Li-Cycle Expands Partnership with Ultium Cells

TORONTO & DETROIT — Li-Cycle Holdings Corp. announced Thursday plans to operate its sixth and largest lithium-ion battery recycling Spoke facility at the $2.3 billion Ultium Cells LLC electric-vehicle battery cell manufacturing plant under construction in Lordstown.

This new Spoke “continues Li-Cycle’s strategic execution and focus on growing its integrated Spoke & Hub network in North America, including through commercial partnerships,” the company stated in a press release. The Spoke plant will be co-located on the same site as the Ultium Cells plant and will support Li-Cycle’s multi-year agreement with Ultium to process its battery manufacturing scrap.

“We’re thrilled to collaborate on this inaugural facility co-located at a key customer site,” Ajay Kochhar, president, CEO, and co-founder of Li-Cycle, said in the release. “Building this Spoke facility alongside Ultium Cells’ plant is expected to substantially optimize costs and logistics as we transform manufacturing scrap from the plant into highly valuable material, using our unique, sustainable and fit-for-purpose approach.”

Ultium will construct a new building for the Li-Cycle recycling facility, and Li-Cycle will install and operate its proprietary Spoke technology and equipment there.

Once complete, Li-Cycle’s Ohio Spoke facility will have the capacity to process up to 15,000 tonnes of battery manufacturing scrap and battery materials per year, bringing Li-Cycle’s total global recycling capacity to 55,000 tonnes of lithium-ion battery input per year, according to the release. The Spoke facility is expected to be operational in early 2023 and is anticipated to create at least 35 new jobs.

The primary output product of the Spoke will be black mass, a powder-like substance consisting of a number of highly valuable materials, including lithium, cobalt and nickel, which Li-Cycle will convert into battery grade materials at its Hub facility in Rochester, New York, scheduled for completion in 2023, the company stated.

Ultium announced in May that it had struck a partnership with Li-Cycle.

“I think it’s great,” says Lordstown Mayor Arno Hill. “They want to be an asset to the battery plant and hopefully will bring other businesses to the region.”

Hill says the Ultium plant could help lure other potential suppliers to the region.

“There are a couple other companies looking,” he says. “We’ve been dealing with one for about six months. But they run hot and cold.

“It’s great for the village hopefully success breeds success.”

Li-Cycle expects its Ohio facility to substantially reduce the costs associated with moving and handling battery manufacturing scrap materials, given its proximity to Ultium. The new Spoke facility will also be optimized for the particular types of battery manufacturing scrap generated at the Ultium Cells plant, enhancing production efficiency, according to the release.

“Our collaboration with Li-Cycle is an instrumental step in improving the sustainability of our components and manufacturing processes. This facility is another bold step forward in our sustainability journey here at Ultium Cells,” said Kevin Kerr, Ultium Cells Ohio plant director.

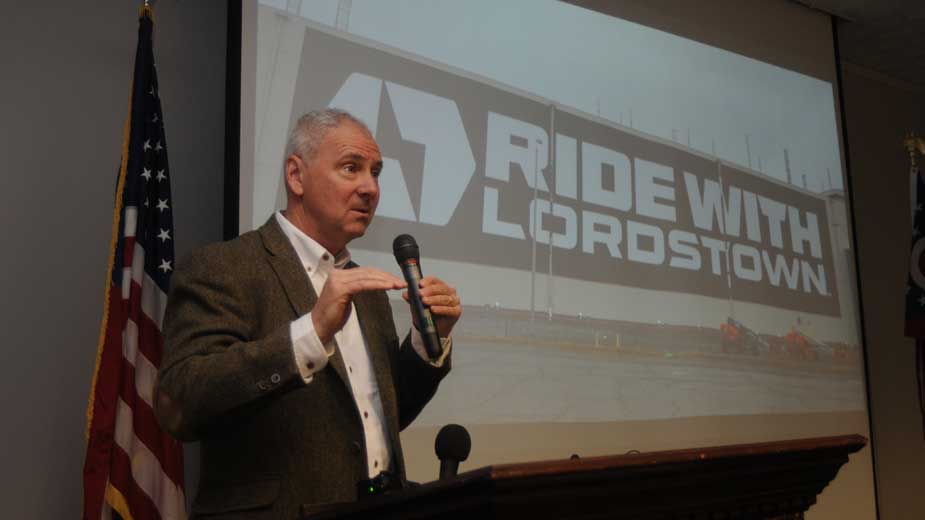

Pictured: Ultium Cells LLC rendering

Related News:

Jan. 12, 2022 | Recycling Operation Could Be Next for Ultium Site

Copyright 2024 The Business Journal, Youngstown, Ohio.