KENT, Ohio – A company born out of pioneering technology and developed at Kent State University during the 1980s has found widespread commercial success in a variety of markets.

Kent Displays Inc., established in 1993, manufactures liquid crystal display, or LCD, products at its headquarters in Kent. Since then, the company has cracked the toy, education and stationery markets. As it looks ahead, it has even bigger plans for its technology.

“We continuously reinvent ourselves,” says Don Davis, technical services business development at Kent Displays. “We continue to innovate.”

Kent Displays uses LCD technology in its signature product, the Boogie Board – an electronic writing tablet that has captured the global retail market for consumer electronics, gaming and toys, he says.

Critical to the success of the company is its development of flexible LCD film manufactured at the company’s plant in Kent, says Joel Domino, president and chief financial officer. “Initially, all of our displays were under glass.”

LCD technology was invented at Kent State during the 1970s, Domino says. In 1970, James Fergason, while working with Kent State’s Liquid Crystal Institute, introduced the first operational LCD. Today, these screens and displays are found in computers, televisions, calculators, watches and medical devices. They are used in hundreds of other applications as well.

Kent Displays, co-founded by William Manning and William Doane, then director of the Liquid Crystal Institute at Kent State, was among the first to commercialize LCD technology. The first screens, Domino says, were encased under glass and used for customers such as transportation companies so that they could display their routes and destinations.

“We were looking for a place for it in the market,” Domino says. “We found some really good niches but never found a really big application for it.” Additional delays were incurred as a result of a six-year court battle with a Chinese company over intellectual property and patent rights.

“We ended up winning the case. But by that time their company went out of business and they went back to China. It put us behind substantially,” Domino says.

“Then, we realized that we could be the first to use flexible substrates – meaning you could manufacture the LCD roll-to-roll rather than a batch of glass at a time,” Domino says.

The company spent approximately eight years of intensive research and development to reach a point where it was confident the concept could work. It also engaged in R&D for other customers, including the U.S. military.

“In 2008, we made the decision to build the first roll-to-roll LCD production line in the world,” Domino says.

At the time, Kent Displays had several ideas in mind for this new product, he continues. “We were making flexible displays for Timex wristwatches and trying to do some development that would fit these displays in credit cards,” he says. “We also did displays on vinyl fabric. We were the first in the world to do that.”

Another idea was to use these flexible LCD screens for a whole new product – an LCD electronic writing tablet that can erase at the touch of a button and then be reused.

“When we developed the prototype, we thought it was great,” he says, recalling how his children, during a trip to visit relatives, were captivated by it. “We started to market it to toy companies.”

Toy retailers, however, wanted to sell the tablets at $10, Domino says, a price far too low to realize a profit. Instead, the company began to sell the tablets directly on Amazon and in kiosks at nearby malls.

In 2010, a writer for Popular Science magazine wrote a profile of the company and product that demonstrated both its technical and practical uses. “The day that article came out, everything on Amazon sold out,” Domino says. At the time, the writing tablets sold for $34.99.

A second break occurred when the retailer Brookstone took notice of the product and wanted to place it on its shelves. “We told them we could probably sell them 100,000. We ended up selling them 200,000,” he says.

Domino says the market for its product exploded over the following years. “We developed this market and we went from nothing to two million units a year within five years,” he says.

Today, because of its patent rights in the United States, Kent Displays enjoys an approximately 90% share of the domestic market of this product, and 100% market share in retail stores, according to Domino.

“We can keep the Chinese out of retail because of our patents,” he says.

Barnes & Noble, for example, is among the larger retailers to carry the Boogie Board.

Online market share through Amazon is a different matter. “We have about 30% [share],” he says, because the site is flooded with replicas from China.

Still, the Boogie Board concept has evolved into several products and markets, Domino says. Some of the latest versions include smart technology that allows users to import written notes to their computers or mobile devices, which he says is perfect for students.

Based on the battery life of the tablet, a Boogie Board is the equivalent of 50,000 sheets of paper, Domino says.

The product has also grown from a small, handheld tablet to larger screens up to 50 inches in width used in classrooms, corporate meetings, brainstorming sessions and applications in the medical field, he says.

All of the LCD film is produced in Kent, says the company business development specialist, Davis. The hardware, such as the plastic frame and other accessories, are manufactured, either in Asia or Mexico.

At present, the company operates three manufacturing lines – all in Kent – each one producing LCD film for products of different sizes.

The “Gen 1” line today produces its Versa-Notes product, the “Gen 2” line manufactures high-volume screens for traditional size Boogie Boards, while the “Gen 3” line produces the large, wider-screen displays, Davis says.

Kent Displays employs 85.

The company recently initiated a new shift schedule where employees work 12-hour shifts four days one week, then three 12-hour days the following week, Davis says.

“That way they get to 80 hours over two weeks,” he says.

Before a new product moves into full production, it moves through an ideation and prototype phase. Essentially, the LCD film is composed of two pieces of thin, flexible plastic with a liquid crystal mixture sandwiched in between, Davis says.

The liquid crystal component is just five microns thick. “Just to put that into context, a human hair is about 50 microns thick,” Davis says.

The latest product at the company is VersaNotes: small, tile-size, square pieces of LCD vinyl fabric used to write personal memos or reminders. That product, except the custom pen, also is manufactured in Kent, he says. The pen, which holds the electronics and battery, is produced in China, Davis says.

VersaNotes acts the same way as a Boogie Board. Once a user writes or draws on its surface, that engages the liquid crystals to display the words or image. A small conductive piece inserted at the corner connects with the back of the pen so the user can erase the note with a single tap.

Versa-Notes are produced in three colors, three in a package that includes the pen. Once the user has a pen, then he can purchase larger packages of Versa Notes. “These sell for just a couple of bucks,” Davis says. “But we’re able to make them all here.”

Kent Displays has also discovered another market outlet, says the sales manager for the company promotional products division, Ryan Merlene. “We’ve found a way to customize the Boogie Boards for specialty advertising,” he says.

Merlene has found success by etching and printing logos of various retailers onto the product frames – especially independently owned gaming stores and card shops.

“We’ve reached out to them across the country,” he says, since players like to use the tablets to keep score. “They’re selling them in their stores with their logos on them. So, it’s good brand awareness.”

All of the testing and production is done in clean rooms to prevent any defect from damaging the screens, Davis says.

“We have this opportunity to use our machines and technology for other areas that need high performing, high-tech solutions,” Davis says, such as those in the medical field.

“We’re able to process complicated materials very precisely in a very efficient manner,” he says. “We’ve discovered it was a unique capability that we had.”

Among the potential new markets for the company is the home improvement industry – using LCD technology for dimmable windows, for example – and the silicon chip industry, Domino, the CEO, says.

“We have a product that could help in the processing of semiconductor wafers and suppliers to chip makers,” he says.

“The key is innovation. We’re constantly looking for new things or we won’t survive. If we don’t spend on innovation and our mindshare on it, we’ll die.”

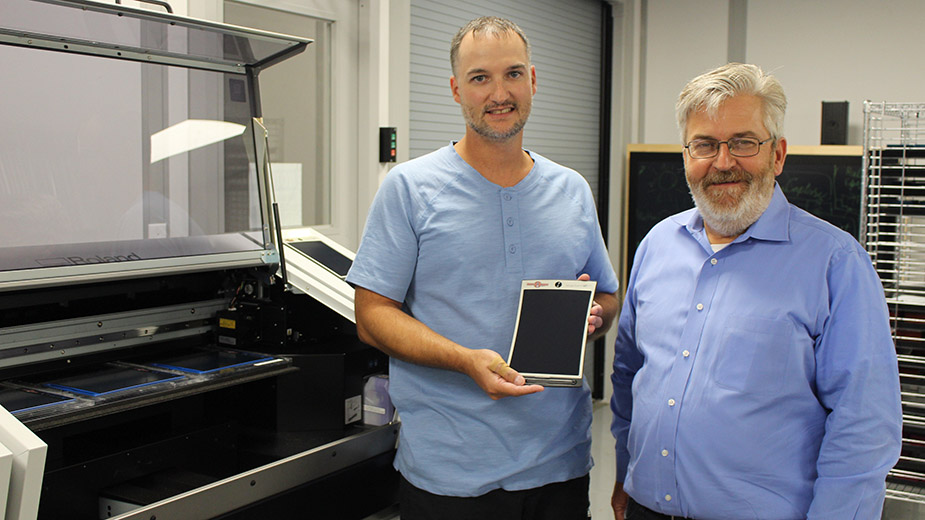

Pictured at top: Ryan Merlene is the sales manager for the company’s promotional products. Don Davis oversees technical services business development.