YOUNGSTOWN, Ohio — The adaptability of Ohio’s manufacturers is evident as companies retooled plants and shared collaborative engineering designs to supply frontline workers with desperately needed protective gear in the ongoing battle against the coronavirus.

Producing millions of medical personal protective products for hospitals, long-term care centers and Ohio’s stockpile in less than a month is an example that manufacturing today isn’t the same as it was decades ago.

“I’m super-proud of our manufacturers. This is one moment in time where manufacturers can be seen and appreciated,” says Ethan Karp, president and CEO of Manufacturing Advocacy & Growth Network, or Magnet. “Hopefully this can help fill the skills gap of people not wanting to go into manufacturing. People can see that manufacturing is no longer seen as a dark and dirty industry, but one of technology and innovation.”

Jessica Borza, director of Mahoning Valley Manufacturers Coalition, agrees that manufacturing will be seen differently once the pandemic ends and garner interest as a career choice.

“It’s phenomenal to me that manufacturers were able to produce a million items of need every week,” Borza says. “It’s not only patriotic, but provides a bigger service-type of message for young people to go into manufacturing and contribute to the world. The ability to be creative and innovative to help with the next world’s challenge is huge.”

Matt Joing, vice president of Butech and president of MVMC, believes that when manufacturers are able to communicate their high-tech abilities, recruitment is easier.

State and local manufacturers are actively recruiting young people to pursue manufacturing as a career because of a labor force shortage and skills gap as more of the workforce is at retirement age.

As cases of COVID-19, the disease spread by coronavirus, moved through Ohio and health-care workers faced shortages of protective equipment, Gov. Mike DeWine sought help from manufacturers on April 1. It didn’t take long for manufacturers to come forward.

Hospitals reached out to Magnet, which began working with engineers to design face shields. The network partnered with the Ohio Manufacturers’ Association, Ohio Hospital Association and JobsOhio to create the Ohio Manufacturer’s Alliance and turn out supplies to fight COVID-19.

“Soon after addressing the need for manufacturers at [DeWine’s] daily briefing, 2,000 companies stepped up,” Karp says. “Not all of the companies could retool to mass produce the supplies, but it was so inspiring how many manufacturers were willing to do so.”

DeWine highlighted manufacturers’ efforts during his daily briefing May 1, featuring a video of companies that retooled in less than a month to produce everything from hand sanitizer to filters for N95 respirator masks and developed technology to convert CPAP machines into ventilators.

“Ohio’s manufacturing alliance coordinated 19 manufacturers coming together, partnering with three hospital groups to make one million face shields. It’s the Ohio way,” DeWine boasted.

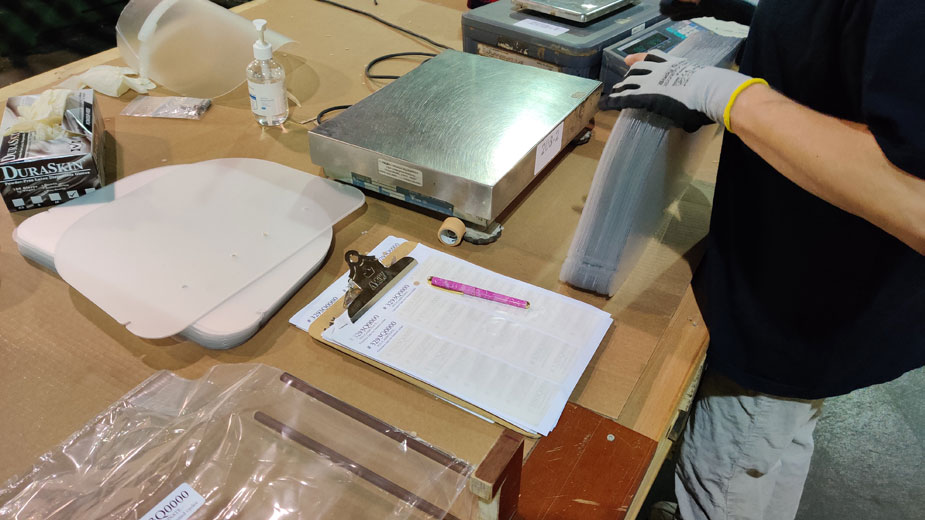

One of the 19 manufacturers is ITEN Industries, which has four plants in Ashtabula. Workers at the tool and die plant are die cutting the shield visor (the clear plastic part) at a rate of about 30,000 per day, according to Karp. There are six companies in the alliance partnering to make pieces and assemble shields that are being sent to Ohio’s stockpile.

Borza says no members of MVMC could scale up for mass production, but several area companies adjusted their operations to make non-surgical masks, face shields and hand sanitizer.

Candella Micro-Distillery in Boardman, which makes vodka, wine and other spirits, received procedures and formulas from the World Health Organization in mid-March and is producing hand sanitizer, the product that has eluded store shelves and supply chains from the pandemic’s onset.

Priority for distribution is given to hospital and health care workers, first responders and the elderly, according the company’s Facebook page.

The hand sanitizer can be purchased at the distillery, 4440 Market St. in Boardman. For information, call 330 518 5006.

Juggerbot 3D, a Youngstown Business Incubator portfolio company, designed and printed 250 face shields in the past month that were shipped to senior-living centers in Lorain, Youngstown, Warren, Cortland and Columbiana, says its vice president, Dan Fernback. The shields, printed in Juggerbot’s space in YBI, are not designed to stop the spread of the coronavirus, but can be used by hospital workers to protect against droplet transmission through the eyes, nose and mouth.

At the beginning of May, Fernbeck says he was contacted by an area dentist who asked for a redesigned shield specifically designed for dental work.

“It was brought to our attention that shields out there are not protective enough for dentist offices because of droplets coming into contact with the chin and ears,” Fernback says. “They needed more protection than what a nurse or caregiver would normally need. We modified the shield to go under the chin, cover the ears and barriers on forehead.”

The company has produced seven of the redesigned shields, but can produce 100 in a week if given lead-time to purchase components and balance the company’s production schedule.

GLI Pool Products in Youngstown used its automated machines usually used to cut vinyl linings for swimming pools to create 100,000 masks for medical workers.

The masks aren’t the high-grade N95 respirator masks used by medical workers to care for COVID-19 patients. Magnet’s Karp points out that raw material for these masks is in short supply.

Borza says MVMC member Gasser Chair brought back seamstresses who had been furloughed as a result of the state’s shutdown to help sew the masks being made by GLI Pool Products.

Other Ohio manufacturers who could produce non-surgical personal protective equipment formed an online exchange database known as Ohio manufacturers repurposing project.

Karp explains the project has a database listing for companies to post and sell personal protective equipment and other safety items first responders or business owners use.

“Manufacturers who are able to produce personal protective equipment but weren’t part of the alliance eventually were brought into the exchange,” Karp says. “We realized we had a marketing problem because the quantities of PPE had wider ranges for need other than just hospitals.”

Butech’s Joing says he used the exchange to purchase face coverings for employees, a required policy recently ordered by DeWine as part of Ohio’s strategic plan to reopen businesses.

Butech, which manufactures equipment for steel mills and steel coil processing, has been open as an essential business and following all safety orders given by state and federal health authorities, but masks worn by employees had been a recommendation only. The new order says employees must wear a face covering unless the employee meets certain exceptions, such as the environment is not reasonable, among others.

“Face coverings have been a challenging process in trying to figure it out and what works,” Joing says. “We had started making some of our own masks with shop towels and were able to find nose clips on the exchange. We also ordered some elastic clips for the back of the face cover.”

Joing says he is impressed at how quickly the supplies are delivered compared to ordering from Amazon, where some items are unable to be shipped until July.

“We were able to order some other masks from a company in Akron and one in Columbiana as well as a local sporting goods store. It’s nice to do business with local businesses,” he says. “I’m really impressed with the amount of PPE available on the exchange.”

Butech Bliss, like other companies, still finds it difficult to find supplies of hand sanitizer and disinfectant wipes. Some of the company’s suppliers normally used to buy tools and other equipment are beginning to make cleaning and disinfectant supplies, he notes.

“This was not conceived as innovation but an emergency measure to get this into the hands of private and market enterprises,” Karp says, although if a smaller company finds a niche in continuing to produce these products there most likely will be a market because companies might not want to rely on overseas companies for supplies after the shortages health systems have faced.

“The exchange is a way for manufacturers unable to mass produce to sell products,” Borza adds.

Karp explains the exchange is set up so buyers are directly connected to vendors. “It’s not a well-oiled machine because of the speed in which it was set up, but is an example of how manufacturers have stepped up for brokers who don’t want to wait on procuring foreign goods,” Karp says.

Pictured: ITEN Industries in Ashtabula answered the governor’s call and is cutting face shields.