Lordstown Motors Endurance Experienced Defects Month Before Recall

LORDSTOWN, Ohio – Electric-vehicle manufacturer Lordstown Motors Corp. first received notice of defects in its new all-electric Endurance pickup more than a month before it initiated a voluntary recall on the product, documents show.

According to a safety recall report filed with the National Highway Traffic Safety Administration, the company received a notice Jan. 20 that a vehicle owned and operated by Lordstown EV Corp., commonly known as Lordstown Motors, had experienced a loss of propulsion. Over the next several days, other Lordstown-owned pickups reported the same problem, documents say.

“Subsequent similar events were reported on other Lordstown controlled vehicles in the following days, and all after a major snow event in Detroit,” the report states.

On Feb. 1, the company said it received a report that a customer-owned Endurance in the Detroit area had also experienced a loss of propulsion. Moreover, the vehicle shifted itself out of the drive position while at a stop.

Further analysis by Lordstown Motors last month determined that a component manufactured by a supplier in China is to blame, according to the filing.

Lordstown Motors informed the NHTSA on Feb. 21 that it would conduct a voluntary recall of 19 vehicles, documents say. The company filed paperwork with NHSTA on Feb. 22 and announced publicly the following day that it had temporarily halted production of the Endurance and initiated the recall.

No injuries were reported as a result of the defects.

According to documents, the company had already halted production of the Endurance at Foxconn’s plant in Lordstown before the incidents. “Plant production was already on hold when these events occurred, and production remains on hold,” the report states.

The NHTSA report includes details that were not initially shared with the public or investors Feb. 23. While Lordstown Motors divulged the propulsion issue, it did not disclose that the Endurance, once stopped, could shift from drive to neutral and then fail to restart.

“Once the vehicle is stopped, it may automatically shift into neutral,” the NHTSA report said. “Once the vehicle is shut off, it cannot be restarted.”

Each of these conditions, the report says, “could result in an increased risk of a crash.”

Lordstown Motors said Feb. 23 that the company would address the recall and production halt in more detail March 6 during a conference call related to its fourth quarter and year-end financial results.

A spokeswoman from Lordstown Motors referred a request for comment to members of the management team. As of the close of business Thursday, no one had responded.

Between Jan. 24 and “early February,” Lordstown Motors conducted a parts analysis, the report says. On Feb. 23, the day Lordstown Motors announced the production halt and recall, the company said it was working with its suppliers on the root cause analysis and possible solutions.

The analysis determined that a cable assembly located between the inverter and motor could lose “high-voltage isolation,” causing an “unexpected reduction of power and eventual loss of propulsion,” according to the NHTSA documents.

Lordstown Motors identified four busbars – these are metal bars, usually made of copper or aluminum, that are used to carry electrical currents – that serve each of the Endurance’s hub motors. Unlike a single motor used in traditional EVs, the Endurance uses four motors at each wheel hub to propel the vehicle.

Amphenol PCD Shenzhen Co., located in the Liao Kent Industrial Zone in China, manufactured the components, according to the report.

Documents filed with the NHTSA say the supplier has developed a new version of the component that will increase the high-voltage isolation barrier.

“Lordstown will replace the BA-level busbars with new BB-level busbars in all vehicles at no cost to the owners,” the report said. Only new BB-level busbars would be used in future production of the Endurance and all BA-level components are to be marked and destroyed, the report said.

All recalled Endurance EV pickups would be refitted with the new component, as well as those now in the plant, the report said.

“The team is diligently working with suppliers on the root cause analysis of each issue and potential solutions, which in some cases may include part design modifications, retrofits, and software updates,” Lordstown Motors stated in a news release Feb. 23.

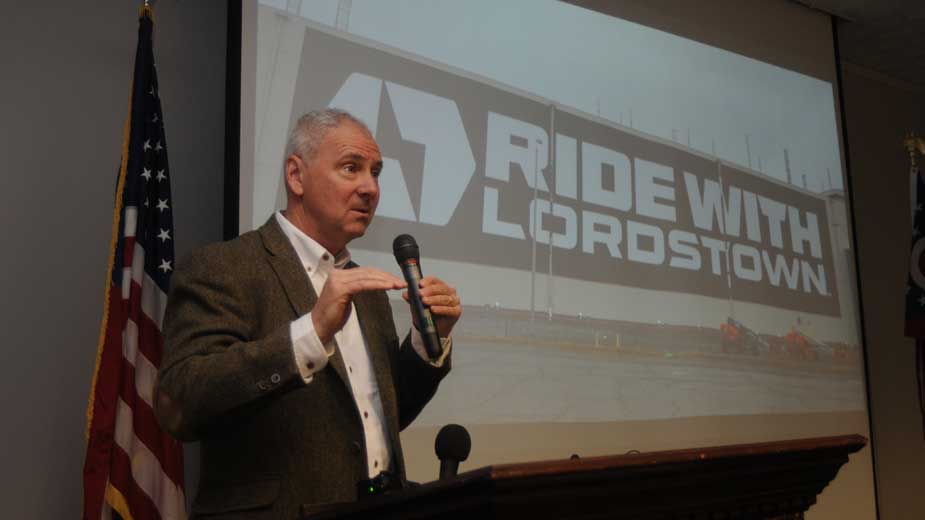

Lordstown Motors President and CEO Edward Hightower said Feb.23 that the company would not resume production or shipments until the issues are resolved.

“While our experienced team has made significant progress in addressing the underlying component and vehicle sub-system issues affecting the Endurance build schedule, we remain committed to doing the right thing by our customers and to resolve potential issues before resuming production and customer shipments,” Hightower said in a statement.

According to the NHTSA report, the company must submit a plan outlining how it will reimburse any owner or purchaser who incurred costs to remedy the defect.

A letter dated March 1 from NHTSA’s recall management division to David Baker, Lordstown director, certification and homologation, states that the company must submit eight consecutive quarterly status reports. The first of these reports is due on or before 30 days after the close of the calendar quarter, the letter said.

Lordstown Motors did not include a timeline in the NHTSA report as to when the issues would be fixed and production would resume.

Foxconn manufactures the Endurance per a contract manufacturing-agreement the companies signed in May. A separate deal that month led to Foxconn’s $230 million purchase of Lordstown Motors’ plant, a 6.2 million square-foot factory once owned and operated by General Motors.

Lordstown Motors began “limited production” of the Endurance in late September and started commercial deliveries in November.

Shares of Lordstown Motors closed 7% higher on Thursday to $1.06 per share.

Copyright 2024 The Business Journal, Youngstown, Ohio.