Lordstown Motors Opens Doors to Demonstrate Viability

LORDSTOWN, Ohio – Rajeev Lamba stands in a bright, clean, but nearly empty 800,000-square-foot section of Lordstown Motor Corp.’s manufacturing plant.

But in a matter of two months, Lamba says the first production lines for the company’s electric-motor system will be installed and making components for the Endurance, Lordstown Motors’ new all-electric pickup.

“Our plan is that by August, we’ll be starting up this line, which will be ready for production,” the director of hub motors told reporters Monday.

It’s a tight time frame, since the startup electric-vehicle manufacturer is sticking with its deadline to start production of the Endurance by late September. That leaves just about a month to perform testing and validation on the equipment in the plant before production of the Endurance begins.

“One month is sufficient,” he said, since most of the critical testing has already been done offsite. The equipment, Lamba said, is in transit from Malaysia.

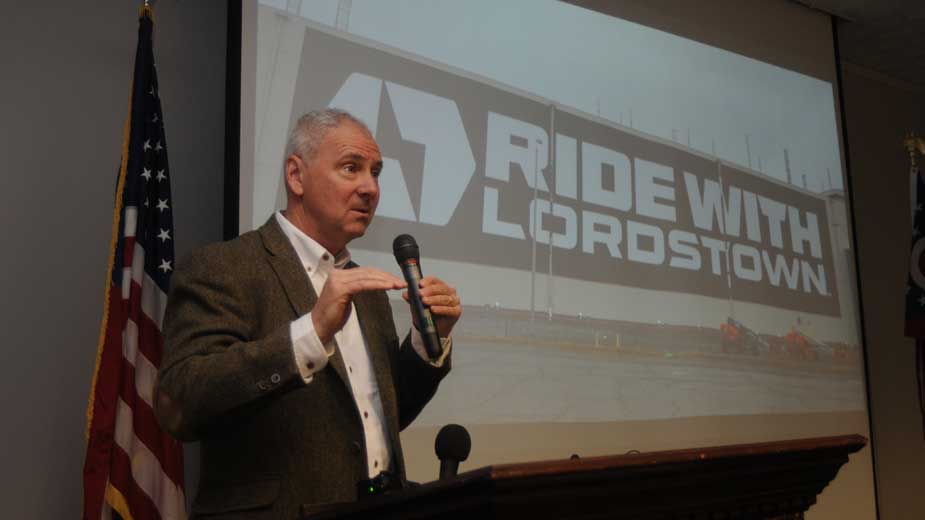

On Monday, the EV startup launched “Lordstown Motors Week” an effort to provide analysts, potential customers, investors and media with an up-close look into Lordstown Motors’ plant, the former General Motors factory that once built the Chevrolet Cruze. The afternoon media session consisted of a plant tour along with test drives of beta versions of the Endurance.

Click HERE for video of an Endurance test drive and the production line.

The event was held amid an abrupt shakeup of the company’s executive team and sagging investor confidence. On June 13, founder and CEO Steve Burns resigned, as did Chief Financial Officer Julio Rodriguez.

A week earlier, Lordstown Motors said in a regulatory filing that it might not have enough cash to remain in business through 2022.

Still, Angela Strand, Lordstown Motors’ new executive chairwoman, told a roomful of local, regional and national reporters that the company’s leadership team is committed to bring the world’s first electric, full-size commercial pickup to market.

“We are seeking additional funding to scale up our capacity and further automation of our manufacturing processes in order to complete our ramp up,” Strand said. “We are evaluating multiple potential sources of funding in addition to evaluating strategic partners,” she said.

Strand said the objective of Monday’s event was to demonstrate that progress is underway at Lordstown Motors.

Gallery images includes the Endurance production line inside the Lordstown Motors Corp. plant, as well as exterior and interior shots of the Endurance.

Shares of Lordstown Motors, which trades under the ticker symbol RIDE, dropped 5.4% on Monday to $10.07. The share price is down more than 50% so far this year.

Reporters on the tour boarded golf carts and were taken to several production departments inside the massive six-million-square-foot plant. These included visits to stamping operations, body shop, paint shop, hub motors assembly, general assembly, and battery manufacturing departments.

Once the tour was finished, reporters were offered test rides on beta models of the Endurance and a military-style Baha car that is used on mostly rugged terrain.

The company did not provide access to top executives for interviews. An internal report released by the company June 14 found that executives had made inaccurate public statements suggesting the company had solid preorders for the Endurance when it did not.

Then a day later, Lordstown Motors President Rich Schmidt told reporters during a panel discussion that indeed there were enough “binding” order to manufacture 15,000 vehicles by May of 2022.

The company walked back Schmidt’s statements two days later, emphasizing it did not have any binding orders for the vehicle.

Strand said the reason for “Lordstown Motors Week” is to give stakeholders insight to the company’s manufacturing process and use of technology.

A critical part of the Endurance is its hub-motor technology. Instead of a single combustion engine under the hood of the truck, the Endurance is propelled by a single electric motor in each wheel. The company said this architecture and design reduces the cost of maintenance and the cost of production.

About half of the 800,000 square-foot propulsion section of the plant would be used for hub motor assembly, Lordstown Motors’ Lamba said.

Once in full production, it would be the largest hub-motor plant in the world, the company said.

“The hub motor will be made here and then shipped to general assembly,” said Darren Post, chief engineer and vice president of engineering.

Meanwhile, employees are busy assembling battery packs for the beta versions of the Endurance in a section of the plant that resembles more of a clean room than a factory. A total of 6,048 battery cells make up a single battery pack for the Endurance.

Among the more highly automated parts of the plant is the body and framing shop, said body shop director George Syrianoudis. Robotic welders left to the company from GM have been retooled to accommodate the Endurance.

“We are using approximately 300- to 350 robots for this Endurance build, but we have 900 robots in this body shop,” Syrianoudis said.

Syrianoudis is among several Lordstown Motors employees who also worked at the Lordstown plant under GM.

John Wood, director of general assembly, said he worked at GM’s Lordstown operation for 12 years, noting his final assignment was to help close it down when the automaker announced it would cease production of the Cruze.

GM sold the plant to Lordstown Motors in 2019 for $20 million. To help with the purchase, GM loaned Lordstown Motors $50 million and kicked in another $25 million in cash when Lordstown Motors went public. GM’s contributions were converted into an equity stake in Lordstown Motors.

Company officials have said one of the greatest advantages the company has is acquiring an already tooled and working plant from GM.

“I’m ecstatic to be part of the team that’s going to reopen it,” Wood said.

Pictured at top: A partially assembled Endurance all-electric pickup truck inside the Lordstown Motors Corp. plant.

Copyright 2024 The Business Journal, Youngstown, Ohio.