MVMC, Career Center Offer Training in Robotics, Automation

YOUNGSTOWN, Ohio — New education courses will gives area manufacturers an opportunity to get new and existing workers trained to fill in-demand automation and robotics jobs.

In talking with manufacturers, the Mahoning Valley Manufacturers Coalition has identified a growing trend toward automation as the labor market tightens, says its executive director, Jessica Borza. Employers are determining what processes can be automated, freeing up workers to “focus on more highly skilled needs or functions,” she says.

This trend is leading to a need for skilled programmers and technicians to operate the technology. With few, if any, training courses available, many employers are left to figure things out on their own, she says.

“Many of the companies are basically creating their own training programs from within,” Borza says. “What we know is that there is a real lack of existing training. We know this is true across the state.”

In an effort to help meet that need, the coalition is working with the Mahoning County Career and Technical Center and a core group of area employers to determine what that training looks like. An event from 1 to 2:30 p.m. on Jan. 16 at MCCTC Ramtec Laboratory Door No. 52, 7300 N. Palmyra Road, Canfield, will give employers a chance to hear about potential training, offer their feedback and learn of available funding to pay for the courses.

Anyone interested in attending the event can RSVP with Sue Watson at swatson@tpma-inc.com.

With its existing equipment and instructors, MCCTC provides “a good foundation” to build from for this type of training, Borza says. Speaking with employers will help shape the programming, which Borza hopes to launch in the spring, she says.

“We want to listen to what they’re seeing and what their needs are. We will talk to them a little bit about what the school is capable of doing and what kind of equipment they have,” she says.

Five years ago, MCCTC received a $500,000 grant through the Ramtec Consortium and added another half million in investments to get started in the robotics arena, says superintendent John Zehentbauer. Employers have been mostly interested in robotic welding, hydraulics, pneumatics and, particularly, industrial maintenance, he says, though he expects the scope to expand as more embrace automation and robotics.

“This area is really just starting to ramp up,” Zehentbauer says. “We’re starting to see industrial maintenance is a big weakness in this area; people who fix the machines that make stuff.”

Adult education classes at MCCTC can be customized based on the employer’s specific needs, he says. Whether it’s a company-wide instruction at MCCTC or a certain number of hours of training at the employer’s shop to get credentials for a few individuals, the curriculum and cost are flexible.

Funding through the Ohio TechCred program makes it easier for employers who need the training but can’t afford to hire instructors, he says. MCCTC recently hired someone to assist employers in filling out the application paperwork for the funding.

“You’ve got small companies who don’t have a big training budget. A lot of them are not aware of it,” he says. “If you’re a company and you look at all the lists of credentials, you can get your employees trained for free to make a better workforce.”

There are two funding sources accessible to companies, through the Ohio TechCred program, and both will be discussed at the event, says MVMC’s Borza. The first pays for the cost of credentialing and the second helps with the cost of training itself.

Eligible companies can receive training cost reimbursement of up to $2,000 per credential, with one reimbursement available per employee in each funding round, according to program documents. Employers are eligible to receive up to $30,000 per funding round.

While individuals can receive credentials to operate large, industrial robots that can take the place of four or five works on an assembly line, Zehentbauer says he’s seeing increasing interest in co-robots, which work with the existing workforce.

Regarding any underlying concern that automation will replace workers, Borza says the trend toward automation in the area is “quite the opposite,” and will actually create more jobs as employers hire skilled technicians to work with the robots.

“I think it’s just a natural evolution. We’re always trying to increase productivity. As technology has improved, it’s just a responsible thing for manufacturers to explore,” Borza says. “It doesn’t mean less people. It means different kinds of jobs.”

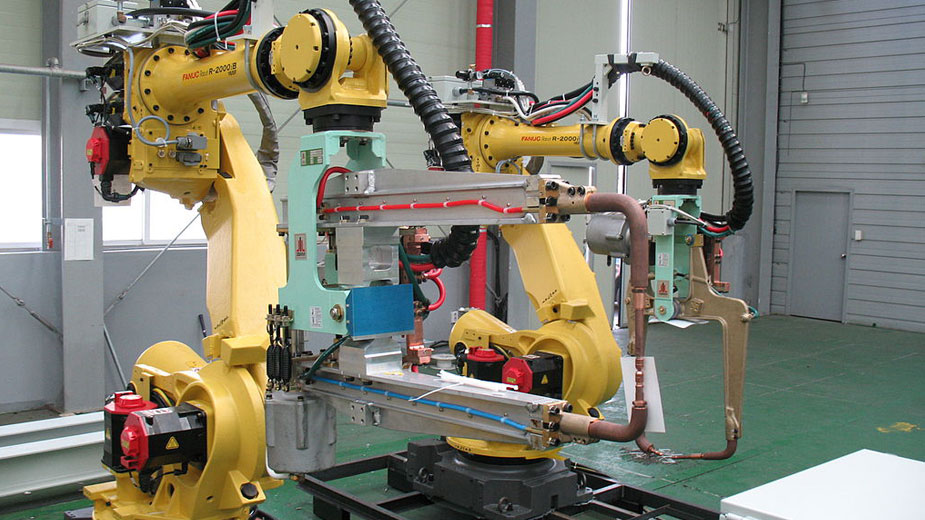

Pictured: Among the credentials offered include those for using Fanuc robots. (Image: Mixabest [CC BY-SA])

Copyright 2024 The Business Journal, Youngstown, Ohio.