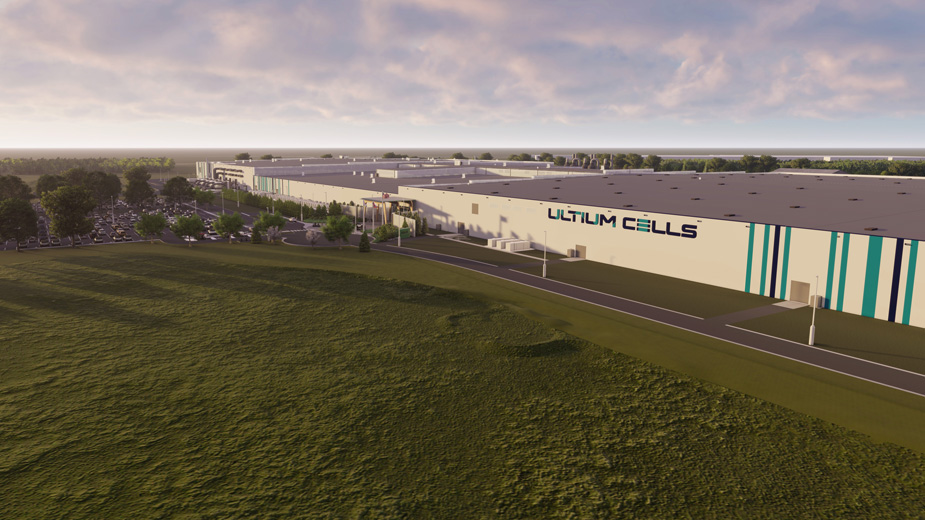

Ultium Cells CEO: ‘It’s About People’

LORDSTOWN, Ohio – The president and CEO of Ultium Cells LLC said Wednesday that a key component in making its $2.3 billion electric-vehicle battery plant a success will be its workforce.

“At the end of the day, it’s about people,” Kee Eun told attendees participating in the first Explore the Valley Virtual Career Fair hosted by Youngstown State University’s Center for Workforce Education & Innovation and JobsOhio. “Our core interest is to attract good, talented people.”

The CEO’s brief remarks come as Ultium – a joint venture between General Motors and Korea-based LG Energy Solutions – charges toward completion of its nearly 2.8 million square-foot battery manufacturing plant along Tod Avenue. The sprawling factory will supply batteries to GM’s new lineup of electric vehicles, beginning with the Hummer EV and the Cadillac Lyriq.

Eun said that his relationship with GM goes back more than a decade, when he was selected by his then-employer LG Chem to work with Detroit automakers to gain a foothold in the nascent electric-vehicle market.

As LG’s program manager in Detroit, Eun established LG Chem’s battery manufacturing plant in Holland, Mich.

“We started with the plug-in hybrid, the Volt, in 2009,” Eun said. The relationship with GM continued as the two companies partnered on new battery technology, providing the power source for GM’s second-generation all-electric passenger vehicle, the Bolt. “It runs over 230 miles per charge,” he said.

In 2019, GM and LG Chem announced it would create a joint venture to build a $2.3 billion EV battery manufacturing facility near GM’s former Lordstown Assembly plant.

In the process, LG Energy Solutions, a spinoff from LG Chem, was created to serve as GM’s partner in the new venture – now named Ultium Cells LLC. Eun was named president of the company in 2020.

Construction on the plant is scheduled for completion by the end of this year and should become operational by the middle of 2022, said Thomas Gallagher, Ultium’s chief operating officer.

“We’re excited about the work underway and construction at the facility,” he told participants. Once fully operational, the plant is expected to employ more than 1,100 workers.

The new plant is poised to make “millions” of cells in the future, he said, as the auto industry migrates to all-electric vehicles. Ultium’s new factory, for example, will include amenities such as EV charging stations and access to “show” vehicles to demonstrate Ultium’s performance.

At present, Ultium is identifying opportunities to build its team in Lordstown, Gallagher said.

David Titmuss, a technical specialist at Ultium and a 26-year veteran of GM who began his career with internal combustion engines, said the manufacturing process in battery production is much different than traditional automotive work.

“I’ve had this opportunity over the last year to learn a whole new business, a whole new process,” while at the same time apply LEAN manufacturing strategies he learned while at GM, he said.

A major difference between auto production and battery manufacturing is speed, Titmuss said. “There are millions and millions of cells to be produced. That’s going to continue to keep growing.”

Battery production involves much more automation at higher speeds than assembly line work, Titmuss added. “There’s a lot of inline inspection, a lot of high-technology camera work,” he said, as well as charge and discharge operations.

Hands-on electrical training, robotics, as well as tooling skills are important in these jobs, Titmuss said.

More importantly, Ultium’s growth arrives at an ideal time in the market as automakers begin the transition to all-electric platforms – a transition that is happening faster than anyone had anticipated.

“In 2020, the market penetration of EV globally was about 3%,” said Germanus Woo, Ultium’s planning director. By 2025, that number is expected to hit about 13%, he said.

The rest of the market represents enormous growth potential, Woo noted. He said President Biden’s efforts to reduce the U.S. carbon footprint and electric-vehicle adoption provides a healthy incentive for additional growth.

“What excites me in the United States is all the movement with a variety of products – trucks, crossovers, cars, SUVs – a full range of products that appeal to various customers,” Gallagher said.

“We have a growing EV market with ideal circumstances in entering this space,” Gallagher says of Ultium.

Pictured: The Ultium Cells LLC battery cell manufacturing facility in Lordstown, Ohio will be about the size of 30 football fields and will have annual capacity of more than 30 gigawatt hours with flexibility for expansion.

Copyright 2024 The Business Journal, Youngstown, Ohio.