YBI Welcomes 7th 3-D Printing Startup

YOUNGSTOWN, Ohio – Staff Sgt. Adam Bavuso had a problem.

The gate he used to keep his four children – all under age six – from falling down the stairs kept breaking. More accurately, his children, who had no awareness of their own safety, kept breaking it.

“Getting parts from the manufacturer was a huge pain,” Bavuso recalls.

So he collected the broken pieces and printed a replacement part on his newly bought 3-D printer.

“It’s been on the wall ever since,” he says matter-of-factly. “The [printed] part’s lasted longer than the manufacturer’s parts.”

He estimates it took one hour and about $1 worth of material to produce the part himself.

Bavuso bought his printer from Ben Kilar, a former Marine and native of Hubbard who was attending the University of Alabama in Huntsville. When Bavuso’s father expressed an interest in purchasing a 3-D printer, the two decided it would be better to build their own.

“He got all the mechanicals, the frame and everything done, and he sent it down to me. And I got all the printing action working,” Kilar says.

What the two came up with was the device that would become so important to Sgt. Bavuso and his family.

“Many, many sleepless nights making it perfect,” says Kilar.

The CreatorBot 3D comes with Wi-Fi connectivity, a magnetic build plate and a 3.5-inch touch screen display. But the feature that makes it really stand out is its build volume.

“We can actually print 12x12x18 inches,” Kilar says.

His printer costs $2,100 while comparable models usually run in the $6,500 range.

The printers can be purchased fully assembled or as do-it-yourself kits. So far he’s sold and shipped more than 100 printers to customers as far away as Australia, Saudi Arabia and South America.

“The frame for the printer is made out of extruded aluminum. It’s very strong and robust,” says Kilar. “I ship them all around the world and they survive.”

Bavuso’s printer had to go only as far as Colorado Springs, Colo.

“The way he had it set up, the assembly and functionality was simple,” says Bavuso, who had no experience with 3-D printers before his purchase.

Another benefit, he says, is that all the software is open sourced and all of the designs for the parts are available online.

“So if you want spare parts you can print them and keep them in a box like I did,” Bavuso says.

In fact, the only drawback he’s found is with the print plate, which must be adjusted manually.

It’s a problem Kilar has solved for the next version of his printer. The print head contains a sensor that uses 16 points on the print plate to keep everything level.

To demonstrate, Kilar tilts the entire printer 45 degrees and it continues to run smoothly.

After he moved back home, bringing with him more confidence in his product, Kilar sought help from the Youngstown Business Incubator, at the time home to six additive manufacturing startups.

His company is called 3D PrinterWorks.

“Ben’s company represents the seventh [3-D printing] company that we have here,” says YBI CEO Jim Cossler.

Just as they did with software companies, the incubator staff is building what Cossler calls a “managed cluster” of 3-D printing companies.

“We see them cooperating and talking and innovating together,” he says.

The YBI is renovating the former Vindicator building downtown, where it plans to house many of its additive manufacturing startups.

Cossler says one of the signs 3D PrinterWorks is on the right track is the product it’s selling.

“Nothing confirms a market like somebody saying, ‘Please take my money from me,’ ” says Cossler laughing.

Back in his office in the main building of the incubator, Kilar is busy working out the kinks on his newest version. Two of the new features are a larger touch screen – 5 inches – and an easier-to-use interface.

Mike Pollatta, a computer science major at Youngstown State University, is designing it.

“Considering we want to target the industrial commercial market, I want to make something without a lot of frills, but still pretty, is what I’m aiming at,” Pollatta says.

Because the CreatorBot is easy to set up and requires little care, Kilar sees his product used mainly by businesses.

“I can see selling to engineering firms or schools with art programs,” he adds.

A prosthetics company in British Columbia, Canada, is looking at the CreatorBot to help streamline its manufacturing operations.

“With it being so large, there’s really no limit,” Kilar says.

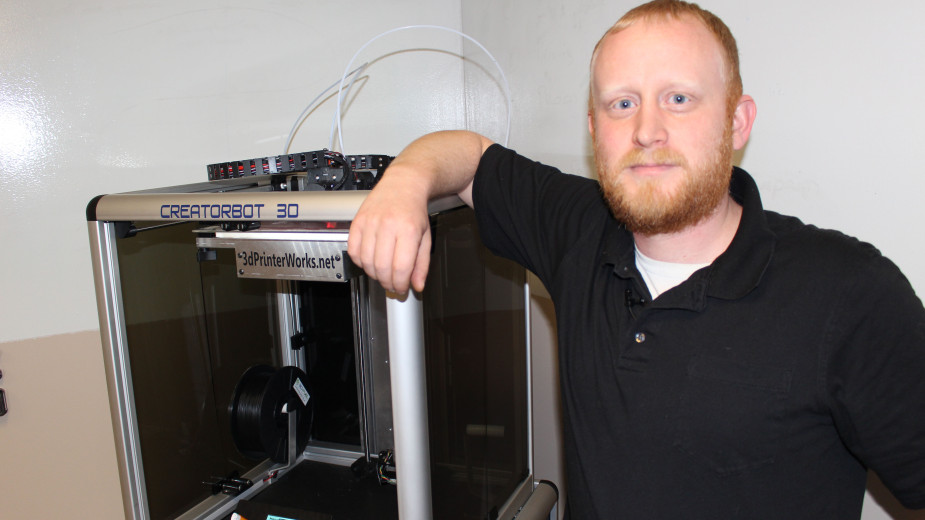

Pictured: Ben Kilar’s startup company, 3D PrinterWorks, sells the CreatorBot 3D printer.

Copyright 2024 The Business Journal, Youngstown, Ohio.