T. Bruce Scores Big in Heavy Plate Manufacturing

WEST MIDDLESEX, Pa. — Patrons passing by or filing into Heinz Field in downtown Pittsburgh are likely to notice the bright yellow supports outside that buttress the upper decks.

Each set of columns – 18 in all positioned around the stadium – has four metal beams that converge at a single point and fan outward like fingers. The design creates the needed structural and engineering effect that makes it possible for those upper stands to hold the thousands of Steelers fans at professional football and other events.

“We built those. And we built the pod bases that they sit on,” says Bob Jackson, plant manager at T. Bruce Sales Inc. in West Middlesex, Pa. The company, established in 1952, manufactures and fabricates mostly heavy-plate steel components used for industrial purposes, especially in mining and steel.

The company’s site consists of 90,000 square feet of manufacturing space across several buildings. It leases another 30,000 square feet to other operations.

All of the tools of the machining trade are here: CNC milling equipment, plasma cutting machines, lathes, welding, grinding, bending, fabricating and a Farley LaserLab cutting machine.

“It begins with a request for quotations,” Jackson says. Once the company receives the request and design, it ascertains what material and how much would be needed to complete the job. “We’ll estimate the hours, submit the quote, and if we’re fortunate enough to get the bid, we’ll start purchasing the material,” he says.

“We’re an almost completely self-contained business,” Jackson says. “We bring the material in. We burn it to size. We fabricate and form. We have big CNC milling machines, lathes, stress-relieving furnaces, blast-cleaning and painting.”

Some of the smaller and specialty work, such as rubber lining and silver plating, is subcontracted to other shops, he says, but most of it is “kept in-house.”

Riise and T. Bruce most recently designed and manufactured a materials-handling system for Nucor (Steel) Corp. in Arkansas. “That was a custom-designed project,” he says.

“When we do a Riise project,” says Jackson, “our guys will go out and see what the customer wants and they totally design it to meet their needs.”

Once the design is completed, the drawings are sent to T. Bruce, which builds the system. “We build it, and we can do complete turnkey, depending on what the customer wants,” Jackson says.

The company details its materials through the use of computer-aided design and 3-D design, which helps T. Bruce fitters and assemblers with the manufacturing process. The information is programmed into a computer and delivered electronically to the production equipment on the shop floor. “We have automated burning equipment,” Jackson says, including the Farley laser, which doubles as a heavy-plate cutting machine and a 12-change tool holder that is programmed to drill.

A sizeable portion of T. Bruce’s business is done with the mining industry, a sector of the economy that is undergoing difficult times at the moment, Jackson says.

“That’s the soft spot,” he says of the mining industry, saying that the Obama Administration’s policies haven’t helped domestic coal production. “As soon as he was re-elected, our business dropped off like a boat anchor as far as mining goes,” Jackson states.

According to the U.S. Energy Information Administration, national coal production is projected to decline to 943 million short tons this year from 997 million short tons produced in 2014.

Some business from mining still trickles in, but the company has sufficiently diversified to withstand weak spots, he notes. On the shop floor in late March, for example, the company was machining new components for an underground mining conveyance system. In another section of the campus, press operator Dean Piatt is forming a lip around the interior hole of a large, heavy stainless steel disc used for rendering equipment in the food-processing industry.

“It’s about a 30-inch inside diameter,” Piatt says of the piece as he prepares to work the 1,700-ton press – the largest in the company’s shop.

Piatt is in his 18th year with the company, which he joined as a laborer and has worked his way to machine operator. “I was in the machine shop,” he says, “ran the burning tables a little bit, and now I’m out here.”

Jackson says that T. Bruce, which employs about 50, finds it beneficial to hire those with a strong work ethic and a willingness to learn. “We like to grow our own here,” he says. “We promote people from within. It just works better that way.”

Jackson says his company’s continued investment in its CNC machining equipment has allowed it to remain competitive in its markets. As the mining industry boomed over the last decade, Jackson says, it was imperative that the company reinvest in new automated machine centers to ensure more precision and production speed.

Today, two CNC five-axis horizontal machining centers do the work of several manually operated horizontal mills. “I used to have eight manual machines,” he remarks. “I have one now.”

Aside from the CNC equipment, T. Bruce Sales has two thermal-stress-relieving furnaces on its 25-acre campus, used to relieve stresses on new welds. Once a component is fabricated, it’s cleaned through a shot-blast process and then painted. Workers on this March morning were busy painting trusses that will be used for noise-suppression housing to contain compressors in the oil and gas industry.

The company ships its parts throughout the United States, Jackson says. Many customers are engineering companies contracted by steel manufacturers, mining companies and many other industries.

“We’re pretty well diversified, so we don’t have any one customer that kills us,” Jackson says. “We’re a fully equipped job shop. We’ll work 24/7 depending on the project.”

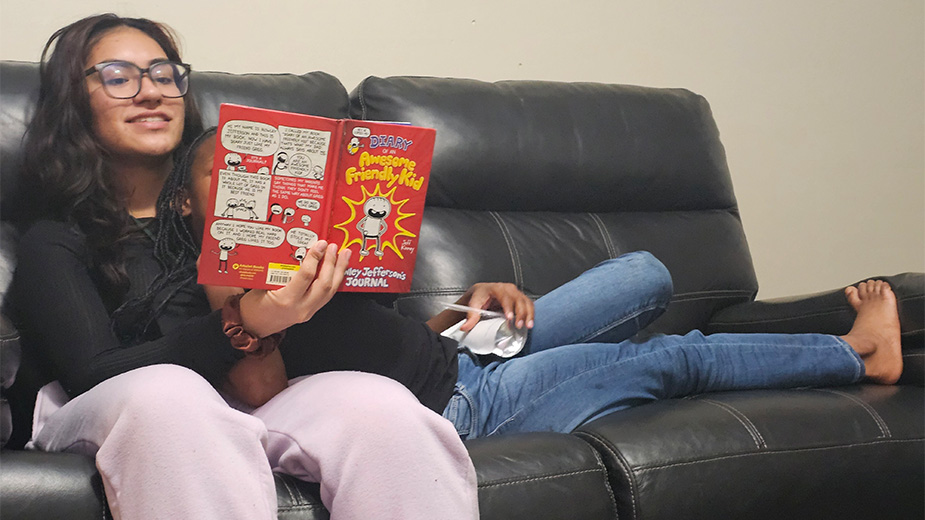

PICTURED: Bob Jackson, plant manager, stands beside a newly manufactured component used in the mining industry.

Copyright 2024 The Business Journal, Youngstown, Ohio.