YOUNGSTOWN – On the shop floor of Gasser Chair is a piece of equipment that’s been with the company since its early years.

Mark and Louie Gasser – company president and project & tooling engineer, respectively – prepare the equipment that was hand-built by their father and two uncles using scrap components. With patience, well-timed motions and a lot of oil, the pneumatic device springs to life, quickly bending a piece of aluminum tubing.

Removing the tubing from the 70-year-old bender is another matter. The brothers wrestle with several switches and levers trying to dislodge the frame, sharing a good laugh when a disconnected air hose blows Louie’s hat off his head.

Fortunately, the bender is just for show. It’s a reminder of where the company has been and how far it has come.

In the mid-1940s, brothers George, Louis and Roger Gasser set up shop in a small barn house on the property where the company’s headquarters stands today – 4136 Logan Way in Youngstown. After World War II, aluminum became a very common metal fabricated by Youngstown companies. The Gasser brothers took an interest in that, says Mark Gasser.

The brothers fabricated aluminum door fronts, parts for a small prototype helicopter and repaired aluminum beer kegs, he says. They got an idea to build lightweight aluminum frame furniture for the hospitality industry.

George Gasser – father to Mark, Louie and Gary Gasser, the company’s CEO – took some samples to the National Restaurant Association trade show in Chicago. He came home with a few orders, “and it just kept growing from there,” Mark Gasser says.

“They found a real need for built-to-order furniture,” Gasser says. “Not just lightweight, but also in a customer’s preferred style and colors.”

Built-to-order furniture kept the company growing for the past 75 years. The vertically integrated company does the designing, engineering, manufacturing, marketing and sales of its products, Gary Gasser says.

“That gives us the opportunity to control the quality, as well as the supply to some degree,” he says.

Gasser got its start in the hospitality industry serving restaurants, private clubs and hotels, he says. In the late 1950s and early 1960s, the company broke into the casino industry as it started to grow.

“They originally only had chairs at poker tables, blackjack tables,” Gary Gasser says. “Slot machines didn’t have stools. And our father was one of the people who talked them into putting stools at slot machines, creating the customer interest to stay and play longer.”

Growth leveled out until the mid- to late 1970s when George Gasser developed and patented an extruded plastic protective edge that runs around the chair’s perimeter. That was the impetus for 20 to 30 years of added growth, Gary Gasser says. Today, hospitality and casinos comprise a bulk of Gasser’s business, almost a 50/50 split.

To meet the needs of increased business, Gasser expanded its manufacturing space. The original factory on Logan Way became its headquarters and, in the early 1970s, the company moved its primary manufacturing shop to a 100,000-square-foot space just down the road. It expanded further into a 75,000-square-foot building on-site.

The main shop handles every step of the manufacturing process, including metal and wood shops, finishing, upholstery and packaging. With the exception of a few components, each chair produced by Gasser is manufactured in-house, says Jesse Potter, brand development manager. In fact, about 75% of the aluminum Gasser uses comes from local extruders, he says.

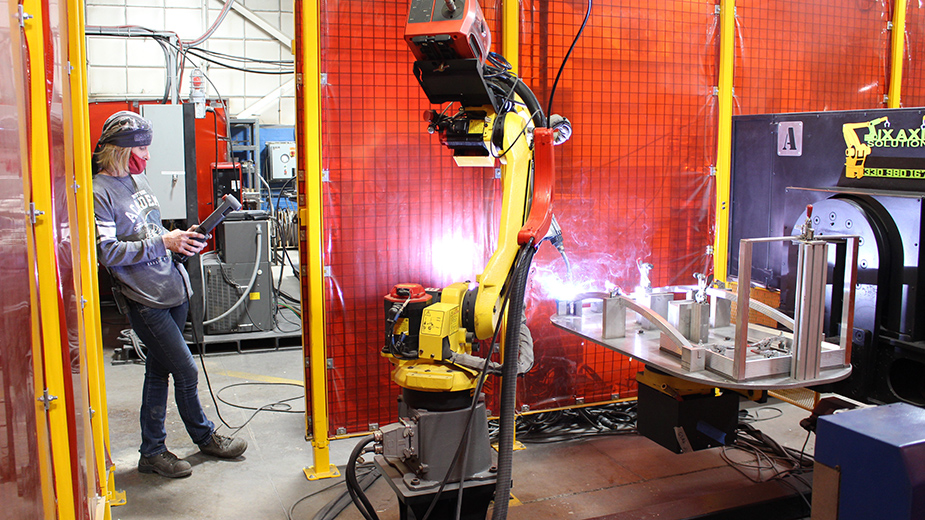

Investments in recent years have made the manufacturing process more efficient. In 2019, the company invested $170,000 in a robotic welder, which ensures a more efficient and consistent weld process compared to hand-welding, Potter says.

Four years ago, the company purchased a $200,000 bender to shape its aluminum frames, says Jack Oakes, metal shop manager. Unlike the original, hand-built bender that the founders used for decades, the modern equipment makes all the needed bends in one sitting.

The metal shop runs about 35 to 40 pieces of equipment regularly, he says. “Then some of it is special equipment that we use once in a while for particular customers who want custom chairs,” Oakes says.

Over the years, Gasser opened two additional operations in Hubbard, which it used primarily for warehousing as it grew, Gary Gasser says. That allowed the company to buy back furniture from customers who are buying new.

“So a customer doesn’t have to worry about getting rid of the furniture they got,” he says. “With a casino, that’s quite a bit.”

Gasser repurposes the old furniture, some of which doesn’t need much more than a cleaning or reupholstering, and is resold as “experienced furniture,” he says. Furniture that can’t be used is broken down and the components are recycled

“We offer a 10-year warranty on our products. So it’s not a problem to expect that the life is that much or more,” he says.

As with many companies, 2020 wasn’t kind to Gasser. The company took “a good hit” during the Great Recession, but not as bad as 2020, Gary Gasser says. “Business was really cut in half, if not more,” he says.

Because of the COVID-19 pandemic, mass gatherings were curtailed or completely stopped, impacting the industries that thrive on such gatherings.

“And those were our customers,” Mark Gasser says. “They’ve been hurting. And we’ve been sharing the pain with them.”

Gasser entered 2020 “with a very full order book,” he says. Though none of the orders were canceled, almost 90% were delayed. A year later, some customers still can’t accept delivery, he says.

Initially, the company wasn’t deemed essential. So it shut down for six weeks and had to lay off workers, he says. After reopening, it brought back about half of the 150 it employed.

Still, national and international sales teams are optimistic. The company has shipped orders to Europe, as well as throughout the United States, including Texas and California.

“We are slowly working through that list of postponed orders, as well as booking new business,” Mark Gasser says.

As customers use more outdoor spaces, Gasser is developing several prototypes of outdoor furnishings, he says. With the exception of different tooling and adding a few UV-resistant finishes to its products, the company hasn’t had to change much to accommodate the outdoor furnishings. Moving forward, Gasser expects the company will evolve into that realm of furnishings.

Gasser also expects virtual presentations to become more prominent in the industry, he adds. Before the pandemic, the company primarily generated business by attending 18 to 20 trade shows around the world each year, he says.

When those were halted, Gasser converted an upholstery library at its headquarters into a showroom to conduct virtual presentations for customers, training sessions for sales staff and to participate in virtual trade shows.

“Everyone is anxious to get back out and meet people and have face-to-face conversations,” Mark Gasser says. “But I think that the virtual side of things is going to stick around. And we’ll use that to our advantage. It’s certainly more cost-effective if you can make it work.”

And while the Gassers know in-person meetings will eventually come back, they are already thinking about how to meet the increased demand that is sure to come when everything opens completely once again.

“In fact, that’s one of my biggest concerns,” Mark Gasser says. “How are we going to ramp up? And how quickly can we do it? As well as the supply chain side of things.”

Many industries are still struggling to catch up from the shutdowns, he says. It’s been a struggle getting raw materials such as wood, metal and plastic into the shop, which has sometimes delayed orders for weeks.

“Lead times are way out. Prices are up. So it’s going to be a challenge,” he says.

One way to accommodate the ramp up is cross-training employees. Because the company has fewer people than it used to, it needs those workers to handle more operations, he says.

Some individuals in cutting and sewing are also working in wood fabrication and “moving basically with the order as it rolls through production,” he says.

“I expect we’ll continue to do that, and perhaps be more robust in cross-training employees,” Gasser says.

As for the next 75 years, the Gassers say they are proud to continue operating in the Youngstown area with the third generation of the family working in the company; Gary’s son, Mat, currently works in upholstery.

“It’s really hard to beat the work ethic of this area, and the ‘can-do’ attitude that is crucial to our industry,” Mark Gasser says. “We’re trying to lay the groundwork to make certain when Gary and I pass the torch, that it will continue. We have a strong reputation in the industries that we serve. And we think that it will lay the foundation for the future.”

Pictured: Mark and Gary Gasser show off the company’s new outdoor products.