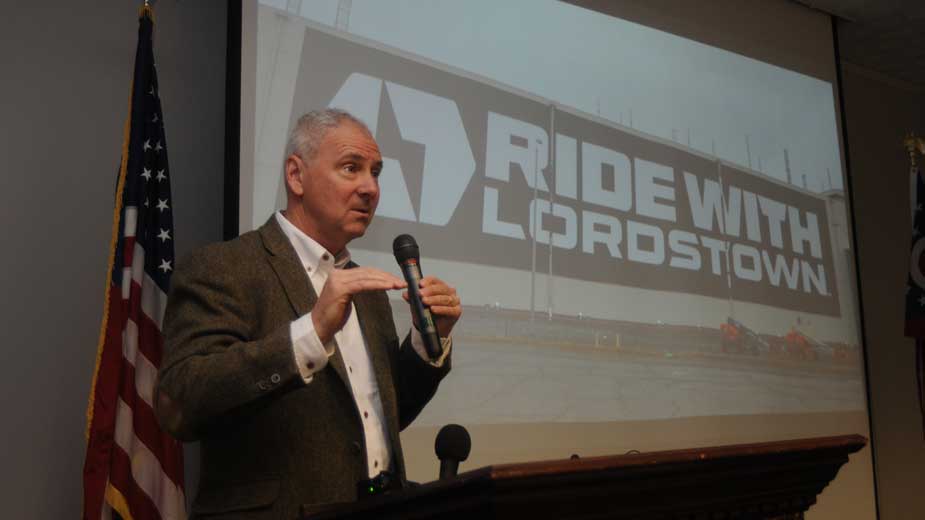

In addition to the “Ride with Lordstown” video that was released last month, company officials showed a second video – which attendees were not permitted to record – of a test drive by Burns of a vehicle with a “donor body” on an Endurance chassis. The vehicle was shown on a test track, , a muddy dirt road and going up a 15% grade.

The charger for the vehicle will be compatible with other EV brands except for Tesla, “which insisted on having its own,” Burns said.

Burns would not elaborate on the status of Lordstown Motors’ capital raise, only stating that the company was “right on target” for its goal, which he previously said is in excess of $300 million.

The company is looking at applying for financing from the U.S. Department of Energy’s Advanced Technology Vehicles Manufacturing Loan Program. “We believe we’re a good candidate for it but we’re not betting on it,” he said.

The company is seeking not just financing but “strategic partners,” and he said Lordstown Motors has attracted significant interest.

Burns said as volume increases at the plant, its suppliers would want to be close. “We can’t make that happen. We just think natural physics will cause that,” he said.

To that end, Lordstown Motors is working with suppliers to potentially have them locate in the plant’s remaining available space. Having suppliers in house “makes sense” to help manage utility and other building costs, Schmidt said.

One potential supplier that won’t be working with Lordstown Motors is the joint GM-LG Chem plant that will be built adjacent to the LMC plant. The batteries that will be made at that plant won’t be compatible with the Endurance, Burns said.

Retooling should begin by the end of March or in early April, plant officials said.

The process of getting the plant up and running for producing its new vehicle was helped tremendously by the care GM took in shutting it down, Lordstown Motors officials emphasized.

“GM did a really great job of shutting down the factory,” Tasiemski said.

“It’s almost like they went off on holiday and didn’t return,” added Ronald Trautzsch, director of stamping and body assembly.

Deeper in the plant, during a tour for media outlets that followed the main presentation and question-and-answer session, a robot that used to engrave vehicle identification numbers on Chevrolet Cruze models was being put through its paces. Lordstown Motors will need about 550 functioning robots to start up, and 200 of the thousands of robots left by GM have been assessed since testing began a couple weeks ago, Trautzsch said.

Each robot is activated and put through 1,000 cycles, he said. Very few have been faulty. A crane company recently certified the overhead cranes in the plant.

“This facility was made for one thing,” Burns remarked. “To have it do anything else would be criminal. We are racing to reconfigure this plant”

Local officials attending the event are enthusiastic about the plant’s prospects.

“It’s great for the Valley,” remarked Marty Loney, business agent for Plumbers & Pipefitters Local 396. “We want to get into the plant and start retooling ad rebuilding. That’s the focus for us.”

“It’s amazing to have a direct competitor for one of the best-selling trucks, the F-150, located here in Ohio and Lordstown,” Youngstown First Ward Councilman Julius Oliver said.

Oliver revealed that a $10 billion Israeli venture capital fund led by a Youngstown native expressed interest in Lordstown Motors when the councilman mentioned the startup to him.

“He is interested in not only investing in the next best thing but finding the next best thing,” Oliver said.

The Endurance will be priced at $52,000 before federal and state tax credits.

State Sens. Sean O’Brien, D-32 Bazetta, and Michael Rulli, R-33 Salem, have introduced a bill to provide tax credits for the purchase of electric vehicles and charging stations. The bill will have its third hearing in April and the Ohio Senate president is “running it up the flagpole” with his caucus, O’Brien said. He is confident the legislation, which has strong committee support, would be passed by summer break.

“It is actually on a fast track,” he said.

Companion legislation in the Ohio House of Representatives is being introduced by state Reps. Mike O’Brien, D-64 Warren, and Gil Blair, D-63 Weathersfield. The legislation is being drafted and will be introduced in a couple of weeks, O’Brien said.

Pictured at top: Local officials, business leaders and the press were taken on the tour.

Copyright 2024 The Business Journal, Youngstown, Ohio.