Petrochemicals Hub? Storage, Distribution Needed

YOUNGSTOWN, Ohio — The United States stands to produce more than 54 billion pounds of polyethylene per year by 2020, thanks to the more than a 30-year supply of ethane gas in the Marcellus and Utica shale plays in Pennsylvania, Ohio and West Virginia.

So finds Petrochemical Update’s Market Outlook 2018.

Indeed, production of polyethylene – a base ingredient found in countless plastics products – is expected to exceed by far the domestic demand and fuel the projected growth in exports driven by global demand from customers that manufacture pipe, performance films and packaging.

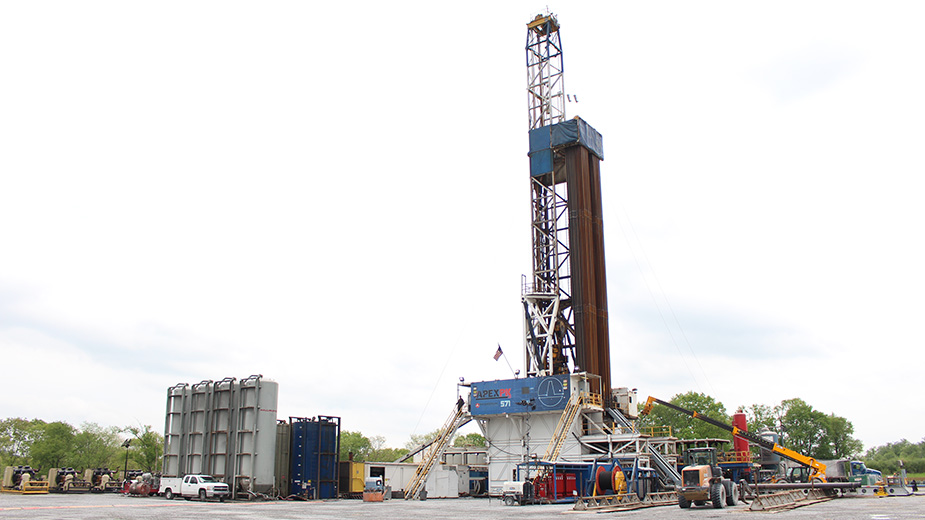

Ethane, a natural gas liquid processed in petrochemical “crackers” to produce polyethylene, is found in abundance in the Utica and Marcellus shales.

According to the Energy Information Administration, or EIA, total natural gas production from the Northeast today stands at 20 billion cubic feet per day. This is projected to double in the next 35 years, the report says, and account for 40% of total gas production in the United States.

Today, the United States manufactures 25% of the world’s natural gas liquids, and the Northeast produces 25% of U.S. production.

That’s led to new investments in the ethylene market, especially in the Gulf Coast region and, more recently, evidenced by Royal Dutch Shell’s decision last year to move forward on construction of a $6 billion ethane cracker plant along the Ohio River near Monaca, Pa.

“The recent relative stability in the oil, coupled with a renewed sense of optimism on long-term global demand growth, is spurring a new round of project announcements and activity,” states Joseph Chang, global editor ICIS Chemical Business, in the report.

Such demand and resources place Pennsylvania and Ohio in an ideal position for growth in the petrochemicals and plastics market, the report says. Citing an IHS Market analysis, the white paper notes that demand for 73% of polyethylene and 67% of polypropylene in the United States and Canada lies within a 700-mile radius of southwestern Pennsylvania.

“The advantages for the Appalachia chemicals and plastics industry are huge,” Martha Moore, senior director of economics and policy analysis at the American Chemical Council, says in the report. “The area has proximity to abundant NGL resources in the Marcellus/Utica and Rogersville shales,” as well as being near manufacturing centers in the Midwest, the East Coast and Canada.

Since 2010, construction of 310 petrochemical projects valued at $185 billion have been announced and that can be attributed in part to the enormous cache of shale gas found in the Northeast. These projects include factories, expansions and restarts of plants that closed during the recession. The investment, the American Chemical Council estimates, would translate into 821,000 permanent jobs nationwide by 2025.

The investment by Shell could spur a regional economic ripple effect that would produce 100,000 permanent jobs, including 25,700 new plastics manufacturing and chemical positions, the council estimates. Another 43,000 jobs would be created through supplier industries, while 32,000 spinoff jobs could be created in communities where workers spend their wages.

Still, significant challenges remain in developing Appalachia into a petrochemicals hub, according to the report. The most glaring is the absence of a large storage and distribution system in the region for NGLs, which are regarded as a fundamental component in sustaining a chemical manufacturing industry.

“Without existing infrastructure, it’s difficult for the region to attract NGL consumers such as manufacturing facilities,” the chemistry council’s Moore says. “At the same time, the absence of an established NGL customer base makes it difficult for pipeline developers to secure loans.”

Currently two companies, Energy Storage Ventures and Mountaineer NGL Storage LLC are in the early stages of developing NGL storage caverns in the Appalachian region.

Another development needed to support the industry is an additional 500 miles of pipelines along the Ohio River, the chemistry council says. Meantime, the region’s workforce would require new training programs to learn the skills needed to support a petrochemicals hub.

Aside from the lack of infrastructure, the Appalachian region lacks the flat topography that petrochemical complexes find attractive for sprawling developments. To help address this, the Ohio River Corridor Team was formed to identify sites of 1,000 acres or more that could accommodate a large petrochemicals operation. Among them are sites in Weirton and Newell, W.Va. Smaller sites along the river such as Mingo Junction and Marietta in Ohio could support manufacturing operations.

“While the region with its ample and reliable supply of ethane is primed for the emergence as a second major petrochemical manufacturing hub in the United States,” the report concludes, “it faces the challenges of rapidly developing a workforce, as well as storage and pipeline infrastructure to fuel such development.”

Copyright 2024 The Business Journal, Youngstown, Ohio.