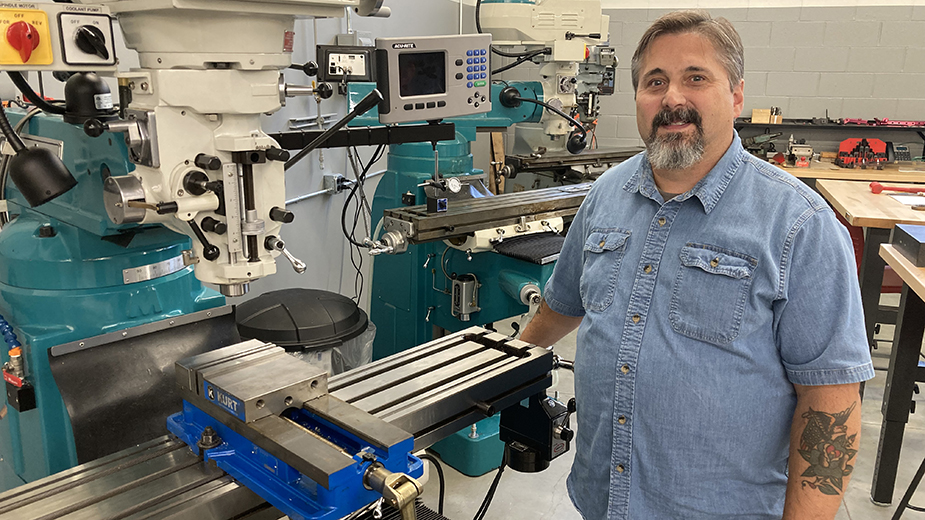

YOUNGSTOWN, Ohio – At 22, Joseph Thomas believes he has finally found his passion and path for life in the Machining Technologies program through the Youngstown campus of Eastern Gateway Community College.

Thomas, of Girard, had already tried Youngstown State University after graduating from high school and for whatever reason was one of the 1.5 million Ohioans who did not complete their degrees.

Next he tried the labor market, hoping he could work his way up in a company, but eventually just became frustrated.

He went to Eastern Gateway to seek an answer and says he found it when he was introduced to the Machining Technologies program. The program is also offered in the Youngstown State University Excellence Training Center on the edge of the YSU campus. It took him only a day to find the program, determine it was something he wanted, register and find the scholarships and financial aid to cover the costs.

“This was more [about] making an opportunity for myself in my life,” Thomas says. “Coming here and creating that new opportunity for myself has been a big plus.”

In his second semester of the program, Thomas has already been able to earn National Institute for Metalworking Skills (NIMS) credentials using the training and knowledge he has gained through the introductory class. The certificated hours he spends taking the classes and working on the machines in the lab can lead to a position in entry-level machining in shops throughout the Mahoning Valley.

“Here at Eastern Gateway, I have learned how to operate a manual lathe and mill and I’m learning how to operate a CNC lathe and mill,” Thomas says. “There’s a lot more industry around the area and I’ve taken a lot of liking and passion toward machining since getting into it. It’s been a great experience so far.”

When he finishes his training, Thomas will have plenty of opportunities to pursue. A Sept. 22 search of the OhioMeansJobs website for machinist jobs within 30 miles of the Youngstown area turned up 46 openings.

Thomas would like to secure a position where he can find fulfillment, build a career, work his way up in the machining trades and obtain more education down the road.

He’s looking at a few options now. Living near his family appeals to him and Vallourec Star is near his home. “I’m a person. You grow where you are planted. So I would rather go with the local option,” Thomas says.

INTRODUCTION TO MACHINING

The introductory class combines both bookwork and hands-on training, says John Burr. Burr is the Introduction to Machining instructor for the program, a class he teaches in a “wonderful facility,” as he describes the Excellence in Training Center lab that combined the resources and equipment that both YSU and Eastern Gateway own.

Although the course is not credentialed, students gain the skills, training and certifications that can lead to an entry-level machining position or more training if they choose. Burr shows students how to operate all the machines in the lab and their capabilities.

“After 235 hours, they have a pretty good idea if this is something they want to pursue as a career and, of course, we help them try to find an introduction-level career job,” he says.

Burr’s introductory course can lead to two or three NIMS credentials, which are obtained after being tested on the materials and use of the machines.

“There’s quite a few of them,” Burr says of the NIMS credentials, “and if you get through them all, you might be on par with a journeyman.”

Although the class attracts some younger students like Thomas who have decided college is not working for them, Burr says he also gets many older adults who have decided it’s time for a change.

“Anyone who enjoys working with their hands and likes to build things may excel working in a machining job,” Burr says, noting there are at least 50 avenues of jobs available just by taking the introductory course. These include jobs outside the machine shop such as sales and estimating.

COMPUTER NUMERIC CONTROL (CNC) COURSE

After completing the Introduction to Machining course, the next step for many is the CNC course. Paul Coombs, the noncredit CNC instructor, says it’s basically an introductory class to CNC milling and lathing, which includes 90 hours on the mill and 90 more on the lathe.

His class is available evenings, which makes it possible for those who have a job to more easily fit the program into their schedules.

“This is more streamlined, more like a technical school,” Coombs says, noting it does not require all the general education classes required for a college degree and the math involved is what is needed to program and operate the equipment.

Coombs comes from a mold shop, giving him familiarity with the capabilities of the machines in the lab. One he describes as having full three-dimensional machining capabilities with a fourth-axis, which allows for some rotary work to be accomplished as well.

Students attend the classes about 10 hours a week over a semester. In the CNC class it is possible to earn four NIMS credentials.

“It’s streamlined for sure. But it gets the job done,” Coombs says. “People are definitely prepared to go out into the workforce after this class and get an entry-level CNC machining job, whether it be an operator, a programmer. It’s up to them and what they learn.”

The machines are very efficient, Coombs says, and most machine shops operate CNCs, making those skills very in-demand, not just in this area, but across the country.

Usually, obtaining CNC skills leads to a pay increase for those working in the trade. New CNC machinists can make $18 to $20 per hour to start. With more experience or training, Coombs says, someone in the field can make $35 to $40 per hour.

WORKFORCE DEVELOPMENT

Not only is the Excellence in Training Center used by individuals who want to explore a new career or learn new skills, but Alex Hertzer, assistant director of the Mahoning Valley Manufacturers Coalition, says his organization’s manufacturing partners also use the lab for workforce development.

MVMC matches training programs at Eastern Gateway with manufacturers when they need their employees to develop new skills and learn the latest equipment.

“It’s vital,” Hertzer says. “To be able to have a full machining and welding program right here in Youngstown is amazing. This facility is invaluable to the community – to be able to offer these services to new employees and incumbent employees too.”

With about 60 member manufacturers in the coalition, Hertzer says its members not only use the machining programs at Eastern Gateway, there also is interest in the community college’s industrial maintenance and welding training.

“One of the other ways we work with Eastern Gateway is with our WorkAdvance program,” Hertzer says. “WorkAdvance is a program that aims to help those with little to no manufacturing experience gain gainful employment in manufacturing in entry level positions. Eastern Gateway is positioned perfectly to be able to help us with the technical training for that program.”

The manufacturers coalition also collaborates with Eastern Gateway for programs such as Tooling Youth, where students can become a Certified Manufacturing Associate, along with career readiness with another community partner. Hertzer says the program helps to connect them directly with an employer and go through interviews.

“We definitely would not be able to do this without Eastern Gateway,” Hertzer says. “Right now is a great time to get into the manufacturing world.”

Sometimes companies help to pay for the program for their employees and some tuition is paid through TechCred, a state program that provides money to teach technology skills for employers and future employees.

MVMC members, Hertzer says, have several occupations emerging as in-demand jobs, including machining, welding and industrial maintenance. In addition, with the increase in technology, he sees future job growth in electrical maintenance and robotics on the horizon.

EGCC FUTURE PROGRAM PLANS

By partnering with YSU and creating the Excellence Training Center, Arthur Daly, senior vice president and chief development officer at Eastern Gateway, says the college has been able to expand its career accelerator programs and help students like Thomas find opportunities to build long-term careers.

The manufacturers coalition and other industry partners are looking for shorter ways for future employees to obtain the needed skills and credentials they require. Daly says the goal is to have the lab working 24/7, providing training days, evenings and weekends.

“A lot of companies are looking for people to have those industry skills. They want to make sure they have those skills and flourish,” Daly says.

Machining is one of the bigger programs that can be found on the Eastern Gateway Career Accelerator website, EGCC.edu. But the school’s offerings also include welding, industrial maintenance, artificial intelligence and the IT industry.

Daly says the community college will be launching training programs for the electric vehicle industry.

“We’re a Mitsubishi educational partner and we have been training engineers and maintenance employees at Ultium Cells. We’re also going to build a state-of-the-art electronics lab and an EV charging lab, as well as an EV technicians lab to meet the growing demands of electric vehicles in the 21st century.”

Being part of the Mahoning Valley in the future makes sense to Thomas and that he can train here has made a difference for him.

“It’s really the best option,” he says.

Pictured at top: Eastern Gateway student Joseph Thomas works on a manual lathe.