YOUNGSTOWN – Members of Ironworkers Local 207, Youngstown, have over the past eight months witnessed the temperatures drop and steel rise on a 2.8-million-square-foot ultra-modern factory.

“We went from the nice warm weather to one degree out here,” said John Crisopoulos, steward with Local 207. “We just kept plugging away at it.”

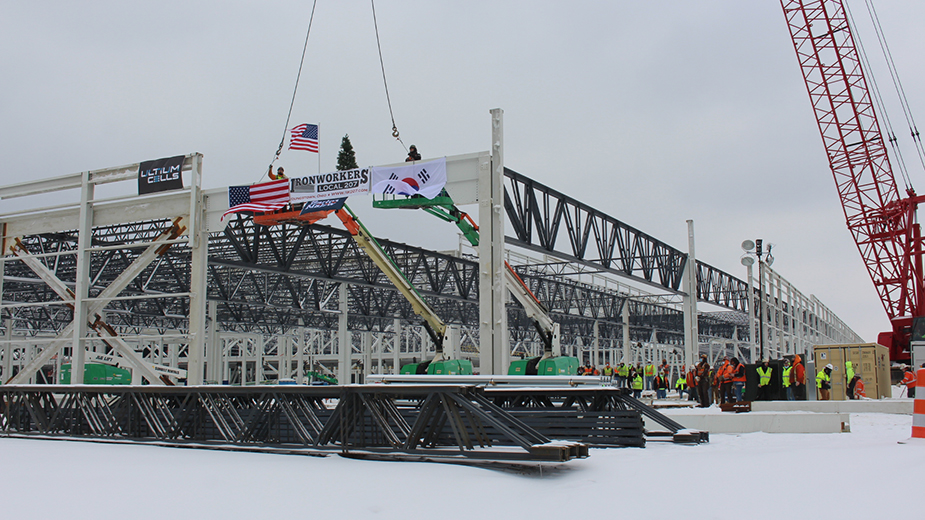

Crisopoulos was among the 80 or so members of the Ironworkers on hand in frigid temperatures Feb. 19 as the final beam of structural steel was put in place at Ultium Cells LLC’s $2.3 billion electric-vehicle battery manufacturing plant in Lordstown.

“To me, it’s an accomplishment for the guys,” said Rob Gadson, superintendent for the Ironworkers.

The event, commonly known as a “topping out” ceremony, is a tradition among Ironworkers. The vertical final beam was signed by tradesmen, company officials, employees, construction managers and others, and then topped with a small evergreen tree before it was hoisted into place near the northeastern corner of the structure.

About 650 workers are on-site building the massive plant along Tod Avenue, which is scheduled for completion by mid-2022, said Tom Gallagher, Ultium’s plant director.

“We will see as many as 1,000 people constructing this building” as work begins inside during the installation phase, he said. “We’ve made tremendous progress.”

Thus far, more than 500,000 construction hours have been logged at the site. “We’re right on schedule, which is a tremendous feat given the COVID conditions,” Gallagher said.

Ultium, a joint venture between General Motors and Korea-based LG Chem, will manufacture battery cells for GM’s electric vehicle portfolio.

Ultium intends to bring on board 30 full-time employees by March 1 and gradually expand the workforce to more than 1,100 when the plant begins production, Gallagher said. The new positions range from engineering, maintenance, quality and production. “They’re part of our launch team,” he said, noting Ultium had hired about 10 employees as of Feb. 19.

Throughout this year, process equipment will be installed as construction continues on other parts of the building, Gallagher said. The company plans to have construction substantially completed by the end of 2021, begin installing equipment this summer, and continue to add process machinery into 2022.

“We have a mixing, coating process in our electrode area,” he said. “That will be among the first equipment installed.”

Then, equipment related to cell assembly and formation would be added to the plant. “This is not a single process or flow,” Gallagher said. “It’s a multi-line environment – so really high capacity.”

Gallagher said the new plant includes improvements in process flow and battery cell design.

“The nature of manufacturing drives continuous improvement,” he said, “and we’ve found ways to improve the process.”

Among the improvements is the size of the building, compressing work activity to the first floor to improve the flow of people and material, and the addition of superior advanced manufacturing technologies. “A variety of things have been done that are really progressive,” he said.

The plant includes areas that can be modified or adapted as cell design changes, or for expansion if necessary. “We always need to look to the future,” Gallagher said. “But right now our focus is delivering the current chemistry which is critically important to GM’s electrification future.”

Earlier this year, GM announced its goal to achieve a zero-carbon footprint on all of its vehicles by 2035.

“There are a number of different options that this cell can serve and we’re really excited about it,” Gallagher said.

Early phase production of the Ultium battery cells should start by the beginning of next year, while full production would coincide with vehicle launches scheduled for mid-2022, Gallagher said. “It’s all about having an aggressive timeline and coming to market as quickly as we can with the highest-quality product.”

Michael Kim, project manager for LG Energy Solutions, the battery division of LG Chem, said the Lordstown plant is exceptional for a battery manufacturer since it is designed as a single large factory under one roof.

“This has the largest capacity for just one plant,” Kim said, noting annual capacity would be more than 30 gigawatt hours of battery power. To put this into perspective, a single gigawatt is enough to power 110 million LED lights.

“Typically, we design separate buildings,” Kim said.

However, through the partnership with GM and adopting a new design-build strategy, Ultium was able to fashion a plant that could accommodate all manufacturing processes in a single building that measures more than 30 football fields.

Kim credits the team approach between GM, LG Chem, the trades, and the project’s general contractor, Michigan-based Barton Malow, as a major factor in keeping construction on track.

John Hanmer, project director for Barton Malow, said to reach this point in less than 10 months during the throes of the Covid-19 pandemic is a testament to the efforts of hundreds of workers and managers. “It’s taken a lot of blood, sweat and tears to get to this,” he said. “This is just the beginning though. We’ve got a long way to go.”

Hanmer said about 10% of the concrete slabs are poured, preparing the southern end of the building for equipment installation. “We have about half the building sided. About one-third of the roof is on.”

In mid-November, Ultium acquired 144 acres just south and west of where it’s constructing the new plant. The acquisition nearly doubles the size of Ultium’s land holdings there to more than 300 acres.

In March 2020, GM purchased 158 acres along Route 45 from NorthPoint Development for $5.1 million to make way for the Ultium project.In November, Ultium acquired a 45.6-acre parcel at the corner of Route 45 and Hallock-Young Road and another 98.6-acre contiguous parcel that extends west across a parking lot and then north along an old railroad spur for about 1,600 feet.

Pictured at top: Tom Gallagher, plant director, says full production is scheduled for mid-2022.