WARREN, Ohio – The general foreman at the Warren operation of Wheatland Tube, Matt Faraglia, scrutinizes a video screen and carefully monitors real-time images of steel pipe moving to and from the plant’s newly constructed warehouse.

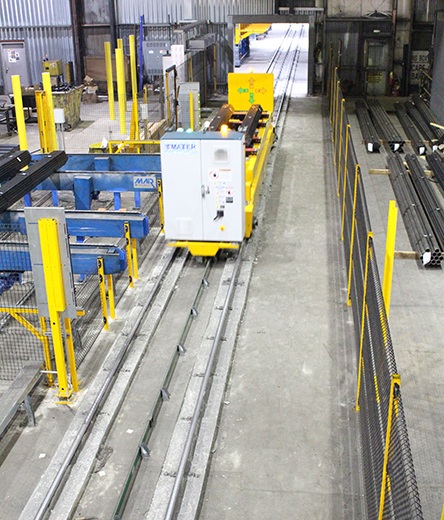

Automated shuttles transport bundles of pipe fresh from the mill onto elevators awaiting their arrival. Also alerted is a stacker crane that moves into position. It detects the specific product and carries the bundle to a pre-determined spot among steel shelving stacked 52 feet high.

Pipe moving outbound is picked from these racks in the same fashion and then shuttled to the shipping area of the plant. There a carrier is ready to transport the product to customers all over the country.

This is no ordinary industrial warehouse. All of the operation’s mechanics, movements, timing and internal logistics are choreographed to precision using a fully automated platform that points to the future of manufacturing in the Mahoning Valley.

“The objective has always been to have under one roof automated storage and retrieval,” says Ned Feeney, general manager of operations at Wheatland Tube.

Just more than two years ago, the company, a division of Zekelman Industries, decided to invest $50 million to construct an enclosed automated storage operation at its Warren plant on Dietz Road.

“For years, we’ve stored and shipped our product from the outside,” Feeney says. Traditionally, the shipping yard of the plant was filled with bundled pipe that had to withstand cold northeastern Ohio winters. “Northeast Ohio weather is not ideal – we’ve worked to get it indoor, to keep it dirt free, rust free,” he says.

However, the plant wasn’t large enough to accommodate the space needed for an indoor storage and handling operation, Feeney says. The answer was an 85,000-square-foot addition, 65-feet high, that would house an ultra-modern storage area designed to enhance safety, improve efficiency, and reduce the risk of imperfections to pipe that would otherwise be exposed to the elements.

Seeking a Solution

During the pandemic, leadership from Wheatland and Zekelman Industries – including CEO Barry Zekelman – traveled to Italy to examine a new system by Matter, a company that custom designs and manufactures automated storage systems.

“It was being used in different applications – one was brass bar, another was galvanized mechanical tubing,” Feeney recalls. “We really thought it was the best solution.”

Feeney says that Wheatland is among the first companies to use the warehouse platform for pipe products and “most definitely the first to use it for sprinkler pipe.”

Wheatland first commissioned the system at its plant in Rochelle, Ill., in an existing building. The Warren operation, which came fully online in October 2023, is the second Matter system to be commissioned throughout the Zekelman companies. A third site is nearing completion at Zekelman-owned Sharon Tube in Farrell, Pa., and a fourth automated warehouse at Wheatland Tube’s operation in Wheatland, Pa., is under development, he says.

“It’s the company’s objective to have an automated storage and retrieval system in all of its tube mills,” Feeney says.

Software and technology govern the entire storage and retrieval process, he explains.

“The tube comes off the mill and automated shuttles are in communication via our shop floor system,” he says. Information is transmitted to the shuttle that identifies the size of the pipe and shipment order. Then the shuttle retrieves the bundle and scans a corresponding bar code to ensure it’s the correct product. The shuttle then automatically moves into the warehouse, where an automated crane stores it in the appropriate stacking unit. “Everything talks to the shop floor system [with little human interaction],” Feeney says.

In some cases, it might be necessary to assume manual control in case of a problem, says Faraglia, the general foreman monitoring the process via cameras.

“If anything is flagged, I see it right away,” he says. “Indicators can tell me whether the pipe bundle is not positioned well. I could take over manually if necessary.”

The storage system is able to move pipe internally from one place to another within the racking platforms should inventory need to be rebalanced, Feeney says. “It can operate 24/7.”

Improving Competitiveness

Feeney says Matter’s advanced system gives Wheatland a competitive edge since it helps to reduce inefficiencies and prevent loss from damaged products.

“This will set Wheatland apart from the others,” he says. “This puts us far ahead of our competitors. It may take time for these things to show. But we’ll have a cleaner product and a more safely and efficiently handled product. That makes us competitive.”

Competition remains very stiff, particularly from imported pipe, says Kevin Kelly, president of Wheatland’s pipe division.

“It’s still significant,” he says. “Between 40% and 45% of [America’s] pipe is still imported.”

Tougher trade laws have helped to reduce imports from a decade ago but countries have also become adept at circumventing rules such as the 232 tariffs, which imposed duties of up to 25% on imported steel.

“There are lots of trade rules,” Kelly says. “But there’s lots of cheating.”

Violators, for example, might simply change the name of the product and ship it as a pipe or tube not covered under the tariffs, Kelly says.

“Other countries subsidize the product around the 232 tariffs,” he says, so the 25% duty has little or no effect on prices in the United States. Others ship semifinished products to countries that aren’t penalized under Section 232, where they are modestly processed, and then shipped to the United States.

“It’s like playing a game of Whac-A-Mole,” Kelly says. “These countries know how to get around things. It’s always a challenge.”

Wheatland’s Warren plant manufactures pipe that ranges from one inch in diameter to six inches. The new automated warehouse has space to handle approximately 14,000 tons; at present, just over 6,000 tons is inventoried.

The company buys all of its steel from domestic mills, Kelly says. “We have an owner that loves the business, is very hands-on, and very pro ‘Made in the USA,’” he says.

Improved Skill Sets, More Opportunities

Wheatland Tube’s autonomous warehouse stands as a testament to a company that is looking toward the future, which is heartening to the 145 employees there, says Jose Arroyo, staff representative for District 1, Sub District 1 of the United Steel Workers union.

“Anytime you’re getting a $50 million capital project, it makes us very happy about the status where we are here,” he says. “This project goes a long way to protect our workers here.”

Arroyo says the commitment also helps convey to potential future employees and USW members that today’s manufacturing is far different than a decade ago. “Because of the labor shortage, we’re getting a lot of new people entering manufacturing that have never been in manufacturing before,” he says. Wheatland’s automated system stands as an effective recruiting tool.

“You can make a good living – our members here make a great living,” he says. “This operation handles the pipe less, limits the amount of injuries. It’s one reason why the union and the company have worked toward this.”

Moreover, the employees have navigated the system’s learning curve with limited difficulties, says the plant manager, Donald Fowler: “It was challenging for sure but everyone did a really good and adapted to the technology pretty flawlessly.”

Fowler emphasizes that this new technology enables employees to vastly improve their experience and knowledge.

“The biggest benefit are the skill sets people are learning,” he says. “From supervisors to hourly folks, the fact that we’re dealing with automation right now is a builder.”

Rachel Cyphert, director of human resources at Zekelman Industries, says such new systems help to reduce the costs of upkeep for obsolescent machines such as side-loaders. “The equipment we’re now using is for the most part indoors,” increasing its longevity.

It’s also opened opportunities to recruit younger employees because of an updated, more inviting workplace, Cyphert says. “You don’t have to ship in the middle of December outside. Overall, the working area is much more desirable.”

Drivers benefit because of quicker turnaround times and unloading and loading at inside docks rather than outdoors, Cyphert adds.

The plant manager adds that Wheatland’s Warren plant symbolizes the advances that technology brings to modern manufacturing, which is more appealing than ever to younger workers. “Younger people will see this and understand this isn’t the old factory floor anymore,” Fowler says. “Part of this is recruiting. It’s cool.”

Pictured at top: Plant manager Donald Fowler says the storage and retrieval system has raised employees’ skill levels.