OH-Penn Expands Footprint, Focus on Apprenticeships

YOUNGSTOWN, Ohio – A five-county partnership that formed to focus on workforce needs of manufacturers in the northeastern Ohio-western Pennsylvania region is expanding both its mission and its geographic footprint.

Apprenticeships will be a primary focus of the newly formed Greater OH-Penn Manufacturing Apprenticeship Network, an offshoot of the Mahoning Valley Manufacturers Coalition. The initiative, funded by a nearly $3 million federal grant awarded in September, aims to help train 300 apprentices in 14 counties over five years.

The network will provide tools and resources to help small and medium-sized businesses “who might not have the bandwidth” to research and organize an apprenticeship program, says Jessica Borza, sector partnership coordinator for the network. “We’ll be providing technical assistance and in some cases even organizing group-sponsored apprenticeship models,” she explains.

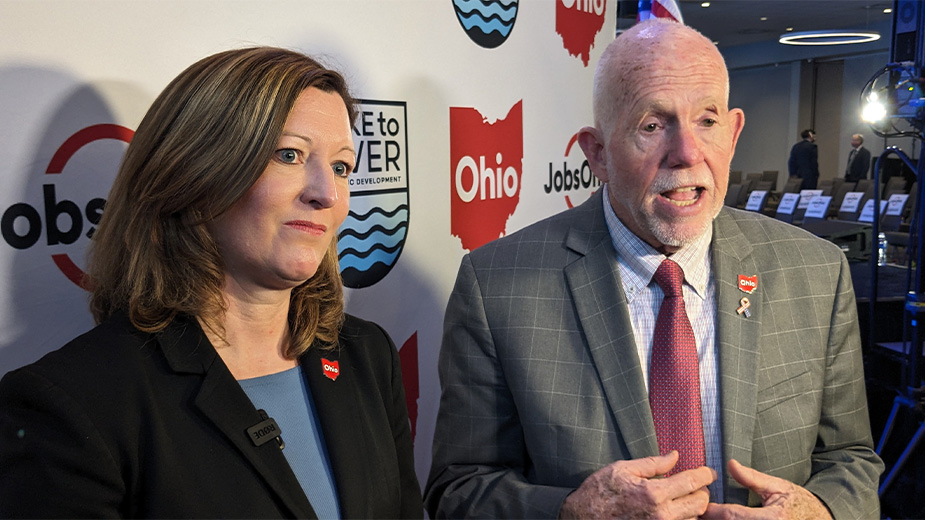

Borza is executive director of the Mahoning Valley Manufacturers Coalition, which represents manufacturers in Mahoning, Trumbull and Columbiana counties in Ohio. The coalition is one of two regional partners, along with Industry Partners of Mercer and Lawrence Counties of Pennsylvania, that comprise the OH-Penn Manufacturing Collaborative. The collaborative was formed through a four-year federal Workforce Innovation Fund grant that concludes in June.

The OH-Penn Manufacturing Collaborative has about 140 members, including 100 manufacturers, report Borza and Eric Karmecy, project manager for the Workforce Innovation Fund grant. “We’re working to bring more in every day,” Karmecy says.

Guided by a strategic action plan that was refreshed at the end of 2015, the OH-Penn Manufacturing Collaborative will continue to work to address skills shortages on a variety of fronts, Borza says.

Beyond the focus on apprenticeships through Greater OH-Penn, additional priorities for the manufacturing collaborative will include developing, strengthening and promoting career pathways and identifying and capitalizing on opportunities to share resources such as operating a shared training and innovation center. New members also will be recruited to join the coalition and Industry Partners of Mercer and Lawrence Counties of Pennsylvania, the other partner in the OH-Penn collaborative.

The manufacturing collaborative has “achieved quite a bit in the last 3½ years,” Karmecy says.

Over that time, the collaborative has worked with education and training centers to improve curricula to meet the demands of manufacturers. It has expanded the consortium in both states, and increased the number of employers using industry-recognized credentials to inform their hiring and promotion decisions, he says.

“We’ve increased enrollment in manufacturing training programs and the number of manufacturing-related credentials that individuals have received, and the number of workplace-based opportunities like internships,” Borza adds.

Across the various partner education and training institutions that offer manufacturing training, students earned 4,924 credentials during the past three years, Borza reports. Trumbull Career and Technical Center had 15 students enrolled in one of the two machining classes it ran in 2015 – the most ever – and Columbiana Career and Technical Center ran its first machining class in about four years with nine enrolled.

Improvements to curricula over the course of the Workforce Innovation Fund grant include updates to the precision machining programs for adult-program providers and the addition of an entry-level manufacturing readiness curriculum for adults.

The Greater OH-Penn network unites five sector partnerships representing manufacturers in the 14 counties. With the success of the Mahoning Valley Manufacturers Coalition, interest has grown, Karmecy says, and some organizations are replicating the coalition’s model.

“They’ve heard what was going on in the OH-Penn region in these five counties and they reached out to us to find out what the secret sauce was,” Borza says. “So we were able to share with them some things, like in the case of Mahoning Valley Manufacturers Coalition our bylaws and the way that manufacturers were the initial driving force to organize themselves and what the membership model looked like.”

When pursing the apprenticeship grant, bringing together the various regional sector partnerships “made sense,” Karmecy says.

“We’re excited about the opportunity to network with some of the other sector partnerships,” Borza continues. “It will give us an opportunity to tackle a new challenge and use a new solution to these workforce needs, which is apprenticeships. It’s something that all of the sector partnerships have identified as a potential solution.”

Along with Mahoning Valley Manufacturers Coalition and the Lawrence and Mercer Industry Partners, members of the Greater OH-Penn network are the Portage County Manufacturing Coalition in Ohio, representing Geauga, Portage and Ashtabula counties, and two Pennsylvania partners – the Advanced Materials and Diversified Manufacturing Industry Partnership in northwestern Pennsylvania and the Erie Regional Manufacturer Partnership.

“We strongly support any initiative that promotes workforce development in the manufacturing industry,” remarks Jon DeArment, president and CEO of Channellock Inc. in Meadville, Pa., which manufactures hand tools. “Our competitiveness depends greatly on the skill set of our workforce.”

Depending on the required skill level, finding qualified workers is difficult, points out DeArment, who serves on the steering committee for the five-county Diversified Advanced Manufacturing Industry Partnership. Entry level is “somewhat easier” because the company has a strong training program in place to address specific skill needs at that level, and has seen success with employee referrals for the past 18 months.

“We do find that the more advanced the skill set required is, the harder it is to find people,” he remarks.

Jim Rutkowski Jr., general manager at Industrial Sales & Manufacturing Inc. in Erie and secretary of the Erie Regional Manufacturer Partnership, points to continued need for welders, CNC programmers and machinists, robotics operators and maintenance workers.

“If you look at the demographics, people in the manufacturing workforce are retiring at a faster clip than we can replace them,” he says. Like many manufacturers, Rutkowski argues school systems have “kind of failed” at producing students for manufacturing and instead focused on preparing them to go to college.

The Erie partnership, which launched about a year ago, is one of the organizations that modeled itself on Mahoning Valley Manufacturers Coalition and OH-Penn. “We looked at some of their best practices but did our own thing,” Rutkowski says. “We built ours around what we were doing.”

The Erie partnership combined its 2015 Manufacturing Day outreach to students with a manufacturers summit similar to OH-Penn’s summit a few years ago, Borza says. “They had all kinds of exhibits and it was really cool,” she remarks.

The partnership’s 2015 Manufacturing Day event attracted more than 1,500 students, Rutkowski reports.

Early in 2016, the Greater OH-Penn network will begin seeking manufacturers who are interested in adopting apprenticeships or reviving programs they had previously, Borza says. “We have built in some grant resources to incentivize manufacturers to work with us to establish or revive those programs and we’ll be providing a lot of technical assistance and helping manufacturers to make it more accessible than it seemed in the past,” she says.

“The biggest thing is trying to get more manufacturers to recognize that this grant exists and there’s going to be resources there to help streamline the process,” Karmecy adds. “The grant’s going to give us not only resources to help offset their costs for training but also help us give boots-on-the-ground support and staff to walk them through some of the paperwork process.”

Copyright 2024 The Business Journal, Youngstown, Ohio.