Ursa Major Awarded Follow-on Contract by America Makes

YOUNGSTOWN, Ohio – Ursa Major has secured a follow-on contract with America Makes to qualify its copper additive manufacturing process for hypersonic flight.

The contract represents a $5 million investment. America Makes will contribute $4 million, and Ursa Major will provide the remaining $1 million.

Over the next 21 months, Ursa Major will use the funds to transition its innovative copper additive manufacturing capability into flight-qualified hardware for its America Makes customers: the National Center for Defense Manufacturing and Machining and the Air Force Research Laboratory based out of Wright-Patterson Air Force Base in Dayton, Ohio.

Ursa Major will install a Velo3D Sapphire XC Metal 3D Printer to qualify its copper additive manufacturing process on a full-scale production platform. Once qualified, it will print thrust chambers to support both Hadley and Draper flight engines.

“Ursa Major continues to be at the forefront of implementing additive manufacturing in aerospace and defense programs,” said John Wilczynski, executive director of America Makes. “We are excited to partner with Ursa Major in demonstrating the impact additive manufacturing can have in solving supply chain and manufacturing challenges within our defense industrial base.”

Ursa Major and America Makes began their partnership in 2021 with the establishment of the Ursa Major Advanced Manufacturing Lab in Youngstown. In the first two phases of the contract with America Makes, Ursa Major engineers developed an additive manufacturing process capability for NASA’s high conductivity and high strength copper-chrome-niobium alloy, GrCop-42, and produced prototype thrust chambers for the vacuum variant of the Hadley liquid rocket engine. Continuing through mid-2024, the collaboration’s focus shifted from prototype printing to the production and qualification of engine hardware.

“America Makes has been a trusted partner for the past three years, allowing Ursa Major to create high-quality and scalable systems in our Advanced Manufacturing Lab in Youngstown, Ohio,” said Nick Doucette, chief operations officer for Ursa Major. “This next step will establish Ursa Major as a scalable and trusted manufacturing partner in the defense and aerospace sector while maturing production readiness for our Draper and Hadley rocket engines.”

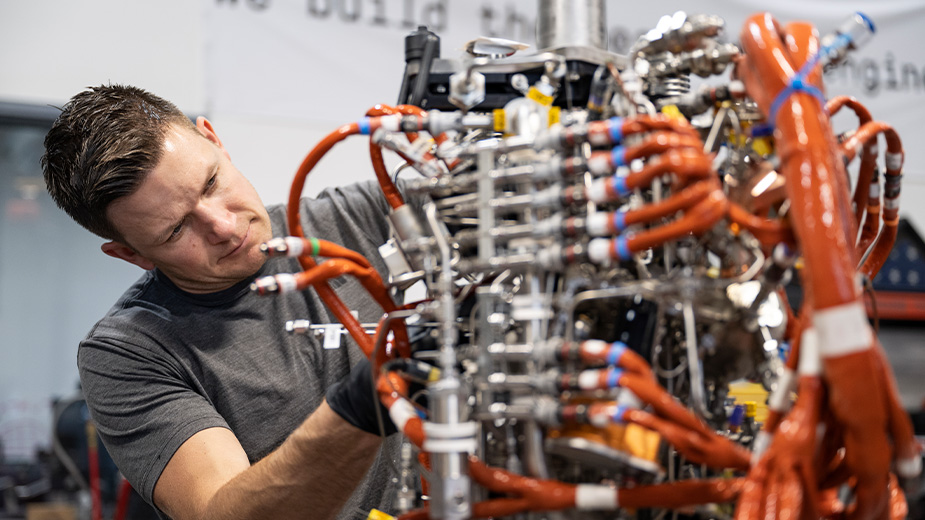

Pictured at top: An Ursa Major technician works on a Hadley engine. (Ursa Major)

Published by The Business Journal, Youngstown, Ohio.