CHAMPION, Ohio — Construction technology was Hunter Wess’ specialty at Trumbull Career and Technical Center — learning about innovative tools, machinery, modifications and software utilized during the construction phases of a project.

In March, his path, along with four others changed as they took their skill sets and prepared for a potential career with Extrudex Aluminum Inc. in North Jackson through WorkAdvance.

“I just thought this could be a really good opportunity,” says Wess, a high school senior who comes from Hubbard High School.

Jessica Borza and Sue Watson from the Mahoning Valley Manufacturing Coalition approached TCTC Trade, Industry and Agricultural supervisor Anina Karlovic about trying this initiative at the high school level — one of the first institutions to do so. Normally, this is an adult-based program paired with partners such as Eastern Gateway Community College.

Extrudex participated in WorkAdvance in the fall of 2019 through MVMC. The coalition and West Central Job Partnership of Pennsylvania were awarded a $2.5 million workforce development grant from the U.S. Department of Labor.

Almost 30 students with a mechanical aptitude were initially picked for the TCTC program, but were soon whittled down to five as Karlovic met with their parents through a Zoom meeting.

Talking with Wess were senior Madison Chura, an electrical technology student originally from LaBrae High School; along with senior Alexander Boorn, an auto service technology student hailing from Champion High School.

“All five really knew nothing about manufacturing, so they were taking a blind leap of faith in just trusting me that I wouldn’t steer them wrong,” Karlovic says. “These three have done fantastic with the opportunity.”

The five interviewed for positions and would start working at the North Jackson business later this month.

Extrudex is about 20 employees short of its 200 capacity for the second-largest area for aluminum extrusion in the United States, says general manager Jim Scheuing.

Many employers are struggling to hire new workers as the minimum wage is being raised at most retail businesses and eateries. Starting around $13 an hour at Extrudex, not a fast-food place where there is not likely advancement, can be the hangup of most job seekers, Karlovic says. This WorkAdvance program could be a growing career to these five — adding they could make up to $18 to $20 an hour.

“They wouldn’t just be grunts on a floor,” she says. “They would be mechanics working on really expensive machinery and doing really cool things everyday.

“I guess I would just want people to look past what’s right in front of them and kind of look down the road to the future — get invested now in a company that is desperate for workers and that wants to invest in you as an employee.”

Advancement is possible as these TCTC students can go from stacking metal to general manager, along with learning the technical end of extrusion as well as some of the sub equipment, such as aluminum structure, press operator and eventually ending up as the lead supervisor. Another route is through the quality control department if these high school seniors have technical skills, Scheuing says.

Working in the fabrication department, running technical metal saws, cutting finish lengths, running fully automated extrusion lines and taking metal off and packaging are some of the tasks.

“They will get entrenched in the wonderful industry of aluminum extrusion with Extrudex,” Scheuing says. “The big thing is obviously being here and getting involved in our process.”

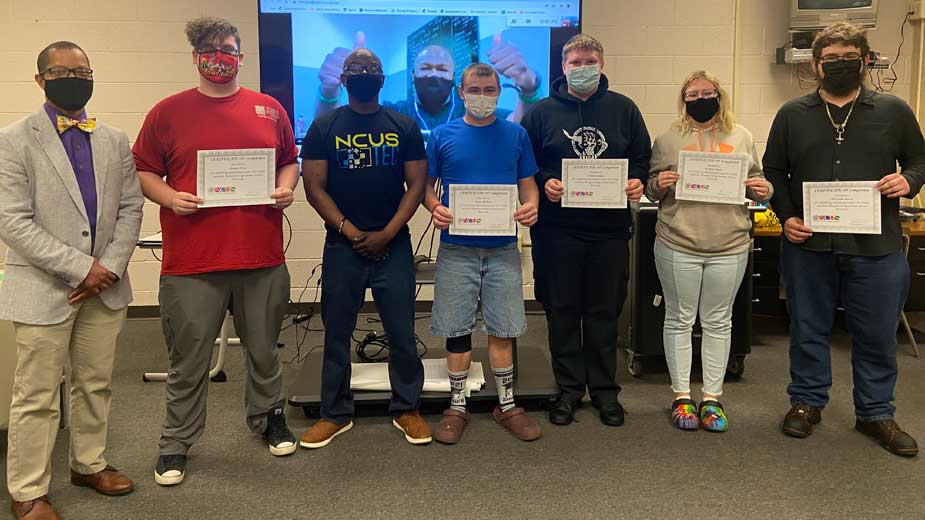

Plenty of online classroom learning followed as the five pupils completed tests and modules — passing three Manufacturing Skill Standards Council Certified Production Technician certifications. The final one would be at Extrudex involving safety, quality practices and measurement, manufacturing processes and production, along with maintenance awareness.

No hands-on training was provided.

“I would like to do hands-on stuff so I know what I’m getting myself into,” Chura says.

Nonetheless, the trio of students utilized their previous knowledge at TCTC, applying it to this WorkAdvance program.

Simple things such as using a wrench wasn’t an issue for Chura, who learned those skills at home.

“When we finally got to the fourth module there was more stuff about the electrical program and electrical maintenance [that] I’ve already learned in my class,” she says.

Safety was never an issue for Wess, who is OSHA certified.

“A lot of the questions were almost exact to the OSHA and a lot of the aptitudes I got with hand tools and power tools,” he says. “That transferred over to manufacturing.”

Measurements with a chronometer and calipers were easy for Boorn.

“We also covered [tap and die], which is something we’ve done on the auto service program,” he says.

Either Extrudex will have a lead to show these newbies the skills necessary to be a productive member of the company or possibly go through an apprenticeship with the maintenance department, Scheuing says.

“Maybe a couple of them have interest in going into that field?” he adds.

Drill presses and those sorts of things interested Boorn because he doesn’t see those much in his auto service background, as the Champion native is accustomed to wrenches, ratchets and hammers.

“I learned a lot about machinery,” he says.

“There’s certain machines that go vertical and certain machines that go horizontal and pick out which one we need to use,” Chura adds.

The best part was learning about teams and how different areas of production problem solve, figure out solutions, or a “better way to do things,” says Wess, who says he was educated about welding and electrical studies.

Each of these students have a career coach through Goodwill that stays with them for a year, even if they don’t stay with Extrudex or look to apply for advancement in the company, Karlovic says. Employability coaches worked on team building, communication, interview skills, resume writing and other essential skills.

“It was a very holistic program, and I think that’s why I was so excited about it for the students,” she says. “But that is for everyone in Extrudex, so even adults get those services as well.”

The TCTC grouping impressed Scheuing, saying they were a great group and hopefully have a long career with Extrudex. The skills they will learn can lead to many other positions, saying what these students learn are transferable to other extrusion operations as they grow in their careers.

Chura, being a female in a male-dominated program, says she has had nothing but great experiences during her time at TCTC — expecting those to continue as she enters her professional career.

“I’ve made male friends,” she says. “They’re kind of my team now. They work with me, and they’re always there for me.

“So I plan to take that somewhere and keep making friends and keep meeting new people. And hope that they still have respect for me and don’t discourage me just because I’m female because I do want to work and I do want to learn things.”