Credentials Training Yields Job-Ready Talent

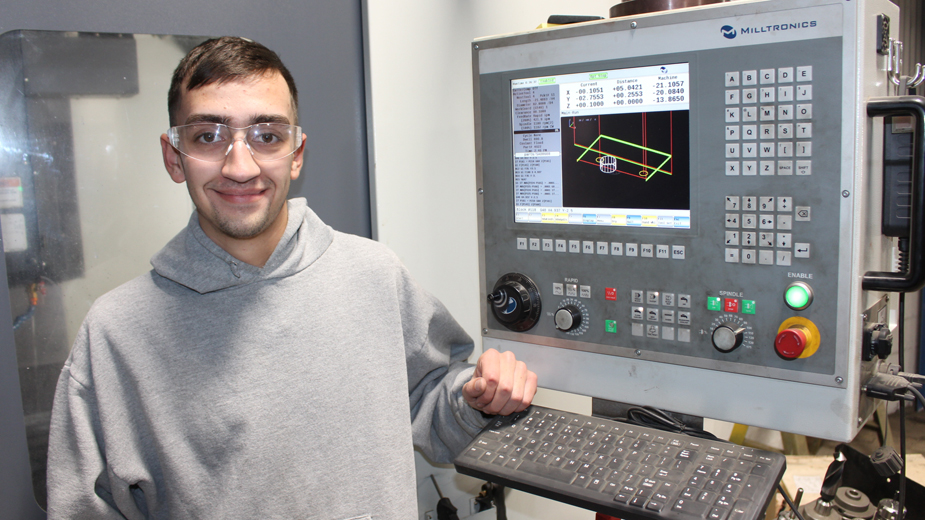

SALEM, Ohio – Working alongside men twice his age, Zachary Bush has a confidence that belies his youth.

The 18-year-old senior at United High School, Hanoverton, spends his days at the Columbiana County Career and Technical Center in its precision machining and manufacturing program. As classes allow, he also works as one of two machinists at Salem Welding & Supply.

Despite his youth, he doesn’t shy away from a challenge. “Give me a pallet of parts and a bunch of prints and I’ll make them,” he says.

One recent challenge involved building a mining truck bracket that included electronic components. Because Salem Welding is a job shop, typically no two projects are alike. So the part was made from scratch.

The shop foreman, Paul Saling, gave Bush the plans and rough metal parts. He then programmed his CNC machining equipment for the entire job.

“There was a bunch of different setups and we weren’t sure if it was going to work,” Bush says. “It turned out in the end it worked perfectly and the customer loved it.”

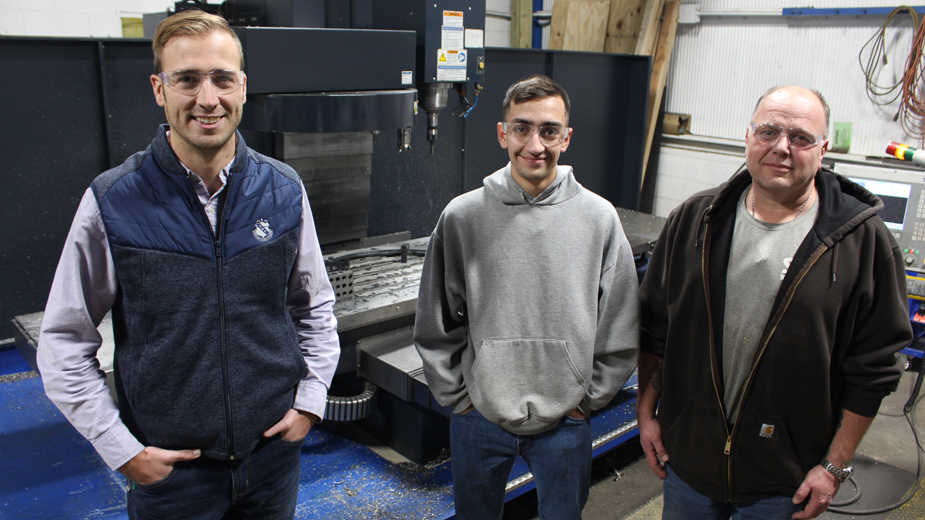

Saling commended Bush’s self-motivation and for getting jobs done correctly. Having worked in a one-off, job shop environment for most of his professional life, Saling understands the challenge in training someone who has built the same part for years.

“Bringing people in while they’re young and teaching them is a lot better than having somebody learn something wrong throughout their life. It’s a lot easier to teach somebody the first time.” he says. “Zach has been 100% awesome. He’s come out of school with a lot of information, a lot of knowledge.”

Bush prefers to work with his hands and enjoys putting what he learns at CCCTC into practice, he says. The skilled trades were a natural fit for Bush, whose grandfather and father worked as an engineer and machinist, respectively. His older brother is in college pursuing a degree in engineering.

“I’d much rather be standing up doing something than sitting in a classroom taking classes that I’m not going to use,” he says. “Especially being 18 years old. Some of my buddies don’t even have jobs yet and I’m making a future for myself already.”

Bush is the first high school student to participate in the group-sponsored apprenticeship program through the Mahoning Valley Manufacturers Coalition, says its executive director, Jessica Borza. MVMC developed the program alongside its manufacturing and education partners to give members access to apprentices without incurring the cost of developing their own programs, she says.

Through training at CCCTC, students earn National Institute for Metalworking Skills, or NIMS, credentials that are “perfectly aligned with credentials that are a part of the apprenticeship program,” Borza says.

Credentials demonstrate competence in lieu of hours completed. So Bush’s apprenticeship can be completed in one or two years instead of the typical four.

“We use the credentials as a measure of the competencies that the apprentice has mastered,” Borza says. “That gives us quality assurance that Zach has a full understanding of what those credentials have covered.”

That’s a boon to Salem Welding, which branched out into machining a few years ago, says its vice president, Tom Baker. Having local entities like CCCTC and MVMC create a pipeline of young talent trained by trusted instructors helps with hiring and saves the company money in training costs.

“Hiring is one of the hardest parts of the business,” Baker says.“When my main focus is on running the business and trying to sell things from out of here, hiring can oftentimes be a hassle for us.”

When Salem Welding was founded in 1975 by his grandfather, Fred Baker Sr., the company focused solely on welding and fitting.

Under the leadership of Tom’s father and company president, Fred Baker Jr., Salem Welding continued to expand at its Prospect Street location. The company increased its main shop space to 40,000 square feet and purchased in 2016 a 10,000-square-foot space across the street. Today, it serves customers in the tri-state area and Michigan, particularly in the oil and gas, steel, mining, materials handling and telecommunications industries, Baker says.

Yet anytime an opportunity came up for a job that required machining, “we either didn’t bid on it,” or had to subcontract part of the work to other vendors, Tom Baker says.

At the behest of one customer, Salem Welding expanded its capacity so it could complete jobs from start to finish, he says. In 2018, the company bought its first computer numerical control, or CNC, machine.

“For the first six months, it went fantastic,” he says, prompting the company to buy two more CNC machines – an investment of some $300,000 with another $30,000 to $50,000 in tooling and measuring equipment.

But finding individuals skilled in CNC machining was a challenge for the company, which had never hired machinists before, he says. In addition to machining skills, the company wanted to hire younger people to fill positions, he says.

“I’ve always thought it’s good to hire a younger person, someone that’s either 17 or 18,” he says. “It’s an aging workforce. A lot of our employees are over the age of 50 and some are approaching 60, 65.”

Bush came in from the CCCTC “super knowledgeable” in machining, Baker says. Shortly after starting his apprenticeship at the company, Bush began familiarizing himself with the equipment and learning how to run it. A few months later, he was reading prints and programming jobs on his own, Baker says.

“Now, I can give him a skid of material and a job packet and he’s pretty much able to do the whole thing as far as programming, running it, cleaning it, [quality checking] it and getting it ready to ship,” he says.

Machining accounted for a 20% increase in business at Salem Welding, “and it seems to keep increasing,” Baker says. Between Bush and a second machinist, the shop does about 45 hours a week of machining work.

The only thing preventing even more growth is a need for more equipment and machinists, Baker says. After the new year, he expects things to pick up again and looks to hire a few machinists and buy a few more machines. The company employs 25.

“It’s a matter of getting machines in here and finding the right people,” he says. Baker plans to stick with the MVMC’s apprenticeship program for machining and welding hires, he says.

Currently, 260 apprentices are going through the program and the MVMC is getting positive feedback from member companies, Borza says. Although grant funding for the program ends September 2021, she says continuing the program is one of the organization’s top priorities and affirms it has resources in place to do so.

“Companies are using apprenticeships to show somebody like Zach that it’s not a dead-end job and they will continue to invest in them and support their growth,” she says.

And that’s something Bush will take advantage of. While he plans to stay here and work at Salem Welding, he looks to add to what he’s already learned by attending a trade school.

“The career center pushes you going to college or a trade school,” he says. “They don’t want you just to do the two years and stop. They want you to keep growing to be the best person you can be and learn the most you can about your trade.”

Copyright 2024 The Business Journal, Youngstown, Ohio.