How 3D Printing Can Address the Labor Shortage

The shortage of labor in the skilled trades sector is at an all-time high, stemming back even before COVID-19 spotlighted this issue.

Skilled trades are in need of qualified workers, but due to an aging workforce and a lack of new tradesmen, they are seeing a major deficit across the industry.

The current workforce is working longer hours to combat the shortcomings of skilled laborers; this is causing earlier burnout and low employee morale.

A recent study by Michigan State University forecasted a global manufacturing labor shortage of 8 million people by 2030. This equates to an expected revenue loss of over $600 billion.

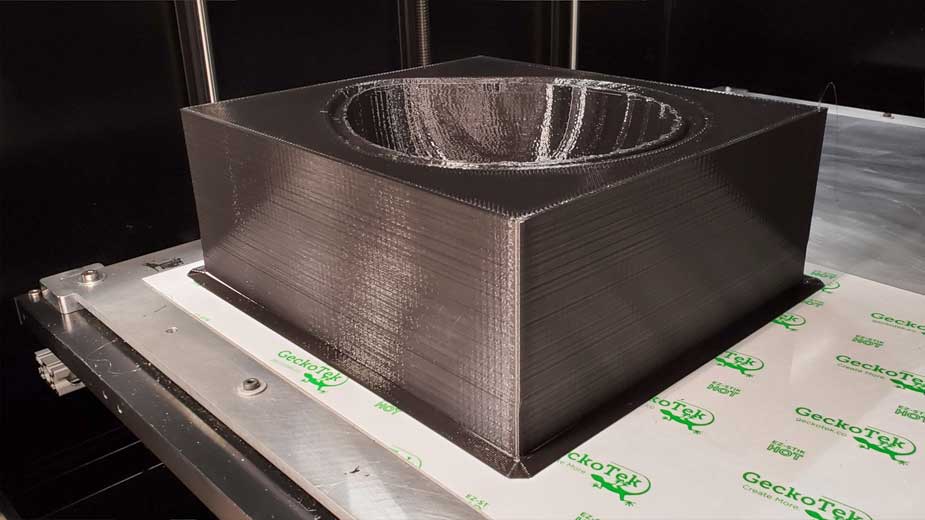

However, there is a bright spot for skilled trades globally. 3D printing has both the scalability and functionality to drastically improve modern manufacturing and decrease the national labor shortage.

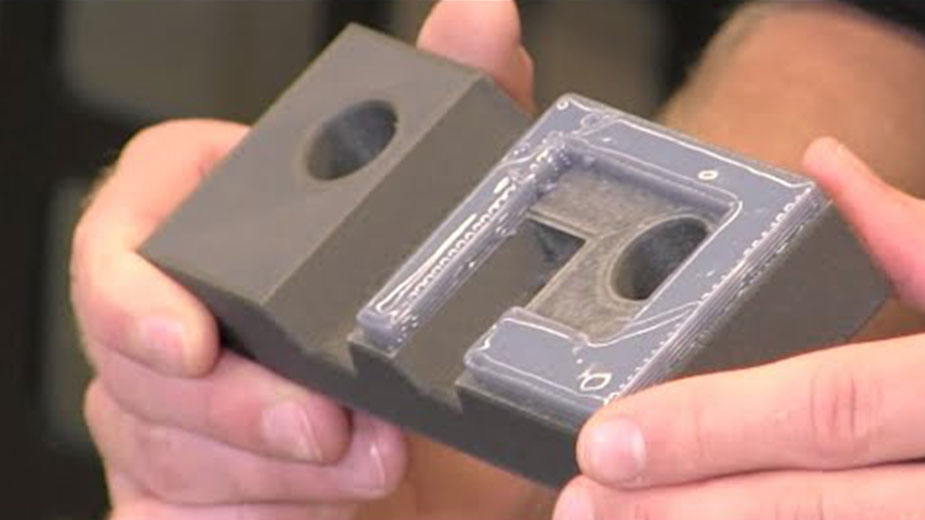

One company, JBM Technologies, has leveraged 3D printing to enhance their offering, scalability, and capabilities for their clients.

JBM Technologies chose JuggerBot 3D after scouring the globe looking for all available additive manufacturing technologies. For them, the choice came down to a few distinct characteristics; most companies had the size, but none of them had the robustness, quality, and actual industrial capability that the 3D printers at JuggerBot 3D have.

To learn more about JuggerBot 3D Tradesman Series™ Models, click here.

In the skilled trades, lean manufacturing and driving down costs is critical to long-term success. The additive manufacturing technology is what will allow companies to drive down costs and hone in on that lean manufacturing model.

Ready to get started with 3D printing? Click HERE for the Tools of the Tradesman!

Copyright 2024 The Business Journal, Youngstown, Ohio.