Additive Manufacturing Needs Skilled Workforce, Economic Summit Told

YOUNGSTOWN, Ohio — Many people in the community don’t understand the capabilities of additive manufacturing, a point sometimes lost on those who are “so invested in the space,” said John Wilczynski the executive director of America Makes.

Wilczynski was among the participants in a panel on additive and advanced manufacturing held Tuesday as part of the daylong virtual Lordstown Economic Recovery Initiative’s Regional Economic Diversification Summit.

Other participants included Barb Ewing, CEO of Youngstown Business Incubator, who served as moderator; Lonnie Love, corporate fellow with Oak Ridge National Laboratory; David Sipusic, executive director, YSU Excellence Training Center; and Zachary DiVencenzo, president of Juggerbot 3D.

In introductory remarks, U.S. Sen. Sherrod Brown, D-Ohio, complained that the national media paints the Mahoning Valley “in broad strokes,” rarely mentioning the advanced manufacturing going on at YBI and America Makes, research being done at YSU or workforce development at Eastern Gateway Community College.

Federal investments are needed to ensure workers are equipped to drive Ohio’s success through the 21st century, Brown said.

“Ohioans know how important manufacturing is to our economy. Our workers are among the best in the world,” he said. “We know that advanced manufacturing is vital to our state’s and this region’s local economy.”

America Makes is positioning itself as an organization to bring the community together to accelerate the adoption of additive manufacturing, Wilczynski said.

“A big part of what we’re all realizing, and many knew, is no matter how much technology that we develop, as a region or as a nation, if we’re not developing the workforce and growing the companies that can take advantage of this, we’re not doing the technology justice and ultimately not getting what we can out of the technology,” he added.

“The YSU Excellence Training Center will be a one of a kind education, innovation and research facility,” Sipusic said.

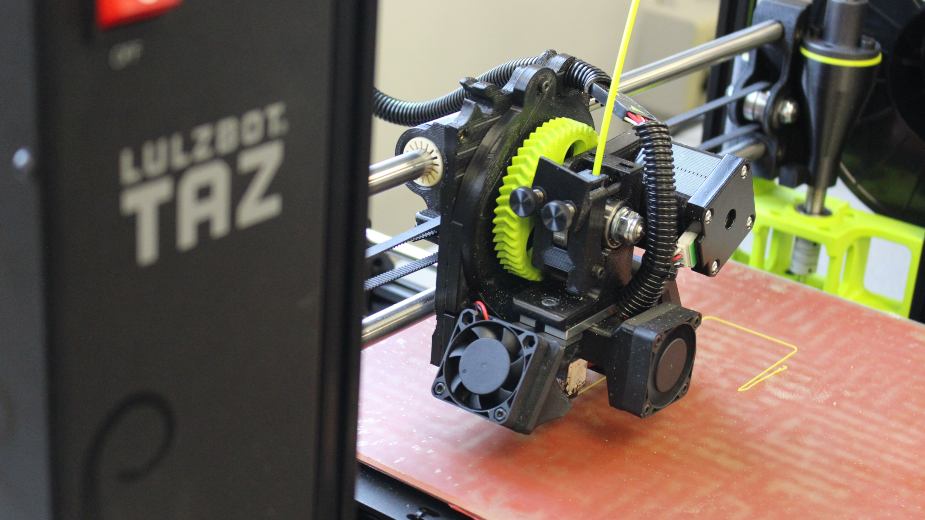

“It’s going to be focused on the acceleration and development of the 21st century workforce,” he said. Projected for completion in March 2021, it will offer access to a broad range of advanced manufacturing assets, including additive manufacturing.

Oak Ridge, which provided early support for America Makes, has been involved with additive manufacturing for a long time because of the technology’s potential for reducing the carbon footprint, Love said.

“You really have it all going on in that area. There’s this amazing ecosystem that to me is second to none in terms of additive,” he said.

Oak Ridge’s core strengths are in materials and the laboratory has “a lot of the building blocks for additive” – including supercomputing capabilities for modeling and simulations and using neutrons for validations – “that we really are wanting to leverage, working side by side with America Makes to provide access to all of these tools,” he said.

The tool and die industry, which he described as “low hanging fruit,” presents “a tremendous opportunity” for Youngstown to help reshore work that has gone overseas, he said.

Juggerbot is developing equipment that “has the look and feel of traditional manufacturing equipment that tool and die makers and machinists are accustomed to,” DiVencenzo said.

While people think of 3D printing’s capabilities to manufacture an end part, they “completely overlook” that 3D printing can be used to produce the tooling that can be used to manufacture the final part.

“One industry that’s being overlooked drastically is the casting industry,” he said. “And for low volume production, 3D printing is a perfect alternative for manufacturing tooling.”

He also talked about the potential for using it to manufacture non-pneumatic tires for autonomous vehicles, as well as for thinking about additive manufacturing as “a completely new manufacturing vertical from start to finish.” Manufacturing engineers graduating from YSU and other schools don’t know how to optimize the process, he warned.

“We need more people thinking about new products, new technology doing research that can be commercialized. We need every player on the field,” Ewing said.

Engaging children, including those in socially and economically disadvantaged communities, is “incredibly critical,” she added.

“This is really an opportunity for us to rethink business as usual in the Mahoning Valley. Engage our students and our young people in this really exciting new technology and that can’t happen young enough,” she continued. “Every kid knows how to program. We’re not yet to the point where every kid knows how to 3D print.”

The field is “still a pretty sexy space” with “a lot of opportunities to engage kids who otherwise would not be thinking about a STEM field,” she added.

Copyright 2024 The Business Journal, Youngstown, Ohio.