YBI Acquires ‘Revolutionary’ Additive Technology

YOUNGSTOWN, Ohio — When he was a manufacturing engineering student, XJet CBO Dror Danai said you are taught not to design things that cannot be made later on. With the XJet Carmel 1400C, ceramic 3-D additive printing machine now operating at the Youngstown Business Incubator, he said that is no longer a concern.

While the XJet Carmel 1400C hummed in the background, YBI staff, the innovators from XJet and other partners celebrated the fruition of bringing the groundbreaking additive manufacturing technology to the Youngstown area.

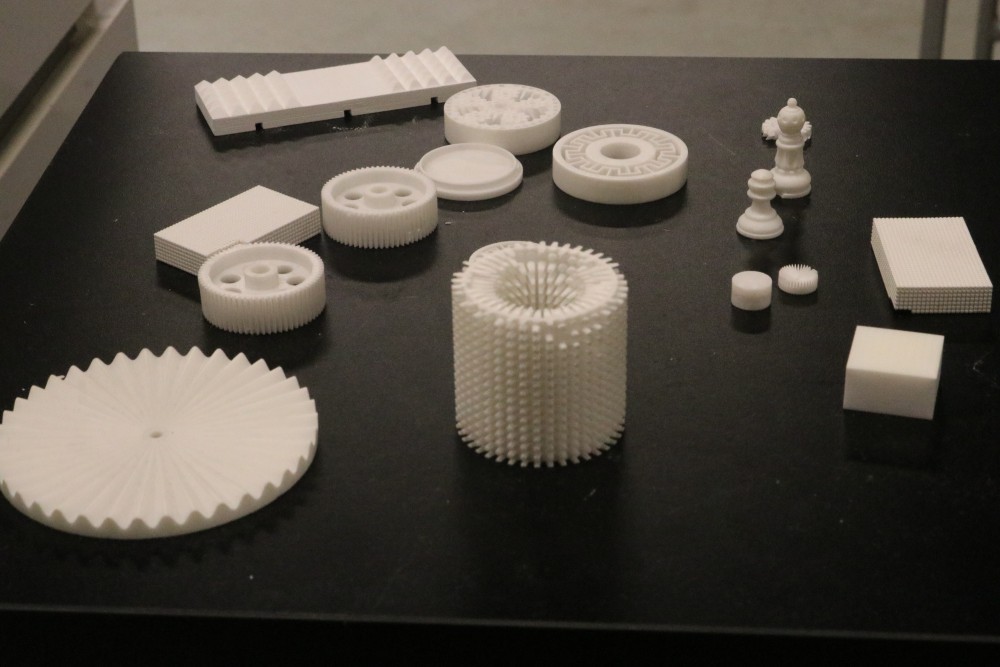

The YBI announced Wednesday it has completed the purchase agreement for the machine, which it says leverages revolutionary NanoParticle Jetting (NPJ) technology to create additive manufactured items out of ceramics. Created by X-Jet, an Israeli company, the technology is capable of creating small, intricate, highly specialized ceramic items. Earlier efforts in additive manufacturing have involved polymer and metal materials, not ceramics.

YBI was the first to have the machine in North American, which partnered with XJet to help launch the new technology and get their new machine operating here. Despite a few growing pains and COVID-19 slowing their plans, the purchase agreement is now final between YBI and XJet.

“I’m confident with this kind of collaboration we can continue to do great things, continue to change the world,” said XJet CEO Yair Alcobi.

Danai said in choosing a place like Ohio and a company like YBI, Xjet would like to bring a shift into ceramic additive manufacturing throughout the county. He credits YBI with keeping the project moving forward even with the challenges they faced.

“Everybody knows why ceramic is so important, but with ceramics it is difficult to create different shapes,” Danai said. “This is why 3-D printing makes a difference, because now you are unlimited with the geometries that you can make.”

Resistant to heats and certain chemicals, the ceramic products are not susceptible to the pressures of wear and are able to insulate in electrical applications. Danai said there are applications that can be done only with ceramics. He sees additive manufacturing as the start of the next industrial revolution because it can be used to create complexity without added cost.

The machine prints items with moving parts in one shot. Danai said the 3-D printing technology is aided by another jetted support material, that is used as a space holder and then will disappear because it is water soluble. He told the crowd about an innovative piston for a European Chaos car recently created with an Xjet machine.

“This shows you the opportunities that additive manufacturing is opening for creative for people, it allows them to think about a few things that were impossible before,” Danai said.

The machine at YBI is now ready to begin taking on more commercial outside projects.

YBI reports the ceramic 3D printing market is expected to grow seven-fold by 2032, reaching $400 million. The technology can be used to create parts for vehicles, medical, industrial and consumer products.

YBI CEO Barb Ewing said YBI staff were approached by five or six different people interested in creating something with the technology while attending the recent Ceramics Expo event.

The XJet Carmel 1400C machine came to YBI following a 2017 trip to Israel sponsored by the Thomases Family Endowment of the Youngstown Area Jewish Federation. YBI, which has partnered with the YAJF since its inception, and Youngstown State University President Jim Tressel were among those who made the trip.

“We’ve been partnering with YBI since 2013,” said Lisa Long, the financial resource development director and administrator of the Thomases Family Endowment. “This trip in 2017 was third times a charm. We had been trying some business development missions and we just struck gold with this one… It was the right people at the right time.”

The Thomases Family Endowment has granted the program to bring the new technology to the Youngstown area more than $127,000, one of the foundations largest outside investments in 2021.

“In our realm we call it I-YBI,” Long said. “We’re so passionate about Youngstown and we’re so passionate about Israel,” Long said, noting Israel is on the cutting edge of technology, as is the Youngstown area, so it made sense for the foundation to help make this happen.

Tressel said the trip included meetings with six companies and five universities.

“This is one of the great things that have come [from this trip],” Tressel said. “This is going to be huge for our country, our state and for our region.”

John Wilczynski, executive director of America Makes, noted that over the past 10 years they have learned the importance of bringing new additive manufacturing technologies here and utilizing them to create regional opportunities.

“We’re very excited, very proud of the team that came together to make all this possible,” Wilczynski said. “But ultimately, we’re most excited about the opportunity we have over the coming years. What we hope to be celebrating in the coming years is the success of this and how we can use it in new fields.”

According to Ewing, the multifaceted machine will be used for work with their portfolio companies already working with YBI, as well as bringing new business partners to YBI.

“We are well on our way hoping to commercialize this machine in the United States and we are so very proud of it,” Ewing said.

Pictured at top: Myra Benedikt, Youngstown Area Jewish Foundation past board president; Lisa Long, financial resource development director with the Youngtown Area Jewish Foundation; Dror Danai, Xjet CBO; Barb Ewing, CEO of the Youngstown Business Incubator; James Dascenzo, YBI executive committee chairperson; Yair Alcobi, Xjet CEO; YSU President Jim Tressel; John Wilczynski, executive director of America Makes; and Bonnie Burdman, executive director of community relations/government affairs at the Youngstown Area Jewish Foundation.

Copyright 2024 The Business Journal, Youngstown, Ohio.