Manufacturing Shines Bright in Howland’s Golden Triangle

HOWLAND TOWNSHIP, Ohio Dale H. Gebhardt has worked in the sector of the Golden Triangle within Howland Township more than 40 years.

Over that time, he’s witnessed the rise and fall of mighty companies that once dominated the northwestern corner of the township.

The sector is so named because part of this industrial area is bordered by roadways and railroads that, when you look at a map, form a triangular pattern. The Golden Triangle is a lucrative tax base for Trumbull County and a large employer base as well.

Gebhardt, like others who have stuck it out here, calls himself a survivor. In the wake of the retrenchment of heavy industry in the 1980s, many of the large corporations in the region retreated, never to return. Van Huffel Tube Corp., Alcoa, Brinnell are a few of the names Gebhardt rattles off.

“There’s certainly not as many working out here than there were,” says Gebhardt, now president of Flex-Strut Inc. on Commonwealth Avenue. “It’s changed, but a few of us have survived.”

Delphi Corp. still has an operation nearby – although it’s nothing like the 14,000-strong workforce that the massive complex employed during the early 1980s.

Other companies such as Ajax Tocco Magnethermic, Liberty Steel, Clark Dietrich Building Systems, Trumbull Industries, Wheatland Tube, and Schaefer Equipment Corp. are among the larger manufacturers in the Golden Triangle.

In all, some 30 companies of varying sizes are in the triangle, reports Howland Township Trustee James LaPolla. “The four largest employers pay $150,000 annually in property taxes,” he says.

Plus, the area is home to more than 3,000 jobs that range from managerial positions to hourly wage earners. “Our goal is to secure the jobs we have and to keep existing businesses happy so they can expand,” he says.

Most of the triangle lies within Howland, but parts spill into the city of Warren, LaPolla says.

Many of the buildings in the township that housed some of the old companies were repurposed to fit other industrial operations. Or, these now-defunct companies served as launching pads for offspring businesses that today keep the triangle humming with activity.

Flex-Strut, for example, traces its roots to Van Huffel Tube, formed in 1924 along Dietz Road. Today, the Van Huffel building is used by Trumbull Industries.

Forty years ago, Gebhardt secured a job at Van Huffel’s Power Strut division after returning to the Mahoning Valley from the U.S. Coast Guard, and some of the customers Flex-Strut serves today were once Van Huffel customers. “It’s kind of a situation of maintaining the customers we’ve had a relationship with for 40 years, going clear back to the Power Strut days,” he says.

A Chicago firm purchased Van Huffel in 1985 after the local operations shut down. Gebhardt had the opportunity to relocate there, but decided to venture out on his own – first as a Midwest arm of a California company and then, in 1994, as a partner in Flex-Strut.

“I wanted the kids to grow up and graduate from Howland,” Gebhardt says. “I think we’re in a good location.”

The company manufactures roll form-steel products used by different industries, Gebhardt says. “It’s mostly continuous slot-metal framing that’s used in electrical and mechanical applications.” Other uses are manufacturing and assembling steel laboratory furniture for the pharmaceuticals industry, supplying original equipment manufacturers, manufacturing components for the elevator industry, and serving the solar energy and conveyor industries.

“We have about five major segments that our product line falls into,” he reports. “Hopefully, we find one area or another where we stay busy and continue to grow. We’ve been fortunate enough, since we’ve been pretty steady.”

Flex-Strut has expanded four times in Howland, Gebhardt says.

The last expansion, in 2009, was its largest – a 35,000-square-foot addition that included a new pre-punch roll form line designed to handle larger volumes of product. “We also added a drive-thru doors and steel storage. We didn’t have that before,” he says.

Flex-Strut employs 75, Gebhardt says, and operates four punch lines inside its 102,000-square-foot plant.

Critical to the success of manufacturers in the Golden Triangle is a plan to improve the infrastructure of the area, notes the township’s LaPolla.

Taken literally, the Golden Triangle refers to the section of the township bordered by North River Road to the north and Larchmont Avenue to the west. The Youngstown Belt Railroad slashes diagonally just southeast of where these two roads intersect, creating a “triangle” that holds some of the most productive industrial businesses in Trumbull County.

“When these older companies were built, much of the products were shipped on rail,” LaPolla says. As such, the road infrastructure isn’t adequate for heavy truck traffic, he explains.

The township has prepared a multi-phase plan to reconstruct and resurface roadways, rail crossings, waterlines and storm sewers in the triangle, LaPolla says. “There’s available land there, but new businesses can’t move in without infrastructure,” he says. The township has secured an $80,000 grant to begin the preliminary work.

The triangle has brownfield sites available for development and opportunities for new business, says Sarah Lown, economic development manager at the Western Reserve Port Authority. Two parcels in particular – the former Trumbull Bronze site on the southern tip of the triangle and vacant land across the street from Liberty Steel on North River Road – are strong candidates for redevelopment.

The port authority received a $600,000 grant from the U.S. Environmental Protection Agency for a brownfield study in Trumbull County, Lown says, a portion of which was used to perform groundwater studies and other preliminary work at the sites.

Adequate roadways could only enhance the entire area and ultimately allow business to flourish, says Eric Fredenburg, president of Phoenix Tool Co. on Phoenix Road.

“We’re in a good location here and the township takes care of us,” he says. “We’re thinking about expanding, maybe even doubling our size.”

Fredenburg represents the third generation of his family to operate the business. His grandfather, another former employee of Van Huffel Tube, constructed the building in 1949 and expanded once, in 1968. The company is a small machine shop – it employs seven – but is one of the longstanding businesses in the Golden Triangle. “We do a lot of tooling for roll formers,” Fredenburg says. “Not too many people make tooling for tube mills. We’ve survived, and we’ve been on a steady ramp-up of production for five years.”

About half of his company’s market lies within a 50-mile radius of the shop, Fredenburg says, and serves large manufacturers such as Bull Moose Tube, Glunt Industries and Wheatland Tube. “We also send stuff to Nebraska, North Carolina and Michigan.”

Business has hit a plateau over the last three months or so, Fredenburg reports, but that’s only in comparison to a hectic spring and summer crammed with orders. “We’re indirectly tied to the oil and gas industry,” he explains, “but tube mills have other customers such as automotive and transportation, so you just never know. Business is steady. I’m not complaining.”

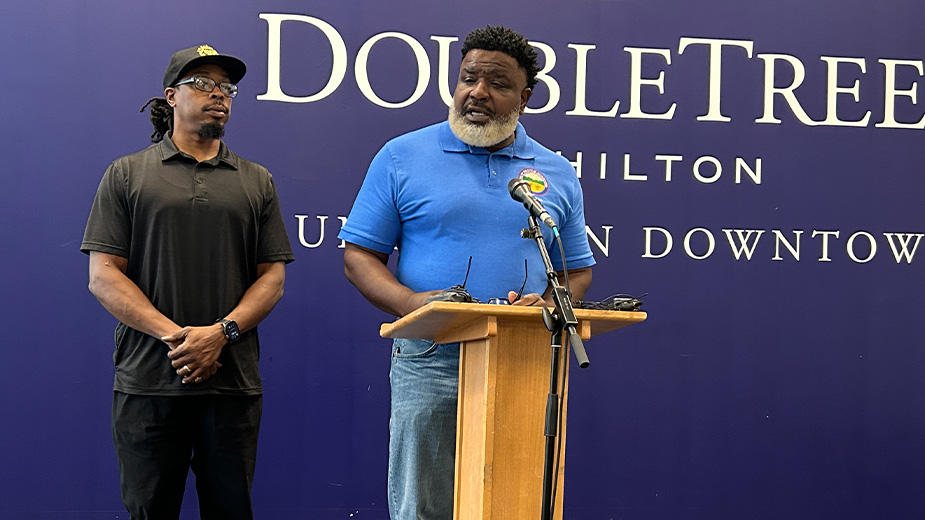

Pictured: Dale H. Gebhardt, president of Flex-Strut Inc.

Copyright 2024 The Business Journal, Youngstown, Ohio.