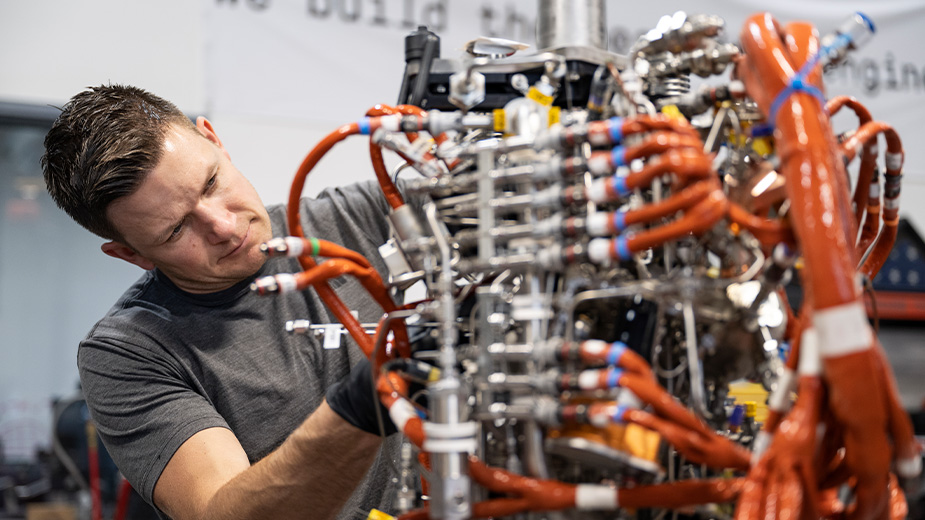

Ursa Major Plans $14.5M Expansion in Boardman

YOUNGSTOWN, Ohio – Ursa Major, a Denver-based company that manufactures rocket propulsion components, is expanding its Mahoning Valley footprint with a $14.5 million investment.

The company plans to establish a new research-and-development center in Boardman to advance additive manufacturing and materials development technology for liquid rocket engines and solid rocket motors.

Ursa Major, which has its local operation based at the Youngstown Business Incubator’s Tech Block Building No. 5, expects to have renovations completed in the next month or two on space it is leasing at 8469 Southern Blvd., Nick Doucette, chief operating officer, said during a phone interview Wednesday. The building, a former bus depot, is “in pretty good shape,” he said.

Ursa Major is leasing approximately 10,000 square feet of the building.

Ursa Major began its relationship with YBI and America Makes in 2021, when it established its advanced manufacturing lab at YBI’s TBB5. The company has outgrown its existing space at YBI but expects to maintain its space there, at least for the time being, Doucette said.

The expansion will bring the company’s local employment to 18 over the next few years, up from three, according to a news release from JobsOhio, which provided a $4 million R&D grant.

“The new R&D center in Youngstown takes advantage of Ohio’s manufacturing heritage and uniquely skilled workforce to advance manufacturing in service to our national security,” Ursa Major CEO Joe Laurienti said in the release. “Raw material access, supply chain, and a vibrant additive manufacturing ecosystem as a result of the America Makes program make Youngstown an ideal home for this center.”

So far, the Youngstown operation has had “zero issues” attracting talent, and Doucette said he anticipates that as the facility’s momentum and recognition grow, attracting talent will get even easier. The available talent pool includes students from Youngstown State University and Penn State University, which has “an amazing materials engineering program,” he said.

“I would argue that our current team is our most productive at the company,” he added. “They get more work done than anybody. It’s crazy.”

Liquid rocket engines and solid rocket motors power platforms that are essential for America’s security, including high-performance munitions, hypersonic weapons, in-space propulsion systems and space launch, according to the release. Ursa Major is expanding its R&D efforts to meet a rapidly growing portfolio of U.S. Department of Defense development contracts.

Doucette acknowledged Wednesday that, had he been asked a few years ago “if we’d be having this conversation today,” he would have responded that he didn’t know. But now he is “extremely bullish on what the future holds” in terms of growing the “center of excellence” locally.

“It’s been insanely productive,” Doucette said. The Youngstown center has achieved “industry-leading development timelines for propulsion hardware. So it’s paid off.

“Ursa Major’s R&D center plans in the Mahoning Valley represent Ohio’s strong aerospace and manufacturing legacy and how this state is driving the future of how things are made in America and worldwide,” said JobsOhio President and CEO J.P. Nauseef. “Innovation from Mahoning County is rapidly advancing additive manufacturing technology, and Ursa Major’s investment is an example of how that attracts extraordinary companies.”

The new center in Boardman, which will accommodate several laser powder bed fusion 3D printers, will accelerate new material development and qualification processes for aerospace applications of additive manufacturing, according to the JobsOhio release. That includes developing metallic alloys for solid rocket motors and development of copper and nickel alloys for liquid rocket engines.

Acceptance of 3D printing as a manufacturing process has grown by “leaps and bounds” in recent years, Doucette said. Printing parts is a “way more controlled” process than casting, which is “very archaic” but widely accepted.

“When it comes to our liquid rocket engines and their aerospace and space launch applications, printer hardware and the processes and process controls that we’ve put around it are fairly accepted,” he said. The solid rocket motor industry is beginning to accept additive manufactured hardware and is having the same conversations that the liquid industry had a decade ago.

Doucette did not offer a specific timeline for reaching the jobs creation numbers. The number of employees will depend on how operations are scaled and “how quickly we commission machines,” he said.

“It’ll all be matched on how our production grows with us,” he said.

Pictured at top: An Ursa Major technician works on a Hadley engine. (Ursa Major)

Copyright 2024 The Business Journal, Youngstown, Ohio.