Lordstown Motors Expects ‘Slow Rate’ of Production in First Quarter

LORDSTOWN, Ohio – Electric-vehicle manufacturer Lordstown Motors Corp. will display its inaugural vehicle at one of the country’s premier tech events today.

The EV startup expects a “slow rate of production” for its all-electric Endurance pickup through the first quarter of 2023, the company said Wednesday in a federal filing.

The company began commercial production of the Endurance in the third quarter of 2022. During the fourth quarter, Lordstown Motors achieved full homologation and received certification from both the EPA and California Air Resources Board, or CARB, to begin customer sales.

Lordstown Motors said earlier that production volume would ramp slowly and accelerate as it resolves supply chain constraints. Through Jan. 3, the company has produced 31 vehicles for sale, of which six have been delivered to customers.

Of the remaining units, the company intends to use approximately 15 for sales, demo drives, marketing and service training purposes prior to sale, Lordstown Motors said. The balance will be sold following completion of updates, final inspection and establishment of service arrangements to meet customer specifications.

“The company expects a slow rate of production through the first quarter of 2023, with supply chain constraints, particularly with respect to the availability of hub motor components, continuing as the primary factor governing volume and timing,” Lordstown Motors said in a statement filed with regulators.

The company plans to display the Endurance pickup at the CES show in Las Vegas this morning, one of the country’s most-watched consumer technology expos.

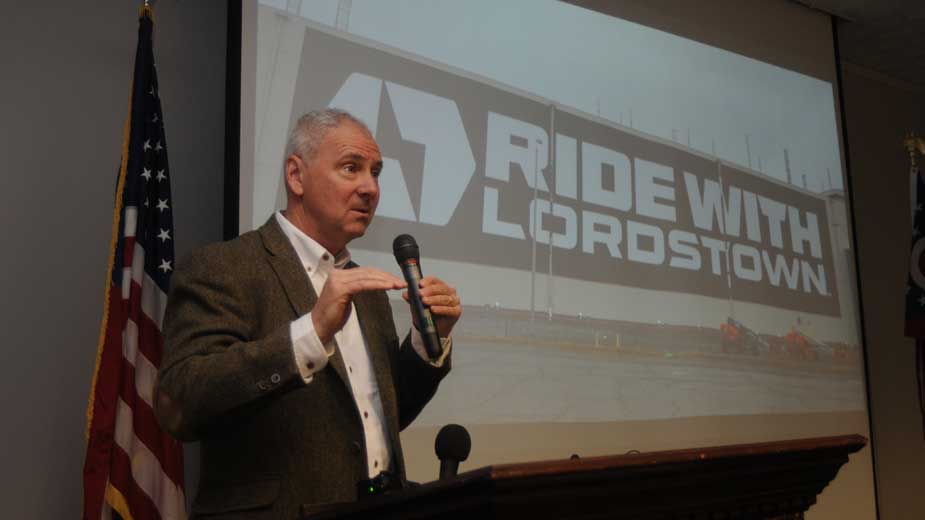

Lordstown Motors President and CEO Edward Hightower will be on hand to participate in the Mobility in Harmony, or MIH, Consortium press conference.

In May, Lordstown Motors sealed a deal with Foxconn that allowed the Taiwanese tech company to purchase the company’s plant for $230 million and serve as a contract manufacturer for the Endurance.

Foxconn has pledged an equity investment of $170 million toward the development of new vehicles with Lordstown Motors. These vehicles will be developed on Foxconn’s MIH platform.

“The sale of the manufacturing plant located in Lordstown, Ohio, to Foxconn was much more than a transfer of ownership,” Hightower said in prepared remarks. “It laid the groundwork for the two companies to collaborate on product development.”

Hightower said the fastest means of achieving innovation is through open collaboration, which is the basis for the MIH Consortium.

The consortium consists of more than 2,400 companies that seek to collaborate to expedite product development cycles and design and optimize the supply chain. The program also encourages sharing components and systems to reduce costs.

“Purchasing the Ohio plant and becoming an employer of highly skilled automotive professionals enables Foxconn to rapidly scale its component and supply chain capabilities,” Hightower said. “It also offers a fast path to production for new or nontraditional OEMs.”

At its peak, when General Motors owned the factor, the Ohio plant produced more than 300,000 internal combustion vehicles per year, Hightower noted. GM sold the plant to Lordstown Motors in 2019 after the Detroit automaker ceased production of the Chevrolet Cruze.

“This capacity is expected to be used to build EVs from multiple OEMs,” he said. “Foxconn can scale the plant for EVs quickly. A core advantage of accelerated innovation is the ability for more OEMs to realize the benefits of scale.”

The Endurance is a finalist for the 2023 North American Truck of the Year.

Copyright 2024 The Business Journal, Youngstown, Ohio.